Comprehensive Guide to Upenders and Coil Tippers Features, Designs, and Customization

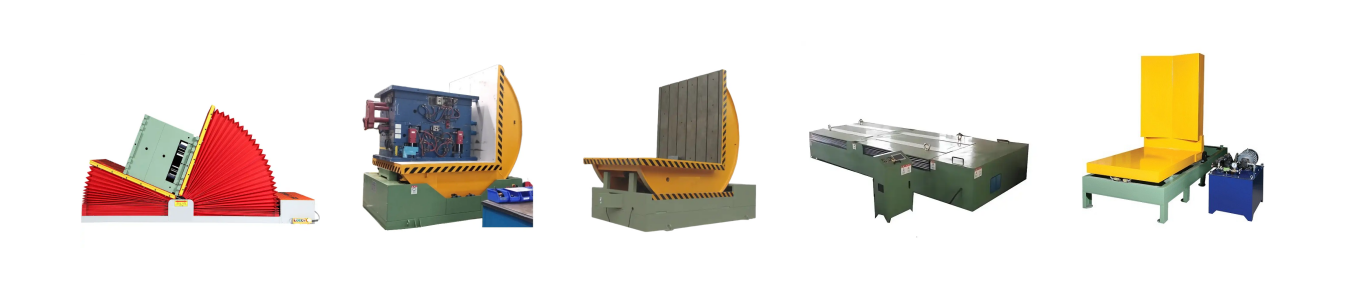

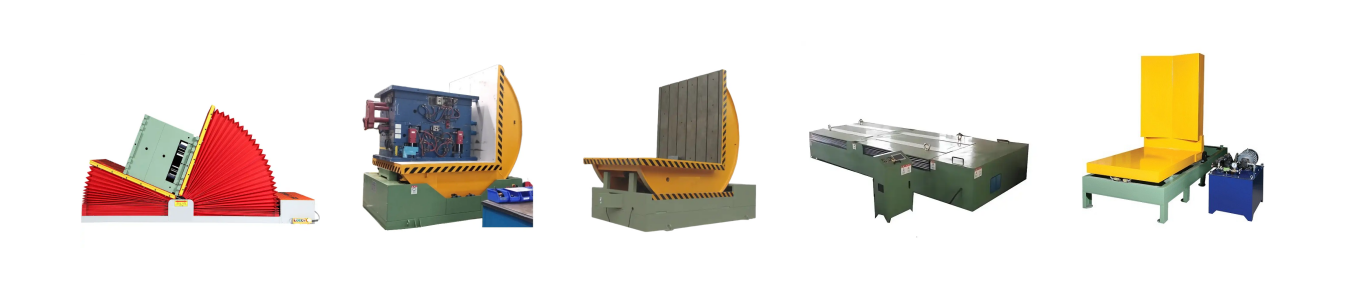

Introduction to Mechanical Upenders and Coil Tippers

In industries dealing with large, heavy loads like metal coils, molds, and dies, effective handling solutions are essential. Mechanical upenders and coil tippers, such as those offered by Fhopepack, play a vital role in facilitating safe, efficient handling and positioning of these hefty items. Designed for durability and reliability, these machines cater to industries that regularly maneuver cumbersome, heavy loads, reducing risks associated with manual handling. This article explores the key features, design options, and applications of Fhopepack’s mechanical upenders, offering insights into how they can be customized to suit specific industrial needs.

Standard Features of Fhopepack Mechanical Upenders

Mechanical upenders come with several essential features that make them indispensable in heavy-load handling. These features reflect the robustness and versatility of Fhopepack’s designs, ensuring safe and effective handling of items across various weights and sizes.

1. Load Capacities Ranging from 3,000 to 100,000 Pounds

Fhopepack’s mechanical upenders are designed to handle loads of varying sizes and weights, with capacities ranging from 3,000 pounds for lighter applications to an impressive 100,000 pounds for extremely heavy loads. This wide range of capacity options makes these machines suitable for diverse applications across industries, from automotive and aerospace to metalworking and logistics.

2. Robust Welded Steel Construction

The foundation of any mechanical upender’s durability is its construction. Fhopepack employs robust welded steel for the mainframe of their upenders, ensuring that they can endure the stresses and demands of heavy-duty industrial applications. This type of construction offers:

-

Enhanced Stability: The solid steel construction helps maintain balance and reduce vibrations during operation.

-

Long-Term Durability: Welded joints add strength to the frame, minimizing the chances of structural wear over time.

-

Minimal Maintenance: The robust structure requires less frequent maintenance, reducing downtime in busy industrial environments.

3. Safety Features and Compliance Standards

Safety is a primary concern in handling equipment. Fhopepack’s upenders are equipped with safety features like emergency stop buttons, safety covers, and warning indicators. These additions ensure that operations are not only efficient but also safe for operators, aligning with industrial safety standards and regulatory requirements.

Upender Platforms and Customization Options

Fhopepack’s mechanical upenders feature a variety of platform designs tailored to accommodate different load types, from flat surfaces to specialized V-saddles that secure cylindrical objects like coils. Here’s a closer look at the options available.

1. Flat Platforms for General Loads

Flat platforms provide a versatile solution for handling square or rectangular loads. These platforms are crafted to maintain stability and provide a secure base for heavy, bulky objects. They are commonly used in applications involving molds, heavy boxes, or large machinery components.

2. V-Saddles for Coil Handling

For industries working with cylindrical items like metal coils, the V-saddle design is indispensable. This specialized platform shape ensures that coils remain stable during the tilting process, reducing the risk of rolling or shifting. Benefits of the V-saddle include:

-

Enhanced Load Security: The V-shape cradles the coil securely, preventing movement and potential damage.

-

Safe Positioning: The coil’s center of gravity is lowered, allowing for smoother tilting and repositioning.

3. Protective Coverings and Adjustable Platforms

Fhopepack also provides customization options to enhance platform functionality. Protective coverings, for instance, can be added to safeguard delicate surfaces from scratches or abrasions. Additionally, some platforms feature motorized adjustments, allowing operators to modify the platform height or angle for precise load positioning. These customizations make Fhopepack upenders adaptable for unique industrial needs, adding flexibility to an already versatile piece of equipment.

Integration with Conveyors and Ball Transfer Rollers

Fhopepack’s mechanical upenders can integrate with other material-handling equipment to improve efficiency, especially in high-volume operations. Conveyor systems and ball transfer rollers are popular options that enable smooth and seamless transitions of loads onto and off the upender.

1. Conveyor Integration for Streamlined Operations

When mechanical upenders are combined with conveyor systems, the entire load-handling process becomes faster and more efficient. Key advantages of conveyor integration include:

-

Reduced Manual Intervention: Automation reduces the need for manual lifting, lowering the risk of worker injury.

-

Enhanced Workflow Efficiency: Loads can be quickly transferred between stages of production, improving throughput.

2. Ball Transfer Rollers for Easy Positioning

Ball transfer rollers provide a flexible method for moving loads in any direction with minimal effort. Installed on the upender platform, they allow operators to position heavy items precisely. This is particularly beneficial in applications where exact alignment is necessary for subsequent stages of handling or processing.

Custom Upenders Tailored for Specific Applications

While Fhopepack offers standard models of mechanical upenders, they also specialize in custom designs tailored to meet unique requirements. By collaborating with clients, Fhopepack engineers can design bespoke solutions to accommodate specific load types, environments, and workflows.

1. Specialized Upenders for Industry-Specific Applications

Different industries require specialized handling solutions. Fhopepack can design upenders with additional features like temperature resistance for handling hot items, or enhanced corrosion resistance for environments with high humidity or chemical exposure.

2. Case Study: Customized Upender for the Automotive Industry

In one example, Fhopepack engineered a custom upender for an automotive client requiring precise tilting and positioning of large engine blocks. This upender featured reinforced components and additional safety measures, allowing the client to handle heavy components safely and efficiently, improving productivity on the assembly line.

3. Customizable Controls for Operator Efficiency

Control systems are another area where customization can enhance usability. Fhopepack’s custom upenders can be equipped with user-friendly interfaces, remote controls, or automated settings. These control options allow operators to perform complex maneuvers quickly, reducing the time and effort required to manage large loads.

Applications of Mechanical Upenders in Various Industries

Mechanical upenders have versatile applications across a range of industries. Let’s examine how different sectors utilize these machines to improve operational efficiency and safety.

1. Metalworking and Fabrication

In metalworking, large and heavy metal coils, sheets, and components are often handled. Mechanical upenders make it possible to tilt and position these items safely, enhancing workflow efficiency in metal fabrication and welding.

2. Automotive and Aerospace

In the automotive and aerospace industries, mechanical upenders assist in the assembly process, where heavy parts need to be precisely positioned. By using upenders, companies can handle large items like engine blocks and airframe components safely and accurately.

3. Logistics and Warehousing

Mechanical upenders are invaluable in logistics and warehousing, where heavy packages or pallets need to be rotated or repositioned. Upenders allow for quick, safe handling of these loads, which is essential for efficient inventory management and shipping processes.

Advantages of Using Fhopepack Mechanical Upenders

Choosing Fhopepack’s mechanical upenders offers several distinct benefits, from enhanced safety and efficiency to reduced labor costs. Here are some of the key advantages:

-

Increased Safety: Fhopepack’s upenders minimize the need for manual handling, reducing the risk of injury.

-

Improved Efficiency: Automated handling improves speed and accuracy, essential for high-volume operations.

-

Cost Savings: By reducing the need for additional labor, Fhopepack upenders contribute to cost savings over time.

-

Versatility and Customization: With various customization options, Fhopepack’s upenders cater to a broad range of industrial requirements.

Conclusion

Fhopepack’s mechanical upenders and coil tippers are essential tools for industries requiring heavy-load handling solutions. From robust construction and versatile platform options to custom designs tailored for specific applications, these upenders offer the flexibility, safety, and efficiency that modern industries demand. By integrating Fhopepack upenders into their workflow, companies can enhance productivity and protect workers, making them a valuable investment for any operation handling heavy or bulky loads.

FAQs

1. What industries benefit most from using mechanical upenders?

Industries like metalworking, automotive, aerospace, and logistics benefit greatly from mechanical upenders, as they handle heavy, cumbersome items that need safe and efficient repositioning.

2. Can Fhopepack upenders handle non-metal materials?

Yes, Fhopepack upenders can be customized to handle a variety of materials, including plastic, wood, and other composites, depending on the industry’s needs.

3. Are there specific safety certifications for Fhopepack’s upenders?

Fhopepack ensures that their upenders comply with industry safety standards and can incorporate additional safety features based on customer requirements.

4. What load capacities do Fhopepack’s upenders support?

Their upenders range from capacities of 3,000 to 100,000 pounds, accommodating diverse load sizes for various applications.

5. How does Fhopepack ensure upender durability?

Through welded steel construction and rigorous quality control, Fhopepack’s upenders are designed for long-term durability, even in demanding industrial environments.