Top 6 Things to Choose a Customized Hydraulic Coil Upender

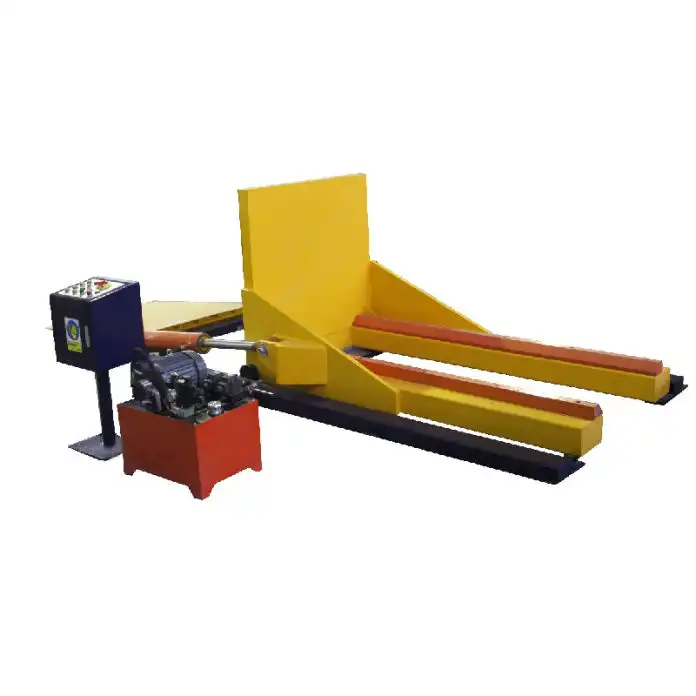

Handling heavy-duty materials like coils in industries such as steel, aluminum, and wire manufacturing is no small feat. The process of tilting and positioning coils can be labor-intensive, time-consuming, and fraught with safety risks. That’s why investing in a hydraulic coil upender can make a huge difference. These machines are designed to rotate or flip coils with ease, enhancing both operational efficiency and safety. However, not all coil upenders are created equal, and customization plays a key role in ensuring the machine meets your specific needs.

In this article, we’ll explore the top six factors you should consider when selecting a customized hydraulic coil upender. By the end, you’ll have a clear understanding of how to make an informed choice that aligns with your production goals and improves your workflow.

1. Load Capacity: Ensuring the Machine Can Handle Your Coils

The first and most critical factor to consider when choosing a customized hydraulic coil upender is the load capacity. This refers to the maximum weight that the machine can safely handle without compromising performance. Coil weights can vary greatly depending on the material and size, so it’s essential to ensure that your upender can support the specific loads in your operation.

For example, steel coils are typically heavier than aluminum or copper coils, and selecting an upender with an insufficient load capacity can lead to breakdowns or, worse, safety hazards. When customizing a coil upender, you should have the option to choose a model that matches your heaviest coil loads, ensuring seamless operation.

Tip: Always account for your heaviest coil and add some buffer for potential future increases in load weight. This will future-proof your investment and ensure long-term reliability.

2. Rotation Speed and Control: Balancing Efficiency and Precision

The rotation speed of a coil upender is another crucial element to consider. Different production environments have varying needs when it comes to the speed of flipping coils. Some industries may prioritize high-speed operations to maximize throughput, while others may require precision control to avoid damaging sensitive materials.

A customized hydraulic coil upender should allow you to adjust the speed to match your production pace. For delicate materials, slow and controlled flipping is ideal to prevent damage. On the other hand, if your operation deals with tough, durable coils, faster rotation might be more beneficial to keep up with demand.

Additionally, look for machines that offer customizable controls such as variable speed settings and automated stop mechanisms. This allows operators to have full control over the flipping process, enhancing both efficiency and product protection.

3. Space Considerations: Tailoring the Size to Your Facility

Not all production facilities have the same amount of space available for machinery. Before investing in a hydraulic coil upender, it’s vital to consider the physical space in which the machine will operate. Customizing the size and design of the upender ensures that it fits seamlessly into your existing production line without causing any disruptions.

A compact upender is ideal for smaller facilities, where floor space is limited, but it should still have the necessary power to handle your coils. For larger production lines, you may opt for a more robust machine with advanced features, such as automated coil handling or integrated safety mechanisms.

Some manufacturers offer space-saving designs that allow for efficient operation in tight spaces, ensuring that your investment doesn’t compromise your production layout. Make sure to measure your available space and consider potential future expansions when selecting the size and dimensions of your coil upender.

4. Customizable Safety Features: Protecting Workers and Materials in Real-World Operation

In industrial environments, especially in heavy-duty operations like coil handling, safety is paramount. A hydraulic coil upender equipped with customizable safety features can significantly mitigate risks associated with both human errors and material mishandling. The technical design and operational scenarios of a coil upender require well-thought-out safety mechanisms to ensure the smooth and secure flipping of coils, while safeguarding the workers who operate and work around the machine.

In real-world applications, the complexity of coil handling—whether dealing with steel, aluminum, or wire coils—can expose operators to potential hazards, such as coil instability or machine malfunctions. Therefore, choosing a hydraulic coil upender with customizable safety features is essential for preventing accidents and material damage.

Key customizable safety features include:

-

Emergency Stop Buttons: A must-have in any coil handling scenario, these buttons allow operators to immediately halt the machine’s operation if they detect any issues, such as coil misalignment or mechanical failure. Strategically placed on both the control panel and around the machine, these buttons ensure that operators can act swiftly in emergencies, minimizing the risk of injury or damage.

-

Load Sensors for Coil Stability: As the machine flips and rotates heavy coils, load sensors continuously monitor the balance and weight distribution. These sensors are crucial in preventing dangerous tilting or uneven flipping, automatically adjusting the process if an imbalance is detected. In situations where the coil may shift or be improperly loaded, the sensors halt the machine, ensuring the coil is stabilized before continuing. This feature is particularly beneficial in high-speed operations, where precision handling is vital to avoid accidents.

-

Guardrails and Barriers for Operator Protection: Given that coil upenders deal with massive loads, the installation of guardrails and physical barriers around the operational area is a critical safety feature. These barriers prevent workers from accidentally stepping into dangerous zones during operation, especially when handling extremely heavy or fast-moving coils. With customizable safety zones, you can design the barriers to fit specific factory layouts, ensuring workers remain protected while allowing for efficient machine operation.

-

Automated Locking Mechanisms: During the flipping or tilting process, the risk of coil movement is a major safety concern. Customizable locking mechanisms ensure that the coil is securely fastened in place, both during and after the rotation process. These locks prevent any unwanted movement that could cause the coil to slip or fall, particularly during stops or load transitions. Whether dealing with fragile materials or heavy-duty coils, this feature guarantees the coil’s stability throughout the entire handling process.

5. Ease of Integration with Your Existing System

An effective hydraulic coil upender should integrate seamlessly with your existing production line. It’s important to ensure that the upender you choose is compatible with your other machinery, whether it's a coil handling system, crane, or conveyor belt. Smooth integration minimizes disruptions and ensures that your workflow remains efficient.

Customization options should include:

-

Compatibility with automation systems: If your facility uses automated coil handling or storage systems, your coil upender must be able to sync with them for seamless operation.

-

Control panel customization: Many manufacturers allow you to customize the control panels of upenders, ensuring that they are intuitive for your operators and compatible with the systems they already use.

-

Data and software integration: Some modern upenders come equipped with data collection features that can integrate into your ERP systems, helping you track productivity and maintenance needs.

Customizing these elements ensures that your new coil upender works as part of a cohesive system, rather than as a standalone machine. This streamlined integration maximizes efficiency and reduces the learning curve for operators.

6. Maintenance and Serviceability: Ensuring Long-Term Reliability

No matter how advanced or well-built a coil upender is, regular maintenance is essential for keeping it running smoothly. When customizing your hydraulic coil upender, it’s important to consider the ease of maintenance and serviceability.

Here are a few key aspects to consider:

-

Accessibility of components: A well-designed upender should allow easy access to critical components for maintenance tasks such as oil changes, part replacements, and inspections.

-

Maintenance support: Customizable upenders should come with detailed maintenance schedules and guidelines, ensuring that your team knows exactly what to do to keep the machine in optimal condition.

-

Availability of spare parts: Ensure that the manufacturer provides easy access to spare parts or offers customizable part replacement packages for wear-prone components. This minimizes downtime in the event of a breakdown.

By customizing your upender to include maintenance-friendly features, you can extend the lifespan of your machine, reduce downtime, and ensure long-term reliability. Furthermore, regular maintenance helps maintain safety and performance standards, ensuring that your upender remains a valuable asset to your operation for years to come.

Conclusion: Investing in the Right Customized Hydraulic Coil Upender

Choosing the right customized hydraulic coil upender requires careful consideration of several factors. From load capacity and rotation speed to safety features and maintenance, each aspect plays a role in determining how well the upender fits into your unique production environment.

By focusing on customization, you can ensure that your coil upender meets all of your specific needs, from handling your heaviest coils to integrating seamlessly with your existing systems. Investing in a customized coil upender not only boosts efficiency and safety but also ensures long-term reliability and reduced downtime. For businesses that handle large, heavy coils, a customized hydraulic coil upender is a smart investment that can significantly improve productivity and operational flow.

When making your choice, prioritize the features that are most important for your workflow and future-proof your investment by considering potential changes in production requirements. Ultimately, the right coil upender will become an invaluable tool, delivering both short-term efficiency gains and long-term operational success.