UPENDERS AND TIPPER MACHINES

In industries dealing with large, heavy loads like metal coils, molds, and dies, effective handling solutions are essential. Mechanical upenders and coil tippers, such as those offered by Fhopepack, play a vital role in facilitating safe, efficient handling and positioning of these hefty items. Designed for durability and reliability, these machines cater to industries that regularly maneuver cumbersome, heavy loads, reducing risks associated with manual handling. This article explores the key features, design options, and applications of Fhopepack’s mechanical upenders, offering insights into how they can be customized to suit specific industrial needs.

Standard Features of Fhopepack Mechanical Upenders:

- Mechanical upenders come with several essential features that make them indispensable in heavy-load handling. These features reflect the robustness and versatility of Fhopepack’s designs, ensuring safe and effective handling of items across various weights and sizes

-

Load Capacities Ranging from 3,000 to 100,000 Pounds:

Fhopepack’s mechanical upenders are designed to handle loads of varying sizes and weights, with capacities ranging from 3,000 pounds for lighter applications to an impressive 100,000 pounds for extremely heavy loads. This wide range of capacity options makes these machines suitable for diverse applications across industries, from automotive and aerospace to metalworking and logistics.

-

Robust Welded Steel Construction

The foundation of any mechanical upender’s durability is its construction. Fhopepack employs robust welded steel for the mainframe of their upenders, ensuring that they can endure the stresses and demands of heavy-duty industrial applications. This type of construction offers:

· Enhanced Stability: The solid steel construction helps maintain balance and reduce vibrations during operation.

· Long-Term Durability: Welded joints add strength to the frame, minimizing the chances of structural wear over time.

· Minimal Maintenance: The robust structure requires less frequent maintenance, reducing downtime in busy industrial environments.

-

Safety Features and Compliance Standards

Safety is a primary concern in handling equipment. Fhopepack’s upenders are equipped with safety features like emergency stop buttons, safety covers, and warning indicators. These additions ensure that operations are not only efficient but also safe for operators, aligning with industrial safety standards and regulatory requirements.

Upenders

-

customized coil tilterWe offer a range of steel coil tilters, each with their own customized services and comprehensive technical support. Choose from our professional mold tilters or mechanical coil tilters with customizable services, or opt for our coil upender with turntable rotary tilter. We also offer hydraulic 90 coil tilters with adjustable wor...

-

coils tiltersOur upenders offer versatile solutions for both production and maintenance applications, and are customizable with a range of options to suit your unique needs. Choose between our two types of upenders, mechanical and hydraulic, to find the best fit for your operation. Check out our related pictures, including upender/tilter + co...

-

hydraulic upenderA hydraulic upender (also known as a hydraulic tilter or hydraulic coil upender) is a machine that uses hydraulic cylinders to lift and rotate heavy or awkward objects from a horizontal position to a vertical position. They are commonly used in the manufacturing and processing industries to facilitate the handling, storage, and t...

-

mechanical upenderOur mechanical upenders, also known as coil positioners, offer efficient rotation of steel coils and other loads up to 90 degrees in either direction. We offer two types of upenders, mechanical and hydraulic, to ensure that you have the best solution for your application. With our mechanical upenders, you can optimize your produc...

-

customized hydraulic coil upenderA hydraulic coil upender is a machine that uses hydraulic cylinders to lift and rotate coils of material, such as steel or aluminum, from a horizontal position to a vertical position. They are typically used in the manufacturing and processing industries to facilitate the handling, storage, and transportation of these materials.W...

-

china movable coil upender tilterOur high-quality double-acting tilt cylinders efficiently rotate the platforms, powered by an industrial-duty motor, hydraulic pump, valve system, and oil reservoir. These components are expertly embedded within the unit or packaged for external mounting, ensuring reliable and efficient operation. With our tilt cylinders, you can...

-

low price coil upender tilterOur hydraulic upender platforms are designed to handle a diverse range of load configurations, including long loads like paper rolls or other materials with a length significantly greater than their width or diameter. With our upender platforms, you can efficiently and safely handle your unique loads, no matter their shape or siz...

-

used coil upendersOur upenders are a versatile solution for both production and maintenance applications, with multiple options available to customize them to your specific needs. Choose between our two types of upenders, mechanical and hydraulic, to find the ideal fit for your operation. With our reliable and efficient upenders, you can optimize ...

-

hydraulic upenders manufOur hydraulic upenders are adaptable to various systems and feature automatic operation for molds, rollers, coils, and more. We offer two types of upenders: mechanical and hydraulic. Choose from our selection of hydraulic upenders to find the perfect solution for your application. With reliable performance and easy operation, our...

-

customized upenders tiltersAn upender (also known as a tilter or a coil upender) is a machine that is used to rotate heavy or awkward objects from a horizontal position to a vertical position. They are commonly used in the manufacturing and processing industries to facilitate the handling, storage, and transportation of materials such as steel coils, drums...

-

customized roll upenderOur roll upenders come in different versions for handling paper, carpet, curtain, and other rolls. Depending on the factory, there may be various ways to shift the roll position from the production line to the workhouse or to load and unload from storage or cars. Regardless of your handling needs, our roll upenders provide the ve...

-

customized coil upendersThe upender provided to lift coil material typically comes with a V-bracket mounted on one of the platforms. This cradle supports the circular cross-section material and prevents lateral rolling when in a horizontal position. For units used at the lower end, the platform serves as the offload platform. Those without a V-bracket c...

-

customized coil upenderOur customized coil upenders are tailored to meet your unique needs and requirements. From specific load capacities to handling coils of a particular size or shape, we design the features you need. Our specialized features ensure that your application is handled with precision and efficiency. Trust us to deliver a customized solu...

-

mechanical upendersWhether you need a standard configuration or a custom-engineered solution, mechanical upenders are versatile tools for your application. For floor applications, use the chalk line on the platform to measure hoist position. Heavy-duty, welded steel construction forms the frame, while four or more precision machined steel rolls wit...

-

china mechanical upendersThe China coil tilter is fully electrically controlled, with an isolating switch and button station mounted on the unit. To ensure safety, lift the platform and disengage the maintenance safety bar. The limit switch automatically controls rotation. Before use, it's crucial to wear protective equipment, follow manufacturer instruc...

-

Chinese coil tilter manufacturer / Upender / steel coil/Companies that specialize in handling and processing steel coils typically offer a variety of machinery, such as coil tilters, cranes, and other material handling equipment. In addition to these standard products, they may also provide customized solutions to meet specific customer requirements. With their expertise in the indust...

-

upender machineLoad upenders are available in various structures and driving mechanisms that are customized to fit specific load sizes, shapes, and moving tools or kits. To ensure that the machine is designed to meet the user's needs, it is essential to provide all necessary information during the communication and purchasing process. This step...

-

china roll upenderWhen looking for a Chinese manufacturer of upenders, it is crucial to conduct thorough research and compare different companies to find the best fit for your needs and budget. Factors to consider include the quality and durability of the machinery, the level of customer service and support provided, and the reputation of the comp...

-

manual drum upenderThe manual drum upender is a customized mechanical upender that comes equipped with tie-down bars to secure molds during the upending process. Its extra-wide platform is designed to accommodate larger loads, making it a versatile solution for a wide range of industrial applications. With its innovative design and reliable perform...

-

customized hydraulic upenderThe hydraulic upender features a U-shaped saddle and a powered conveyor. It is specifically designed for indoor applications, with various models available that differ in capacity, lift height, and platform size. While all models share a similar design, each is tailored to meet the specific needs of different customers. Whether y...

-

Mobile pallet turnerThe Fhope mobile pallet inverter is a highly useful equipment for warehouse handling. It is designed for easy movement and tilting of pallets with the help of a hydraulic cylinder that can handle heavy loads. The machine allows for manual rotation and pallet change, which enhances workers' efficiency. Its reinforced structure and...

-

Steel sheet upenderThe steel sheet upender and tilter is a crucial machine in the steel industry. It features a C-shaped turnover body that is motor-powered to flip piled steel sheets up to 180 degrees. To load the products, a forklift is required. The machine can also be adapted to a semi-submersible layout, where it is placed in a pit on the floo...

-

Precast slab upenderA precast slab upender flips slabs rapidly yet carefully, expediting installation while preserving safety. It handles large, heavy slabs, improving a manual process prone to injury or damage. Manual slab flipping proves perilous and time-consuming. Upenders transform this through automation, delivering economical efficiency a...

-

Die&mold flipperMold flipping upenders invert molds rapidly yet carefully, enabling material pouring and sealing. They handle heavy loads, up to 60 tons, with precision, accuracy and ease, ensuring worker safety. Two versions facilitate mold flipping: 180-degree and hydraulic upenders. 180-degree upenders flip molds 180 degrees for minimal cont...

-

Die flipper for Die and mouldDie flippers invert molds swiftly and surely without damage. Two versions assist in handling and flipping heavy molds up to 60 tons: 180-degree flippers and hydraulic systems. 180-degree flippers flip molds 180 degrees, minimizing contact. Hydraulic systems harness pressurized oil to flip, rotate or tilt molds up to angles for...

-

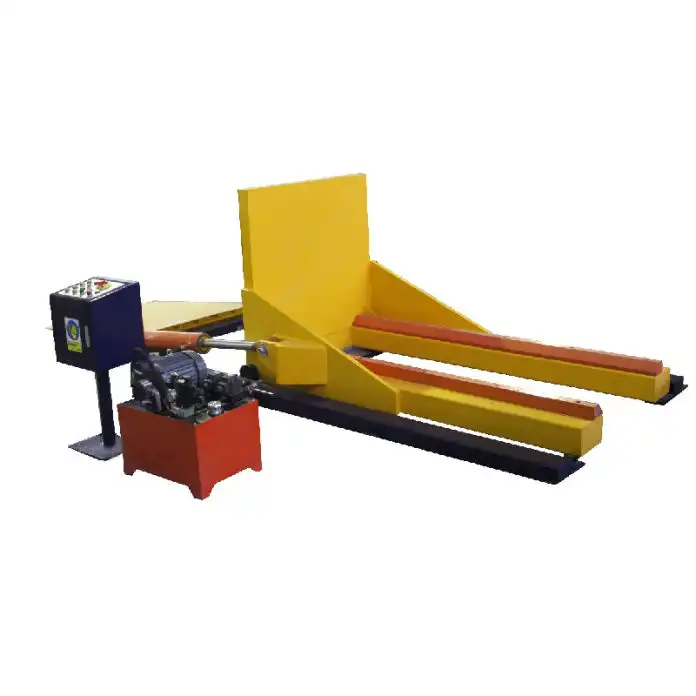

Tipper on stockCOIL TIPPER FOR SALE FHOPE is responsible for the design and manufacture of the vertical one-piece turning equipment and performs all manufacturing processes and commissioning steps. Fhope's main business is to provide packaging equipment for the steel industry, construction industry, and food and beverage can industry.Steel cons...

-

Mold Upender machine 5TA mold upender inverts molds precisely for filling and sealing. It handles heavy loads with care and control. Mold upenders expedite manufacturing by automating a manual process. They flip molds swiftly yet steadfastly for efficient, consistent work. Uprighting molds as quickly and steadily as overturning them, upenders minimi...

-

Mold Rotator | for mould and Die handlingA mold rotator rotates molds controllably for manufacturing processes. It casts, forms or shapes materials into desired shapes by pouring into molds until set.Steady, consistent rotation distributes materials uniformly, resulting in more uniform, consistent finished products. The rotator enables economical production of high-qual...

-

Moldtech tilting tables for precast manufacturersAn ideal surface requires grinding the table. Shuttering forms in diverse sizes and thicknesses facilitate elements with openings for doors and windows.High-frequency vibrators compact freshly poured concrete. Heating systems expedite curing by fitting the table.Hydraulic telescoping cylinders tilt the table, enabling safe, secur...

-

Tilting table for flat precast concrete elementsTilting tables are integral to producing large, level precast concrete elements efficiently. The ground table surface ensures an optimal finish. Shuttering forms of various sizes create openings for doors and windows. High-frequency vibrators compact wet concrete thoroughly. Heating systems can accelerate curing. Hydraulic tel...

-

Board and panel upender for MDF| Sandwich | woodenBoard and panel Upender for MDF Brief Introduction: A heavy Capacity load inverter was created to rotate a maximum load of 5 tons by 180 degrees. Its design includes a durable hydraulic cylinder to press and fix production position to ensure safety and facilitate a smooth. The power motors robustness allows it to handle heavy loa...

-

5T steel coil upenderThe FHOPE 5T Steel Coil Upender, designed to handle up to 5 tons, ensures safe and efficient coil reorientation. Featuring robust construction, variable speed control, and enhanced safety mechanisms like emergency stops, this device is an essential tool for heavy-duty material handling, finished in Green Valley Gold....

-

Mold Rotator | Mould Rotating MachineThe Mold Rotator is an essential tool designed for the precise and safe rotation of molds in manufacturing. This device enhances workflow efficiency by facilitating easy mold handling and positioning, thereby reducing labor costs and improving product consistency in industries such as casting and molding....

-

Stationary UpendersStationary Upenders are engineered for safe and efficient repositioning of heavy and bulky loads. Ideal for industries requiring the rotation of coils, dies, and other materials, these upenders provide a 90-degree tilt, enhancing workflow and reducing labor strain. Built with robust materials, they ensure durability and reliabili...

-

Coil Upender For SaleThe Coil Upender for Sale is designed for heavy-duty applications, efficiently flipping large coils from horizontal to vertical positions. This equipment enhances safety and productivity in facilities handling metal coils, providing a reliable and robust solution for material manipulation....

-

Coil DownenderThe Coil Downender is an essential device for safely and efficiently reorienting heavy coils from vertical to horizontal positions, enhancing material handling in manufacturing environments. It supports loads up to 5,000 lbs, offering adjustable speed controls and robust, durable construction for long-term reliability....

-

Battery UpenderIntroducing the Battery Upnder, a revolutionary device designed to automate and streamline the process of flipping batteries. This machine enhances efficiency and safety in production lines, ensuring precise handling and optimal performance in battery manufacturing and recycling operations....

-

Mold Rotator, Mould Rotating MachineThe Mold Rotator and Mould Rotating Machine are essential tools in industrial settings for the precise and controlled rotation of molds. These machines enhance productivity and safety by facilitating the easy handling and manipulation of various mold sizes, ensuring uniform casting and cooling in manufacturing processes such as p...

-

Steel Sheet Upender, Steel Sheet InverterThe Steel Sheet Upender and Steel Sheet Inverter are designed for the safe and efficient handling of large steel sheets, facilitating easy rotation and precise positioning. These machines are essential in manufacturing environments, reducing strain and improving workflow by streamlining the movement and storage of steel sheets....

-

Die & Mold Flipper Solution ManufacturerDie & Mold Flipper Solution Manufacturer specializes in designing and producing innovative equipment for safely and efficiently flipping heavy dies and molds. Our solutions enhance workflow, reduce downtime, and increase workplace safety, catering to industries such as automotive and precision engineering....

-

Movable Coil Upender Tilter, Hydraulic Upender ManufacturersThe Movable Coil Upender Tilter and Hydraulic Upender Manufacturers offer robust equipment designed for safe and efficient handling of heavy coils. These systems ensure precision and flexibility in industrial environments, enhancing productivity and safety....

-

Mold Flipping Machine For saleThe Mold Rotator for Mould and Die Handling is expertly designed to facilitate the safe and efficient rotation of molds and dies, enhancing workflow and reducing manual labor in industrial settings. It supports precise positioning and handling, ensuring operational safety and reliability....

-

Die & Mold FlipperThe Die & Mold Flipper is designed to efficiently handle and rotate heavy dies and molds. This equipment ensures safe operation and precise positioning, significantly reducing manual effort and improving productivity in industrial environments like manufacturing and tooling facilities....

-

Customized Hydraulic Coil UpenderTop 6 Things to Choose a Customized Hydraulic Coil Upender Handling heavy-duty materials like coils in industries such as steel, aluminum, and wire manufacturing is no small feat. The process of tilting and positioning coils can be labor-intensive, time-consuming, and fraught with safety risks. That’s why investing in a hydraul...

-

Coil Tipper PriceThe Coil Tipper Price offers a cost-effective solution for efficiently handling and tipping heavy coils in industrial settings. Engineered for durability and safety, it supports various capacities and features customizable options to meet specific operational needs. Ideal for enhancing productivity in metalworking facilities....

-

Manual vs. Automatic Coil Upenders: Which Offers Better ROI?Choosing between manual and automatic coil upenders is a key decision for optimizing return on investment (ROI). This article explores both options, focusing on cost, efficiency, and long-term advantages. While manual upenders require less initial investment, automatic systems offer increased productivity, lower labor costs, and ...

-

Evaluating Steel Coil Upenders Based on Load Capacity and EffChoosing the right steel coil upender requires a thorough evaluation of both load capacity and efficiency to ensure it meets your operational demands. By selecting a machine that balances these factors, you can improve workflow, reduce manual labor, and enhance safety. This guide provides insights into how load capacity and effic...

-

Coil Tilter Warranties: What You Should ExpectA comprehensive coil tilter warranty offers protection against manufacturer defects, ensures reliable performance, and minimizes downtime. This article explores what to expect from coil tilter warranties, covering standard coverage, extended warranties, critical component protection, and customer support. Understanding these elem...

-

How Coil tipper Provide Reliable Long-Term Performance: What A coil tipper is a crucial tool in industrial operations, providing safe and efficient handling of heavy coils. This article explores how proper maintenance, key features, and best practices ensure long-term performance and reliability, helping your team maximize productivity and safety in coil handling processes....

-

The Importance of Load Stability in Coil Upenders: Technical This article examines the crucial role of load stability in coil upenders, focusing on the technical aspects that ensure secure and efficient coil handling. It covers key features like clamping systems, automation, and safety measures, and explains how maintaining stability enhances operational efficiency and minimizes risks in i...

-

Coil Flipping Machine vs.Coil Turning EquipmentCoil flipping machines and coil turning equipment play crucial roles in handling and positioning heavy metal coils. This comparison highlights the key differences between the two, focusing on their design, operation, and performance, providing insights to help businesses choose the most suitable solution for their specific needs....

-

How to Evaluate the Efficiency of a Coil Tilting MachineTo evaluate the efficiency of a coil tilting machine, consider its performance in terms of speed, accuracy, and safety. Key aspects include the machine's capacity to handle various coil sizes, its durability, and the level of maintenance required. Energy efficiency and operational reliability are also crucial factors....

-

Motor Shaft UpendersMotor shaft upenders are crucial tools for safely flipping and positioning motor shafts during production or maintenance processes. These machines enhance safety, reduce manual labor, and improve workflow efficiency. Key considerations include their ability to handle varying shaft sizes, rotation precision, and ease of integratio...

-

Worker Fatigue and Safety: The Need for Automated Coil TurninThis article delves into the growing need for automated coil turning equipment to address worker fatigue and safety concerns. By reducing manual handling, automation minimizes physical strain, lowers accident risks, and boosts productivity. Learn how adopting this technology can enhance both employee well-being and operational ef...

-

How Coil Upenders Mitigate the Risk of Coil Damage During TraCoil upenders play a vital role in reducing coil damage during transport by safely flipping and repositioning coils, ensuring load stability, and minimizing human error. This article explores how these machines streamline handling processes, improve safety, and protect coils from costly damage throughout their journey....

-

Weight Capacity and Speed: Understanding Coil Upender PerformWeight capacity and speed are critical performance metrics for coil upenders, directly influencing efficiency, safety, and overall operational success. This article explores how understanding these factors can help industries optimize their coil handling processes, making the right equipment choice for maximizing productivity whi...

-

Coil Upender Manufacturer | Chinese upender machinesChinese coil upender manufacturers provide cost-effective, high-performance machines designed for safe and efficient coil handling. These upenders offer solutions for various industries, ensuring smooth coil rotation and positioning. With a focus on durability, precision, and affordability, Chinese upender machines are ideal for ...

-

Maintenance Requirements for Coil Upenders: What You Need to Proper maintenance of coil upenders is crucial for ensuring efficiency, safety, and extended equipment life. This article covers key maintenance practices, including daily, weekly, and long-term tasks, to help you avoid breakdowns, reduce downtime, and maintain smooth operations in your industrial processes....

-

Industrial Hydraulic TippersIndustrial hydraulic tippers provide a reliable solution for lifting and tipping heavy materials in various industries, including agriculture, construction, and manufacturing. Using hydraulic systems, these tippers enhance efficiency by simplifying the unloading process, reducing the need for manual labor, and improving overall s...

-

Solar Panel UpenderSolar Panel Under offers cutting-edge solar energy performance with superior durability. Engineered for both residential and commercial use, it efficiently converts sunlight into clean power, reducing energy costs and carbon footprint. Its sleek design and advanced materials ensure long-lasting operation, making it a smart choice...

-

Hydraulic Die Mold UpenderThe Hydraulic Die Mold Upender is engineered to flip and tilt large, heavy molds with ease, offering improved safety and efficiency in industrial environments. Its hydraulic system ensures smooth, controlled movements, reducing the risk of damage and manual labor, making it an essential tool for mold handling and maintenance task...

-

90-Degree Flipping MachineDiscover the benefits of a 90-degree flipping machine for heavy industry. Ideal for metallurgy, steel coils, wire reels, and more, this essential equipment ensures safe, efficient flipping of bulky materials, reducing manual labor and improving workflow integration. Maximize safety, streamline operations, and protect your goods w...

-

Injection mold turning machineThe injection mold turning machine offers efficient mold rotation, simplifying mold handling processes and reducing labor intensity. Designed for safety and durability, it prevents mold damage during rotation and accelerates production cycles, making it ideal for manufacturers aiming to improve productivity in injection molding o...

-

Mold Flipping DeviceThe Mold Flipping Device is an industrial solution that efficiently flips and rotates large molds, enhancing production safety and precision. Built to handle substantial weights, it streamlines mold management, reduces manual handling risks, and improves operational workflow, making it invaluable for high-demand manufacturing pro...

-

Bi-Directional Container UpenderA Bi-Directional Container Upender allows seamless rotation of containers in both directions, optimizing material handling and workflow. Built for durability, it enhances workplace safety and efficiency, reducing manual intervention. This versatile equipment is essential for industries focused on improving productivity in heavy-l...

-

Hydraulic Upender for Steel Sheet Loading and Pallet ChangingHydraulic Upender for Steel Sheet Loading and Pallet Changing: The Complete Guide Outline Introduction Overview of hydraulic upenders in industrial applications Importance of hydraulic upenders for steel sheet loading and pallet changing What is a Hydraulic Upender? Definition and basic concept Key components and their functions ...

-

Comprehensive Guide to Upenders and Coil Tippers Features, DeUpenders and coil tippers streamline the handling of bulky, heavy coils by safely rotating and positioning them for further processing or transport. Essential in manufacturing, they improve productivity, reduce labor strain, and enhance workplace safety, making them invaluable for industries that handle large materials like steel...

-

Board turning machine & Board pallet changing machineA board pallet changing system offers two main solutions: an off-line turning machine for flexible, separate handling and an online turning machine for seamless, automated integration. Off-line machines allow precise pallet control, while online machines optimize high-volume operations, enabling efficient, uninterrupted pallet ch...

-

All You Should Know About Coil Upender FailureCoil upender failures can significantly impact productivity and safety. This article delves into the common reasons behind these failures, how to identify warning signs, and practical steps to prevent breakdowns. Gain insights into maintenance practices and solutions to ensure optimal performance and minimize operational disrupti...

A. Upender Platforms and Customization Options

Fhopepack’s mechanical upenders feature a variety of platform designs tailored to accommodate different load types, from flat surfaces to specialized V-saddles that secure cylindrical objects like coils. Here’s a closer look at the options available.

1. Flat Platforms for General Loads

Flat platforms provide a versatile solution for handling square or rectangular loads. These platforms are crafted to maintain stability and provide a secure base for heavy, bulky objects. They are commonly used in applications involving molds, heavy boxes, or large machinery components.

2. V-Saddles for Coil Handling

For industries working with cylindrical items like metal coils, the V-saddle design is indispensable. This specialized platform shape ensures that coils remain stable during the tilting process, reducing the risk of rolling or shifting. Benefits of the V-saddle include:

- Enhanced Load Security: The V-shape cradles the coil securely, preventing movement and potential damage.

- Safe Positioning: The coil’s center of gravity is lowered, allowing for smoother tilting and repositioning.

3. Protective Coverings and Adjustable Platforms

Fhopepack also provides customization options to enhance platform functionality. Protective coverings, for instance, can be added to safeguard delicate surfaces from scratches or abrasions. Additionally, some platforms feature motorized adjustments, allowing operators to modify the platform height or angle for precise load positioning. These customizations make Fhopepack upenders adaptable for unique industrial needs, adding flexibility to an already versatile piece of equipment.

B. Integration with Conveyors and Ball Transfer Rollers

Fhopepack’s mechanical upenders can integrate with other material-handling equipment to improve efficiency, especially in high-volume operations. Conveyor systems and ball transfer rollers are popular options that enable smooth and seamless transitions of loads onto and off the upender.

1. Conveyor Integration for Streamlined Operations

When mechanical upenders are combined with conveyor systems, the entire load-handling process becomes faster and more efficient. Key advantages of conveyor integration include:

- Reduced Manual Intervention: Automation reduces the need for manual lifting, lowering the risk of worker injury.

- Enhanced Workflow Efficiency: Loads can be quickly transferred between stages of production, improving throughput

2. Ball Transfer Rollers for Easy Positioning

Ball transfer rollers provide a flexible method for moving loads in any direction with minimal effort. Installed on the upender platform, they allow operators to position heavy items precisely. This is particularly beneficial in applications where exact alignment is necessary for subsequent stages of handling or processing.

C. Custom Upenders Tailored for Specific Applications

While Fhopepack offers standard models of mechanical upenders, they also specialize in custom designs tailored to meet unique requirements. By collaborating with clients, Fhopepack engineers can design bespoke solutions to accommodate specific load types, environments, and workflows.

1. Specialized Upenders for Industry-Specific Applications

Different industries require specialized handling solutions. Fhopepack can design upenders with additional features like temperature resistance for handling hot items, or enhanced corrosion resistance for environments with high humidity or chemical exposure.

2. Case Study: Customized Upender for the Automotive Industry

In one example, Fhopepack engineered a custom upender for an automotive client requiring precise tilting and positioning of large engine blocks. This upender featured reinforced components and additional safety measures, allowing the client to handle heavy components safely and efficiently, improving productivity on the assembly line.

3. Customizable Controls for Operator Efficiency

Control systems are another area where customization can enhance usability. Fhopepack’s custom upenders can be equipped with user-friendly interfaces, remote controls, or automated settings. These control options allow operators to perform complex maneuvers quickly, reducing the time and effort required to manage large loads.

D. Applications of Mechanical Upenders in Various Industries

Mechanical upenders have versatile applications across a range of industries. Let’s examine how different sectors utilize these machines to improve operational efficiency and safety.

1. Metalworking and Fabrication

In metalworking, large and heavy metal coils, sheets, and components are often handled. Mechanical upenders make it possible to tilt and position these items safely, enhancing workflow efficiency in metal fabrication and welding.

2. Automotive and Aerospace

In the automotive and aerospace industries, mechanical upenders assist in the assembly process, where heavy parts need to be precisely positioned. By using upenders, companies can handle large items like engine blocks and airframe components safely and accurately.

3. Logistics and Warehousing

Mechanical upenders are invaluable in logistics and warehousing, where heavy packages or pallets need to be rotated or repositioned. Upenders allow for quick, safe handling of these loads, which is essential for efficient inventory management and shipping processes.

Standard Features of Fhopepack Mechanical Upenders:

Choosing Fhopepack’s mechanical upenders offers several distinct benefits, from enhanced safety and efficiency to reduced labor costs. Here are some of the key advantages:

-

Increased Safety:

Fhopepack’s upenders minimize the need for manual handling, reducing the risk of injury.

-

Improved Efficiency:

Automated handling improves speed and accuracy, essential for high-volume operations.

-

Cost Savings:

By reducing the need for additional labor, Fhopepack upenders contribute to cost savings over time.

-

Versatility and Customization:

With various customization options, Fhopepack’s upenders cater to a broad range of industrial requirements.

SHOWCASE & NEWS

Product Inquiry

Our team will reply in 24 hours

![]() Email: [email protected]

Email: [email protected]

![]() Whatsapp: 0086-13951501635

Whatsapp: 0086-13951501635