The Importance of Load Stability in Coil Upenders: Technical Breakdown

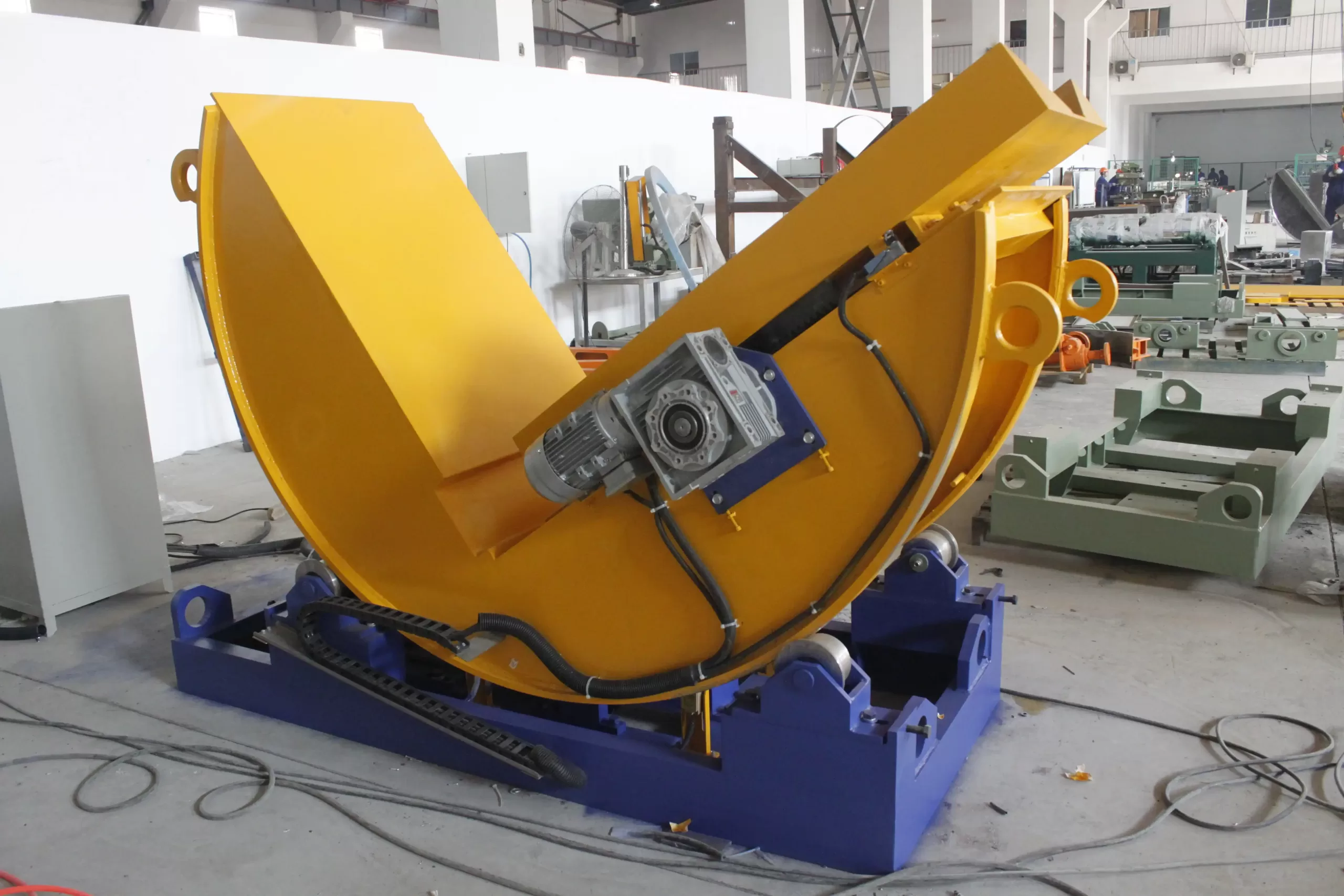

Coil upenders play a crucial role in many industries, particularly those dealing with heavy, cumbersome coils such as steel, aluminum, or copper. These machines are specifically designed to rotate large coils from a horizontal to a vertical position, or vice versa, allowing for efficient handling and processing. While coil upenders themselves offer remarkable benefits in terms of productivity and safety, one often overlooked yet essential factor in their operation is load stability.

Ensuring load stability during the upending process is critical not only for the protection of the material but also for maintaining workplace safety and preventing equipment damage. This article delves into why load stability matters, how it impacts various stages of coil handling, and what technical features in modern coil upenders ensure a stable and secure operation.

1. Why Load Stability Matters in Coil Handling

Load stability refers to the secure positioning and balance of the coil as it undergoes handling processes such as lifting, rotating, or moving. In coil upenders, improper load stability can lead to disastrous consequences, including coil deformation, accidents, or even machine failure. Maintaining stability is not just about ensuring that the coil stays in place during the upending process—it also plays a role in long-term efficiency and minimizing operational risks.

A slight shift in the coil's balance can result in uneven force distribution, which over time can cause damage to both the material and the machinery. Given the weight and size of the coils typically handled, ensuring proper load stability is not just a best practice—it’s a necessity for protecting assets and maintaining a safe work environment.

2. Technical Challenges of Maintaining Load Stability

Achieving load stability in coil upenders involves addressing several technical challenges. First and foremost, the sheer weight of coils presents difficulties, as even slight variations in the coil's position or shape can lead to imbalance. Additionally, coils may have different diameters, widths, and weights, which means that an upender must be adaptable to various load types.

Other technical challenges include:

-

Dynamic forces during rotation: When a coil is rotated from horizontal to vertical, forces are exerted on different points of the material. Uneven weight distribution can lead to shifts during the movement.

-

Slippage risk: The coil might slip or shift if it is not adequately secured during the upending process, causing potential damage or hazards.

-

Machine wear and tear: Over time, improper load stability can increase stress on the upender’s mechanical components, reducing its lifespan.

3. Design Features in Coil Upenders for Load Stability

Modern coil upenders come equipped with advanced design features to mitigate the risks associated with load instability. These features are aimed at securing the coil during the entire upending process, ensuring smooth, safe, and efficient operations.

Some of the most important technical innovations include:

-

Clamp mechanisms: Adjustable clamps hold the coil tightly in place during the rotation process, preventing slippage or shifting. These clamps are often customizable to fit coils of different sizes and weights.

-

Balancing sensors: Many upenders come with sensors that monitor the balance of the load in real time, automatically adjusting to ensure even weight distribution.

-

Hydraulic or mechanical locking systems: To further secure the coil, locking systems can be used to fix the coil's position before the upending motion starts, thus avoiding any sudden movements.

-

Vibration dampers: To reduce the impact of dynamic forces during the upending process, dampers absorb the shocks, protecting both the coil and the upender.

4. The Role of Automation in Enhancing Load Stability

Automation has revolutionized coil handling, including the stabilization process in upenders. Automated coil upenders use sensors, control systems, and software to precisely monitor and adjust the position of the coil throughout the upending process. With automation, the risk of human error is significantly reduced, and the machine can ensure optimal load stability for every cycle.

These systems can detect slight changes in the coil's positioning and adjust the upender’s speed, pressure, or grip to maintain stability. Automated systems also provide consistent performance, ensuring that even with different operators, the machine functions at the same high level of precision.

5. Impact of Load Stability on Safety

In industries where heavy materials like steel coils are handled daily, safety is paramount. Load stability is a critical safety factor in coil handling processes. When a coil shifts unexpectedly, the result can be catastrophic. Workers may be injured, equipment may be damaged, and operations may face costly delays.

Stabilizing the load prevents these dangerous shifts, reducing the chance of accidents. Moreover, secure handling minimizes the risk of product damage, which can result in significant financial losses, particularly when dealing with high-value materials like stainless steel or specialized alloys.

6. Economic Benefits of Maintaining Load Stability

While ensuring load stability may seem like an additional operational step, it actually brings about significant economic benefits. When coils are handled securely and efficiently, less time is spent on adjustments, repositioning, or handling errors. This leads to faster operation cycles, which directly improves throughput and productivity.

Additionally, preventing accidents, equipment damage, and coil deformation reduces repair costs, downtime, and material waste. Over time, the initial investment in an upender with advanced load stability features pays off through improved operational efficiency and reduced maintenance costs.

7. Choosing the Right Coil Upender for Optimal Load Stability

Not all coil upenders offer the same level of stability. When selecting a coil upender, it is essential to consider the following factors:

-

Capacity and size compatibility: Ensure that the upender can handle the weight and dimensions of the coils your facility processes regularly.

-

Clamping and securing mechanisms: Look for upenders with robust and customizable clamps to fit different coil sizes securely.

-

Automation capabilities: Automated systems can greatly enhance load stability, especially when dealing with heavy or irregularly shaped coils.

-

Durability and material quality: The construction quality of the upender directly impacts its ability to maintain load stability over time, especially under heavy use.

8. How to Maintain Load Stability Over Time

Once the right coil upender is in place, maintaining load stability requires ongoing attention. Regular maintenance checks should be conducted to ensure that the clamps, sensors, and hydraulic systems are functioning properly. Additionally, periodic calibration of sensors and automated systems is essential for keeping the machine operating at peak performance.

Training operators to understand the importance of load stability and the correct way to use the upender will also help prevent issues. Continuous operator training ensures that even small operational mistakes, which could lead to instability, are avoided.

Conclusion

Load stability is a critical factor in the safe and efficient operation of coil upenders. By investing in upenders equipped with advanced stability features such as automated sensors, robust clamps, and vibration dampers, companies can significantly reduce operational risks, enhance safety, and improve productivity. Ensuring that coils remain secure during handling processes not only protects the material but also safeguards workers and extends the lifespan of the machinery. In today's fast-paced industrial environments, prioritizing load stability isn't just a technical requirement—it’s a key to maintaining competitive advantage.