Hydraulic Upender for Steel Sheet Loading and Pallet Changing: The Complete Guide

Introduction

In industries that handle large, heavy steel sheets, efficient material handling is essential for productivity and safety. A hydraulic upender, designed specifically for steel sheet loading and pallet changing, is an innovative solution that simplifies these processes, reducing manual labor and potential hazards. These upenders allow operators to effortlessly tilt or rotate steel sheets, making it easier to load, align, and reposition materials without risk of injury or downtime. This guide delves into the various aspects of hydraulic upenders, offering insights into their features, benefits, and importance in steel handling.

What is a Hydraulic Upender?

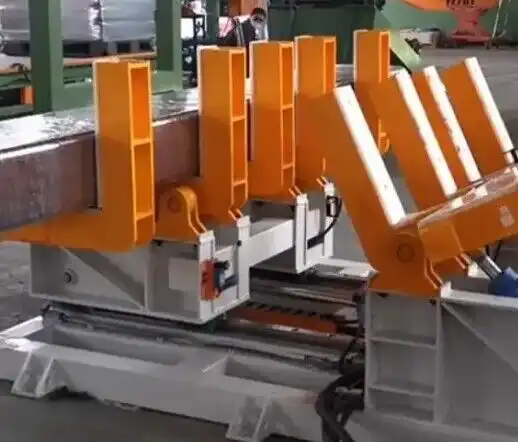

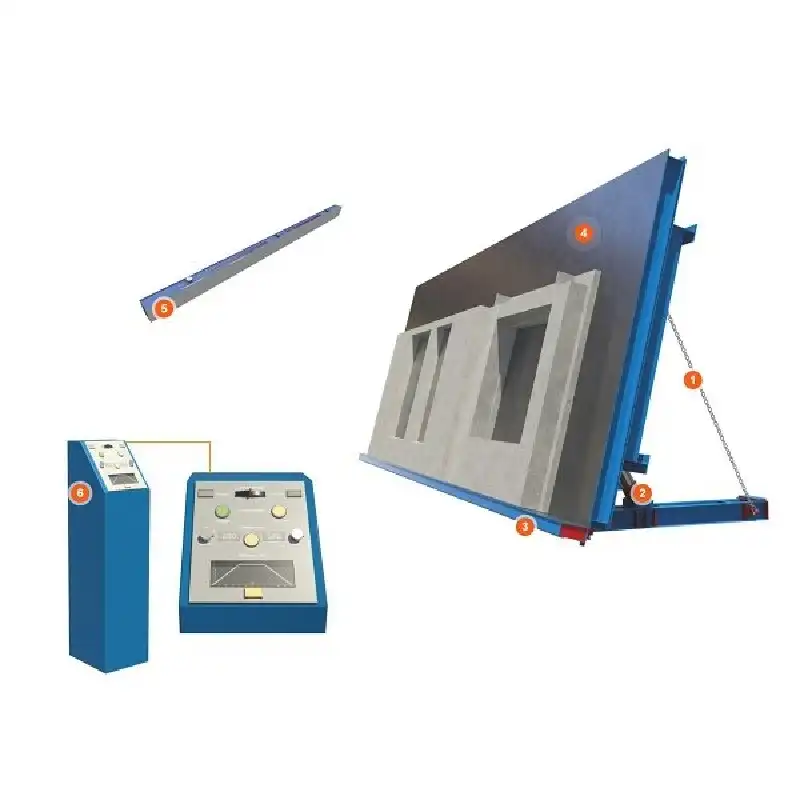

A hydraulic upender is a specialized piece of equipment used to tilt, turn, or flip heavy materials, such as steel sheets, into a position optimal for processing. Equipped with hydraulic power, these machines use controlled pressure to perform smooth, precise movements. Common components of a hydraulic upender include a base platform, a rotating mechanism, hydraulic cylinders, and a control system that manages the machine’s operation. Each part plays a role in creating a balanced, powerful upending system that is reliable and easy to operate.

Applications of Hydraulic Upenders in Steel Sheet Handling

Hydraulic upenders are indispensable in metalworking, automotive, shipbuilding, and other sectors where steel sheets are manipulated and processed. In these industries, steel sheets need to be loaded, aligned, cut, or modified. The hydraulic upender assists in flipping or rotating these sheets from horizontal to vertical positions, ensuring the material is in the correct orientation for each production step. In essence, it eliminates the manual handling of heavy steel sheets, improving speed and efficiency.

How Hydraulic Upenders Aid in Pallet Changing

Pallet changing is another crucial step in steel sheet handling. A hydraulic upender makes it possible to switch pallets seamlessly without disrupting workflow. When steel sheets are placed on different pallets for specific processes, the upender aids in lifting and rotating them, allowing operators to change pallets quickly and without risk. This capability is particularly valuable in high-volume facilities where every second counts.

Key Features of a Hydraulic Upender for Steel Sheets

-

Weight Capacity: Designed to handle significant loads, most hydraulic upenders can accommodate steel sheets weighing thousands of pounds.

-

Rotation and Tilt Angles: Upenders can often tilt up to 90 or 180 degrees, making them versatile for different material orientations.

-

Precision Controls: Equipped with advanced controls, many hydraulic upenders offer precision adjustments for safe and efficient operation, including features like foot pedals or remote control options.

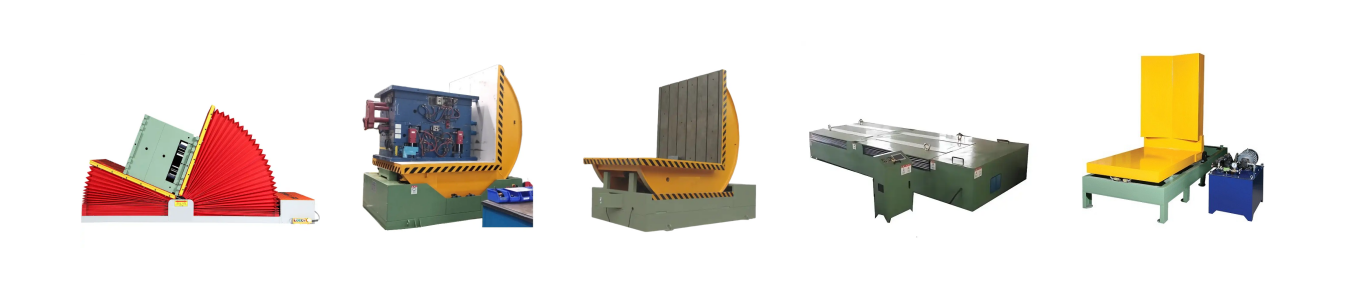

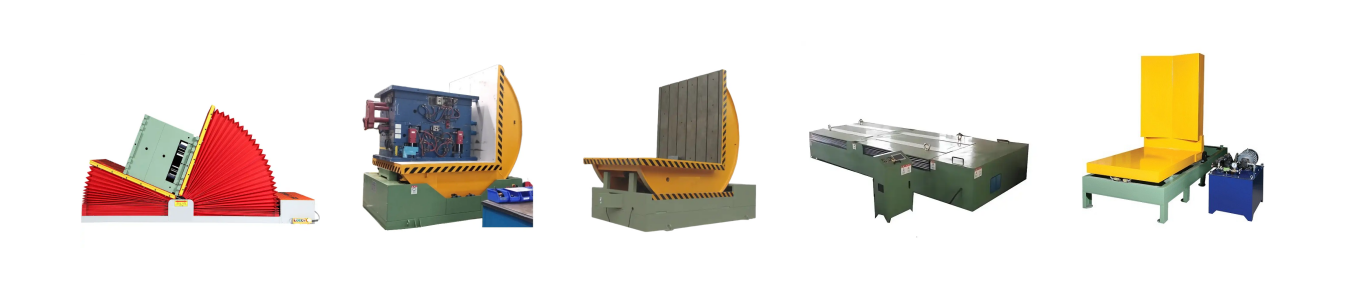

Types of Hydraulic Upenders for Steel Sheet Loading

Hydraulic upenders come in different types, catering to various operational needs:

-

Stationary Hydraulic Upenders: These are fixed at one location and are best suited for facilities where steel sheets are handled in a centralized area.

-

Mobile Hydraulic Upenders: Mounted on wheels or casters, these upenders provide flexibility, allowing operators to move them to different locations as needed.

-

Custom Hydraulic Upenders: Designed for specific requirements, custom upenders can include features tailored to unique industrial applications, offering greater flexibility in operations.

Safety Features in Hydraulic Upenders

Safety is a primary concern when handling heavy steel sheets. Hydraulic upenders come with various safety features, including:

-

Safety Locks and Sensors: To ensure stability and avoid accidental movement.

-

Emergency Stop Buttons: Immediate shutdown options for emergencies.

-

Load-Sensing Capabilities: Alerts operators to potential overloading, preventing damage to the machine and reducing the risk of accidents.

Benefits of Using a Hydraulic Upender for Steel Sheets

The advantages of hydraulic upenders go beyond mere convenience:

-

Enhanced Productivity: With automation and hydraulic power, upenders significantly speed up loading, unloading, and pallet changes.

-

Improved Safety: By reducing the need for manual handling, upenders minimize the risk of injuries associated with lifting and tilting heavy sheets.

-

Reduced Manual Labor: Operators no longer have to bear the physical burden, making the workplace more ergonomic and productive.

Choosing the Right Hydraulic Upender for Your Needs

When selecting a hydraulic upender, certain factors play a critical role:

-

Load Capacity: Ensure the upender can handle the weight of your steel sheets and any additional equipment or pallets.

-

Mobility: Determine if a stationary or mobile upender fits your workflow better.

-

Reliability: Choose a reliable vendor offering strong customer support, as this equipment requires regular maintenance for optimal performance.

Installation of a Hydraulic Upender for Steel Sheet Loading

Proper installation is vital for maximizing the performance and lifespan of a hydraulic upender. Here are some steps involved:

-

Site Preparation: Clear the installation area, ensuring it is level and spacious enough to allow safe operation.

-

Mounting the Upender: Securely mount the upender on a stable foundation to prevent movement.

-

Testing: Test all hydraulic and control systems for proper function before commencing operations.

Maintenance and Care of Hydraulic Upenders

Maintaining a hydraulic upender prolongs its operational life and ensures safety. Basic maintenance includes:

-

Routine Checks: Inspect hydraulic hoses, cylinders, and joints regularly to detect any wear and tear.

-

Lubrication: Keep moving parts well-lubricated to prevent friction-related damage.

-

Troubleshooting Common Issues: Address any abnormal sounds or sluggish movements immediately, as these can indicate issues with the hydraulic system or components.

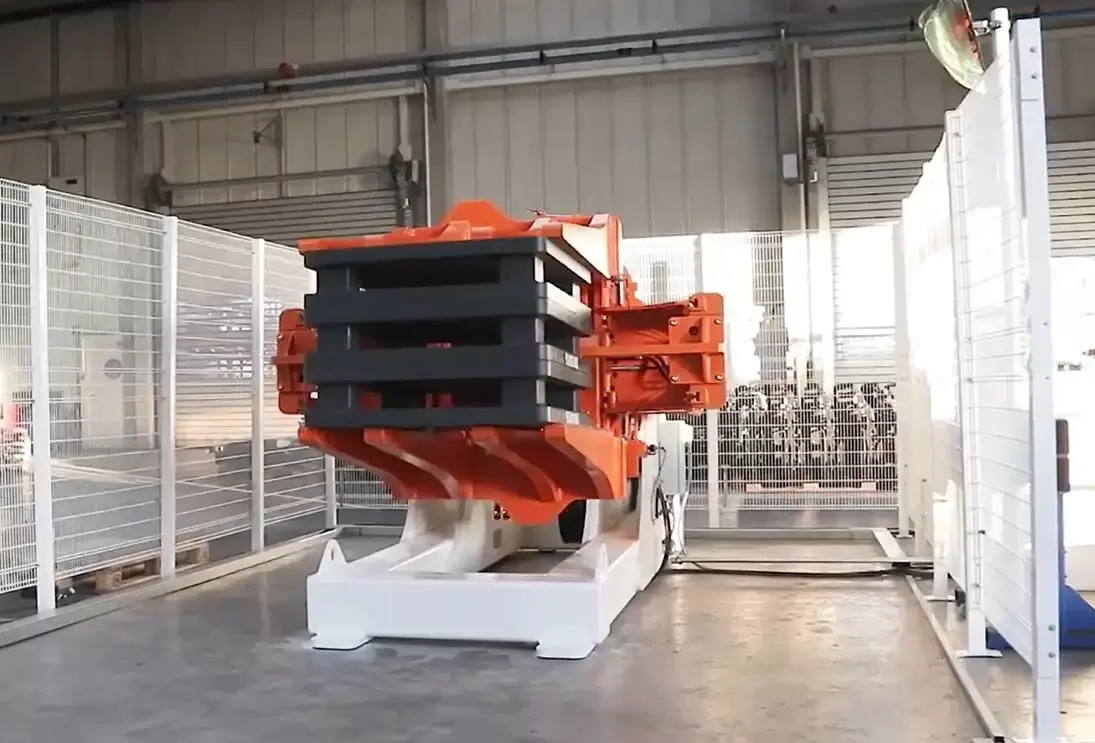

The Role of Hydraulic Upenders in Automated Workflows

In modern manufacturing, hydraulic upenders are integral to automated workflows. When integrated with robots or automated material handling systems, they offer unmatched efficiency, allowing for continuous, uninterrupted operations with minimal human intervention.

Comparing Hydraulic Upenders with Other Material Handling Equipment

While other equipment like forklifts and cranes can also manage heavy loads, hydraulic upenders provide specific advantages for steel sheet handling:

-

Precision in Positioning: Upenders are designed for controlled tilting and rotation, ideal for precise loading tasks.

-

Stability: They offer unmatched stability when tilting heavy steel sheets, reducing the likelihood of accidents.

Cost Considerations for Hydraulic Upenders

Investing in a hydraulic upender can yield significant productivity and safety benefits, often justifying the initial cost. While prices vary widely—ranging from $10,000 for standard models to over $100,000 for customized, heavy-duty units—the return on investment (ROI) can be swift, particularly in high-volume applications. By reducing manual handling, upenders lower injury risks and improve operational efficiency, leading to savings on labor and downtime.

Businesses should consider financing or leasing options offered by many suppliers, which can ease upfront expenses and spread costs over time. Additionally, customization may increase the initial price but can enhance long-term efficiency by precisely meeting operational needs. Regular maintenance, though an added cost, prolongs equipment lifespan and prevents costly repairs.

Ultimately, hydraulic upenders not only boost productivity but also foster a safer work environment, reducing injury-related costs and improving worker satisfaction. For businesses with heavy material handling requirements, the investment is often recouped through enhanced efficiency and reduced operational risks.

Case Studies: Real-Life Examples of Hydraulic Upender Applications

-

High-Volume Steel Fabrication Plant: In a high-volume steel fabrication plant, productivity and worker safety are paramount due to the extensive number of heavy materials processed daily. By implementing hydraulic upenders, this large facility was able to transform its workflow, handling thousands of steel sheets per day with increased speed and accuracy. The upenders enabled quick flipping and positioning of each sheet, allowing the material to seamlessly transition from one production phase to the next, such as from cutting to shaping or from stacking to transport. This automation of material rotation not only streamlined operations but also significantly reduced the physical strain on workers, who would otherwise need to handle heavy steel manually, often using multiple team members or complex lifting equipment. The hydraulic upender's precision in rotating and aligning each sheet reduced errors in alignment and positioning, ensuring quality control while enhancing the plant’s overall productivity. This increase in efficiency allowed the plant to meet higher production targets, optimize labor distribution, and ultimately improve its output without the need for extensive additional manpower.

-

Custom Pallet-Changing Setup: For a specialized metalworking facility handling oversized steel sheets, traditional upenders weren’t sufficient to meet the unique demands of their operations. The facility required custom-designed hydraulic upenders tailored to handle larger-than-average sheet dimensions, which could pose significant challenges in rotation, alignment, and pallet placement. By investing in custom upenders, the facility was able to integrate a precise pallet-changing setup specifically suited to their material requirements. This setup allowed for smooth, controlled rotations and seamless transitions between different stages of material handling, including loading, flipping, and pallet positioning. Custom hydraulic upenders provided the strength and precision needed to handle these large sheets without damaging them or misaligning pallets, resulting in operational improvements across the board. With the enhanced setup, the facility saw faster turnover times, reduced handling errors, and less equipment wear, ultimately leading to increased operational efficiency, improved safety standards, and reduced costs associated with downtime and maintenance. This tailored approach demonstrated the value of customizing machinery to fit specific operational needs, yielding significant benefits in productivity and workflow consistency.

Future of Hydraulic Upenders in Steel Handling and Pallet Changing

With advances in hydraulic technology and automation, hydraulic upenders are expected to become even more efficient and versatile. Integration with Industry 4.0 technologies will enable real-time monitoring and predictive maintenance, further enhancing their value in steel handling applications.

Conclusion

A hydraulic upender is a vital tool for facilities that manage heavy steel sheets and require frequent pallet changes. By simplifying the process and increasing safety, these machines help businesses improve productivity and reduce risks, making them a worthwhile investment for any heavy-duty handling environment.

FAQs

-

What is the average cost of a hydraulic upender?

-

Costs vary depending on size, capacity, and customization, but basic models can start at around $10,000, with high-capacity models costing more.

-

Can hydraulic upenders handle irregularly shaped steel sheets?

-

Yes, many hydraulic upenders can be customized or adjusted to accommodate irregularly shaped materials.

-

How do I maintain my hydraulic upender for peak performance?

-

Regularly inspect hydraulic components, keep parts lubricated, and perform any necessary repairs promptly to ensure optimal function.

-

Are there specific certifications for operating a hydraulic upender?

-

While requirements vary by location, operators may need training in material handling safety and equipment-specific training for upender use.

-

How does a hydraulic upender fit into automated material handling systems?

-

Hydraulic upenders can be integrated with automation software and robotic systems, enabling seamless operation and reducing the need for manual intervention.