Fhopepack Innovation

Mold Rotator, mould rotating machine

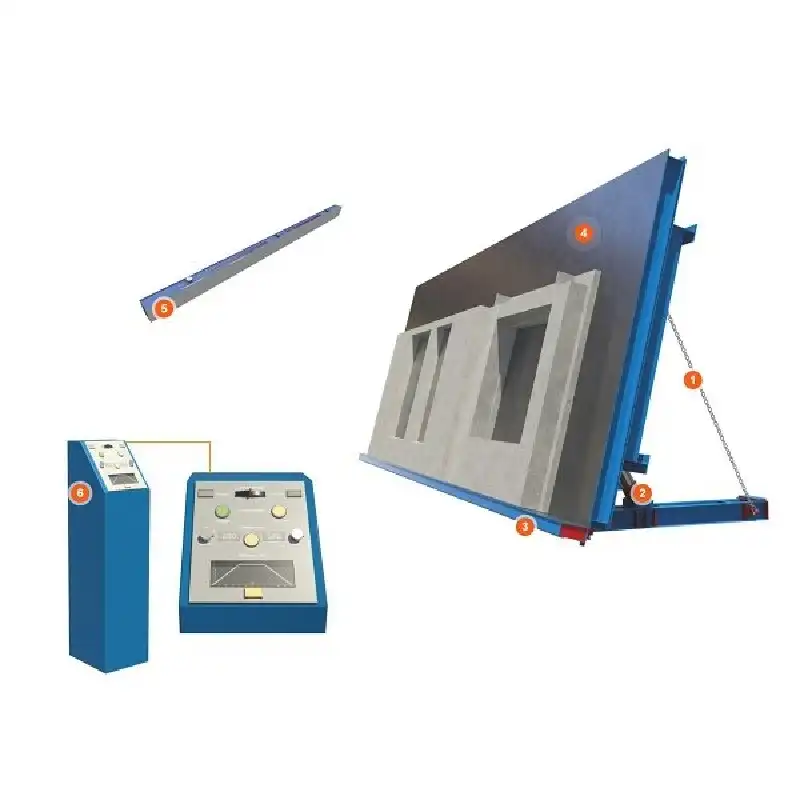

A mold rotator rotates molds controllably for manufacturing processes. It casts, forms or shapes materials into desired shapes by pouring into molds until set.Steady, consistent rotation distributes materials uniformly, resulting in more uniform, consistent finished products. The rotator enables economical production of high-quality goods.Though variably configured, rotators share a purpose: contr