Customizable Features in Coil DownUpender: Tailoring the Machine to Your Needs

Introduction

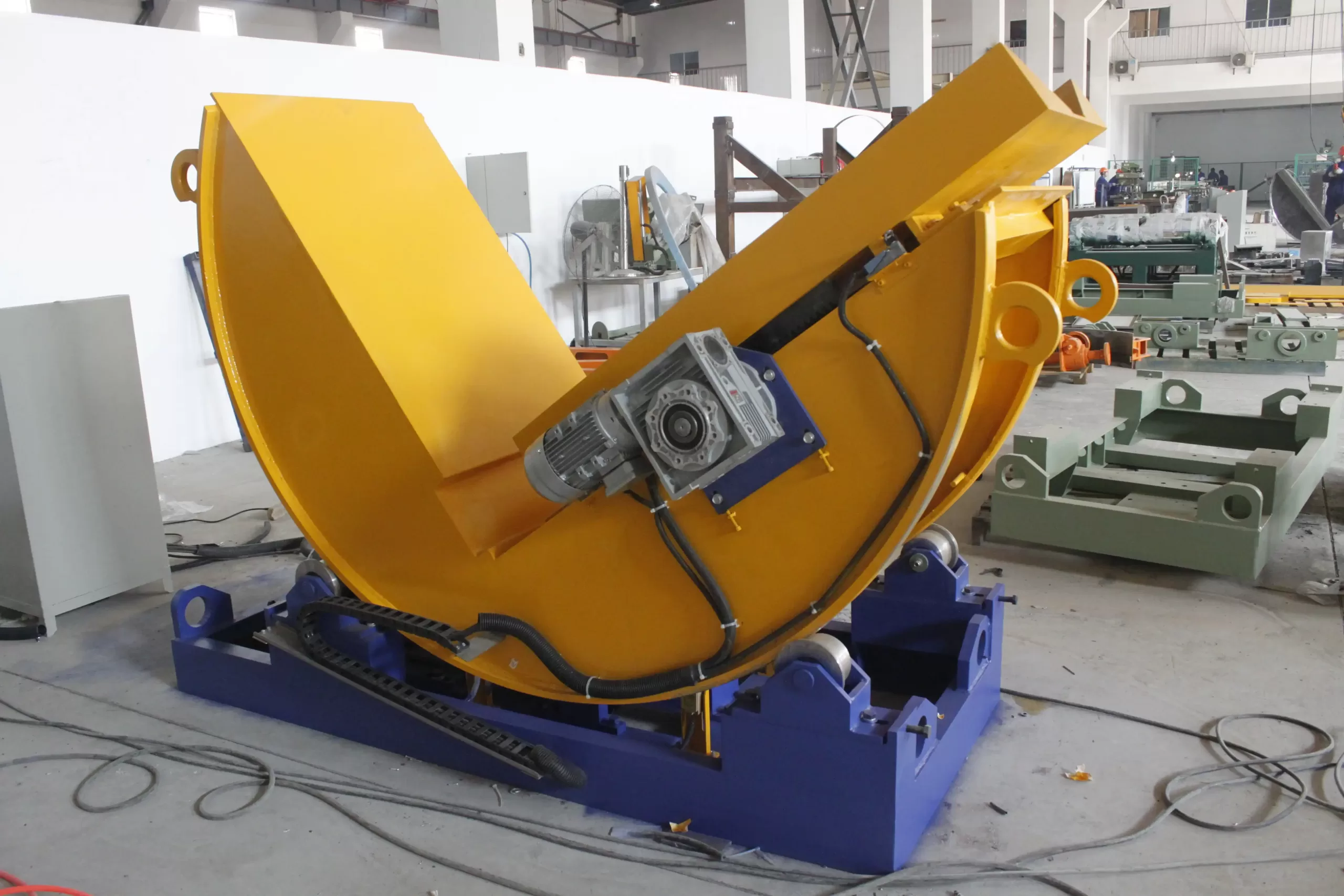

In industrial settings, precision and efficiency are critical factors for success. When dealing with large coils—such as those made of steel, aluminum, or other metals—having the right machinery is essential for handling, rotating, and positioning. One such vital piece of equipment is the

Coil DownUpender, which is designed to assist in rotating heavy coils from horizontal to vertical positions and vice versa. However, not all operations are the same, and having a one-size-fits-all machine may not meet your business's specific needs. That’s where

customizable features come in, allowing you to tailor the machine to suit your operational demands and unique coil handling requirements.

In this article, we will explore the various customizable features available in modern Coil DownUpenders, why they are important, and how they can significantly improve your workflow, safety, and overall operational efficiency. Whether you're in manufacturing, construction, or steel processing, selecting the right custom options can make all the difference.

1. Adjustable Load Capacities for Heavy-Duty Applications

The weight and size of the coils you handle will dictate the load capacity requirements of your Coil DownUpender. Different industries deal with coils of varying materials and sizes—some significantly heavier than others. Adjustable load capacities allow for flexibility, ensuring the machine can handle both lighter and heavier loads without compromising performance or safety.

A customized Coil DownUpender with load capacity options ensures you’re not stuck with a machine that’s either too overpowered for small coils or underpowered for large ones. This feature enables you to strike the right balance, maximizing both machine longevity and operational efficiency. Businesses dealing with steel coils, for instance, may need higher capacity machines, while those handling lighter materials can opt for lower capacities, reducing energy consumption and wear.

2. Variable Speed Control for Precision Handling

When dealing with large and heavy coils, precise control over the machine’s movements is essential. Customizing your Coil DownUpender with variable speed control allows operators to adjust the speed at which the coil is tilted or rotated. This feature ensures the safe and smooth transition of materials, particularly when handling delicate or sensitive coils that could be damaged by abrupt or high-speed movements.

Not only does variable speed control contribute to greater safety, but it also provides an added level of control in complex operations. Operators can choose slower speeds for delicate coils or opt for faster movements when handling more durable materials, increasing overall productivity. This level of flexibility ensures that the machine can adapt to various coil handling scenarios, whether you're performing maintenance, packaging, or repositioning tasks.

3. Customizable Platform Sizes for Versatility

Not all coils are the same size, and a customizable platform on your Coil DownUpender can make the difference between a good fit and a perfect fit. Custom platforms are designed to accommodate a wide range of coil diameters, allowing you to handle everything from smaller coils to large, cumbersome ones with ease. This versatility is essential in industries where the coil size frequently changes based on production demands.

A properly fitted platform not only improves the efficiency of coil handling but also enhances safety by ensuring that the coils are securely positioned during rotation. Customizable platform sizes also reduce the risk of coil slippage or damage, ensuring that every load is properly supported regardless of its size or shape.

4. Safety Features with Customizable Sensors

Safety is a top priority when handling heavy industrial equipment, and a Coil DownUpender is no exception. Modern machines often come equipped with customizable safety sensors that can be tailored to detect potential hazards before they become an issue. These sensors can be adjusted to monitor the weight of the coil, the speed of the tilt, or even the proximity of personnel to the machine during operation.

Customizing your safety features ensures that your machine is equipped to handle the unique challenges of your workspace. For example, in environments where operators work closely with the machine, proximity sensors can halt operations if someone gets too close. Other safety features, such as emergency stop buttons and automatic locking mechanisms, can also be customized to suit your specific safety protocols. This adaptability ensures that safety is not compromised, even in high-risk environments.

5. Integration with Automated Systems

In today's fast-paced industrial world, automation is key to improving productivity and reducing human error. One of the most valuable customizable features available in Coil DownUpenders is their ability to integrate with automated systems. Whether you're running a fully automated facility or just beginning to incorporate automation into your workflow, having a Coil DownUpender that can communicate with other machines is invaluable.

Custom automation options can include programmable logic controllers (PLCs), which allow you to automate the upending process based on specific parameters, such as coil size, weight, or material type. This not only reduces the need for manual intervention but also enhances precision and efficiency. Additionally, you can integrate the machine with robotic arms or automated conveyors, creating a seamless workflow that reduces downtime and maximizes throughput.

6. Tailored Control Panel Interfaces for User-Friendly Operations

Every operator works differently, and having a customized control panel interface can significantly enhance user experience and efficiency. By tailoring the control panel to your operators’ preferences, you can simplify machine operation, reduce errors, and speed up training for new staff.

Customizable features for control panels can include touchscreens with intuitive interfaces, buttons or switches for key functions, and even multi-language support to accommodate diverse workforces. By ensuring that the controls are straightforward and aligned with your specific operational needs, you minimize the risk of operator error and improve overall efficiency. Additionally, these control panels can be designed to be compatible with gloves or other protective equipment, ensuring that the machine can be operated safely in any environment.

7. Adjustable Rotation Angles for Greater Flexibility

Not all coil handling tasks require a full 90-degree rotation. Customizable rotation angles allow you to adjust how far the Coil DownUpender tilts or rotates, giving you greater flexibility in handling coils of different sizes or performing various tasks.

For instance, some applications may only require a 45-degree tilt for repositioning, while others may need a full 180-degree rotation for maintenance or packaging. By customizing the rotation angles, you can ensure that the machine adapts to your exact requirements, reducing the time and effort needed for coil handling. This level of control is particularly beneficial for operations that handle a wide variety of coil sizes and shapes, as it allows you to streamline processes and improve workflow efficiency.

8. Energy-Efficient Customization Options

In today’s environmentally conscious world, energy efficiency is more important than ever. Many manufacturers offer energy-efficient customization options for Coil DownUpenders, allowing you to reduce energy consumption without sacrificing performance. These options might include variable frequency drives (VFDs) that adjust motor speed based on load requirements or energy-saving modes that reduce power consumption during idle periods.

Customizing your machine for energy efficiency not only helps reduce operational costs but also aligns with sustainability goals, an increasingly important factor for many businesses. By tailoring your Coil DownUpender to be more energy-efficient, you can reduce your carbon footprint while maintaining high levels of productivity.

9. Heavy-Duty Construction for Durability and Longevity

Durability is a key consideration when investing in a Coil DownUpender, especially in industries where the machine will be used regularly or in harsh environments. Customizable options for heavy-duty construction ensure that your machine can withstand the demands of your operations.

From reinforced frames to wear-resistant coatings, there are a variety of customization options available to enhance the durability of your machine. You can also opt for upgraded materials like stainless steel or corrosion-resistant alloys, depending on the environment in which the machine will be used. These customizations not only extend the lifespan of the machine but also reduce the need for frequent repairs and maintenance, saving you both time and money in the long run.

10. Modular Design for Future Expansion

One of the most forward-thinking customizable features in a Coil DownUpender is the option for modular design. Modular machines are built with expansion in mind, allowing you to add new features or upgrade existing ones as your business grows. This could include adding new safety features, upgrading control systems, or integrating additional automation options.

By choosing a modular design, you ensure that your Coil DownUpender can evolve with your business. As your operations expand, you won’t need to invest in an entirely new machine—simply add or upgrade the necessary components. This flexibility is invaluable for businesses that expect to scale or diversify their operations over time.

Conclusion

A Coil DownUpender is a crucial piece of equipment for handling heavy, bulky coils efficiently and safely. However, not all operations are the same, and having a customizable machine can make a significant difference in your overall productivity and safety. From adjustable load capacities and variable speed controls to tailored safety features and energy-efficient options, the ability to customize your Coil DownUpender ensures that it meets your unique operational needs.

By investing in a Coil DownUpender with customizable features, you’re not just purchasing a machine—you’re gaining a solution tailored specifically to your workflow, safety requirements, and future growth. This level of customization allows you to maximize efficiency, reduce downtime, and ensure that your operations run smoothly for years to come.