90-Degree Flipping Machine: Essential Equipment for Heavy-Duty Material Handling

The 90-degree flipping machine is a vital tool in various heavy industries, such as metallurgy, steel coil handling, wire reels, stamping, sheet metal processing, mold handling, paper manufacturing, refrigeration, barrel handling, and coil materials processing. It allows for safe and efficient flipping of heavy goods from vertical to horizontal positions and vice versa. Due to the significant weight of these materials, manual flipping is often impractical and risky.

When performed manually, flipping heavy materials poses several challenges. First, the inertia of these heavy objects during flipping makes it difficult to control their movement, which can lead to unexpected tipping or loss of control, potentially damaging the goods. Second, the weight and unpredictable motion of these materials pose serious safety risks to operators, increasing the likelihood of accidents and injuries. Third, the stress of flipping heavy items can damage lifting equipment such as cranes or forklifts. By using an industrial-grade 90-degree flipping machine, companies can mitigate these risks, ensuring that materials are flipped smoothly and safely.

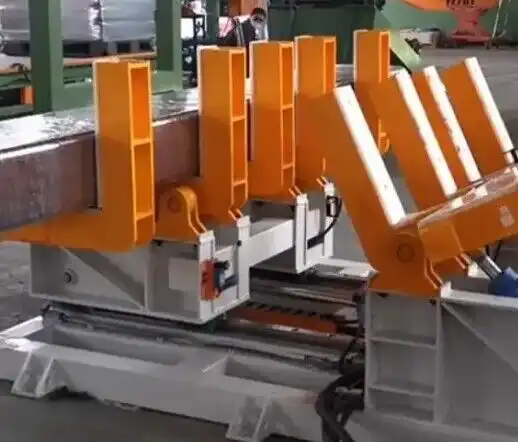

Structure and Operation of the 90-Degree Flipping Machine

The flipping machine consists of two primary parts: a base and a flipping body. To use it, the base is securely fixed to a level floor, providing stability. Operators place the material onto the flipping body, typically using a crane or forklift to handle the weight. Once loaded, a simple switch activation sets the flipping body in motion. Driven by a powerful electric motor, the flipping body performs a controlled 90-degree turn, guided by a speed reducer to maintain a stable and gradual pace. This careful control prevents sudden movements, ensuring that the load remains stable during the flip.

Once the flip is complete, the load can be easily removed using forklifts or other handling tools. The machine’s design allows it to be seamlessly integrated into an automated production line, where it can connect with other equipment like wrapping machines, cutting machines, or conveyor belts. This streamlined integration eliminates the need for separate loading and unloading steps, reducing manual labor and saving valuable time.

Advantages of the 90-Degree Flipping Machine

The 90-degree flipping machine offers numerous advantages, especially in high-volume industrial settings:

-

Enhanced Safety: By automating the flipping process, the machine reduces human interaction with heavy objects, minimizing the risk of operator injury. Its stable base and controlled motion ensure a smooth flipping process without sudden jerks or shifts that could endanger operators or damage materials.

-

High Efficiency: The machine’s automated and straightforward operation speeds up material handling, improving productivity by reducing the time and effort required for flipping tasks. This efficiency is particularly valuable in industries where time and labor costs are critical.

-

Reliable and Easy to Use: With a user-friendly control system, the flipping machine is simple to operate, requiring minimal training for operators. Its robust structure and reliable motor allow it to handle large volumes and heavy loads consistently, making it a valuable addition to any industrial workflow.

-

Flexible Integration: The flipping machine can be connected to a range of other industrial equipment, forming part of a larger, fully automated production line. This integration reduces the need for separate handling steps and enhances overall workflow efficiency.

Conclusion

The 90-degree flipping machine is an essential piece of equipment for industries that handle heavy or bulky materials. Its ability to safely and efficiently flip heavy goods from one orientation to another minimizes risks, reduces manual labor, and ensures a smooth workflow. By investing in a 90-degree flipping machine, companies can enhance workplace safety, boost operational efficiency, and provide a reliable solution for handling large and weighty materials.