Fhopepack Innovation

Die flipper for mould and die | FHOPE

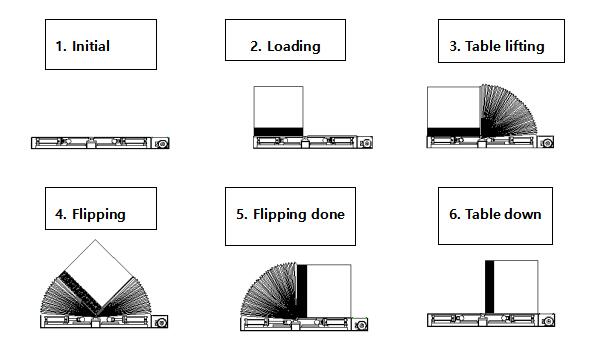

Die flippers invert molds swiftly and surely without damage. Two versions assist in handling and flipping heavy molds up to 60 tons: 180-degree flippers and hydraulic systems. 180-degree flippers flip molds 180 degrees, minimizing contact. Hydraulic systems harness pressurized oil to flip, rotate or tilt molds up to angles for easy access and removal. Equipped telescopically for extra reach or