How Mobile Pallet Turners Improve Safety and Efficiency in Pallet Exchanging

Pallet exchanging is a crucial aspect of logistics, warehousing, and material handling industries. It ensures that products can be efficiently transferred between storage systems, transportation vehicles, and production lines. However, the traditional method of manually exchanging pallets comes with significant risks, including worker injury, product damage, and time inefficiencies. Mobile pallet turners are rapidly emerging as a solution to these challenges, providing a safer and more efficient way to handle pallet exchanging tasks.

In this article, we will explore how mobile pallet turners enhance safety and operational efficiency, providing businesses with a more reliable, streamlined process. We will also delve into the benefits and key features of mobile pallet turners, helping you understand why they are essential in modern logistics and warehousing.

1. The Role of Mobile Pallet Turners in Modern Warehousing

In a busy warehouse environment, pallet exchanging is a common task that can significantly impact the flow of operations. The manual handling of pallets not only slows down processes but also exposes workers to potential hazards. Mobile pallet turners offer a mechanized solution to these challenges, eliminating the need for physical labor and reducing the risk of injury.

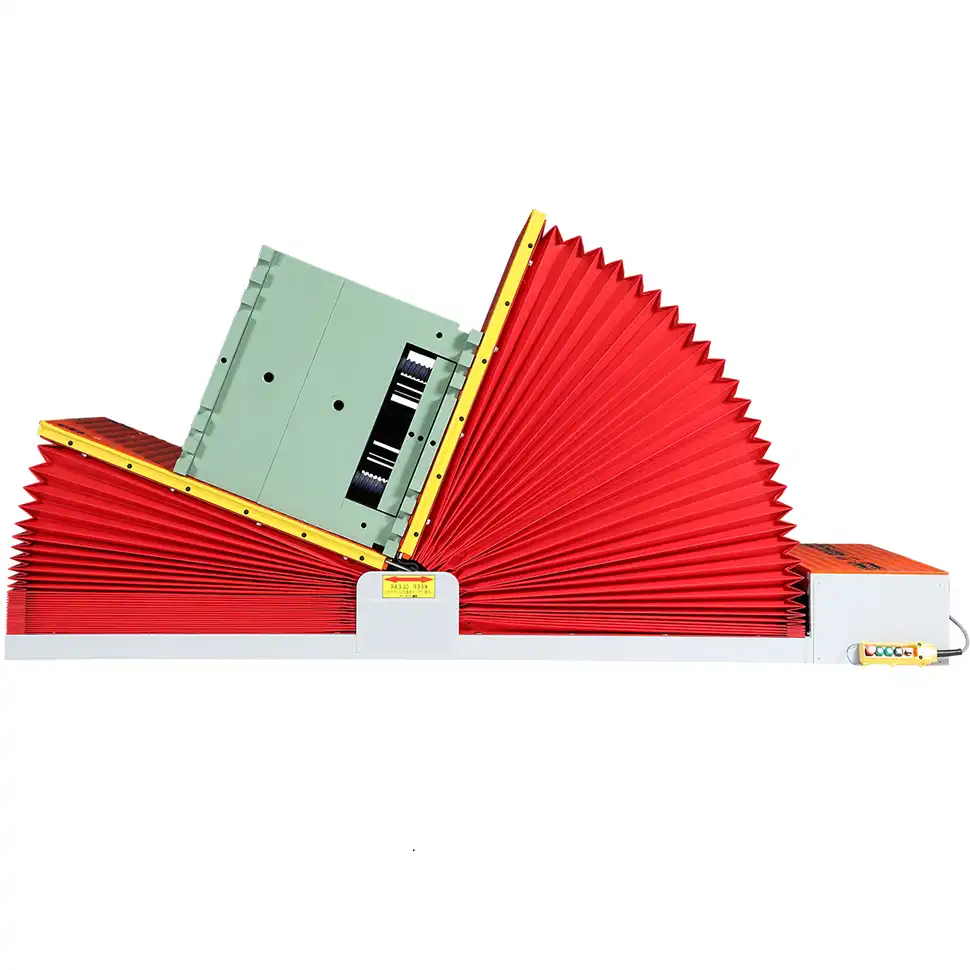

By automating the pallet exchange process, mobile pallet turners enable workers to move loads faster and more efficiently. This equipment is designed to rotate, tilt, or flip pallets, allowing easy access to products stored on them. Whether it's for stacking, unstacking, or repositioning goods**, mobile pallet turners help minimize disruptions in the supply chain, contributing to better productivity.

2. How Mobile Pallet Turners Improve Safety

Safety is a top concern in any warehouse or industrial setting, where heavy lifting and repetitive tasks often lead to accidents. The traditional method of manually exchanging pallets requires workers to bend, lift, and twist, putting them at risk of strain, fatigue, and injury. Mobile pallet turners address these concerns by automating the movement and flipping of pallets, allowing workers to complete their tasks without exerting physical effort.

Key safety benefits include:

-

Reduced manual handling: Workers no longer need to physically lift or rotate pallets, reducing the risk of injuries such as back strains and muscle pulls.

-

Improved ergonomics: Mobile pallet turners are designed to be ergonomically efficient, minimizing awkward body positions that can cause long-term injuries.

-

Enhanced load stability: These machines provide stable and secure handling of heavy loads, preventing pallets from tipping over or shifting unexpectedly.

The integration of mobile pallet turners into daily operations helps create a safer working environment, where the risk of injuries is significantly reduced, and employee well-being is prioritized.

3. Efficiency Gains Through Mobile Pallet Turners

Apart from safety, mobile pallet turners greatly enhance the efficiency of pallet exchanging. Traditional methods of pallet exchanging are time-consuming, often requiring multiple workers to perform the task manually. With a mobile pallet turner, a single operator can handle pallet exchanges quickly and with precision.

Efficiency improvements include:

-

Faster pallet rotation: Mobile pallet turners can flip and rotate pallets in seconds, reducing the time spent on manual repositioning.

-

Labor cost reduction: By minimizing the number of workers needed for pallet handling, businesses can cut down on labor costs and redeploy staff to other critical tasks.

-

Increased throughput: As mobile pallet turners streamline the exchange process, the overall productivity of the warehouse increases. This allows companies to meet customer demands faster and more efficiently.

The automation provided by mobile pallet turners ensures that pallet exchanging is no longer a bottleneck in operations, enabling companies to achieve higher throughput and improve workflow consistency.

4. Key Features of Mobile Pallet Turners

Understanding the key features of mobile pallet turners is essential to fully grasp their value in the workplace. These features ensure that pallet turners are not only efficient but also versatile enough to handle different types of pallets and load conditions.

A. High Load Capacity

Mobile pallet turners are designed to handle heavy loads, often with capacities ranging from 1,000 kg to over 2,500 kg. This makes them ideal for industries that deal with heavy or bulky items, such as food and beverage, pharmaceuticals, and manufacturing.

B. Adjustable Clamping Pressure

For delicate or fragile products, the clamping pressure can be adjusted to ensure that the load is handled gently without causing damage. This feature is particularly beneficial for industries that require careful handling of products during pallet exchanges.

C. Compact and Mobile Design

Unlike stationary pallet turners, mobile pallet turners are equipped with wheels or casters, allowing them to be easily moved around the warehouse. Their compact design ensures that they can navigate tight spaces and reach various workstations without disrupting other activities.

D. 180-Degree Rotation

The 180-degree rotation feature allows the pallet to be fully flipped, making it easier to access goods that are stored on the pallet’s underside or when switching between pallets of different materials.

These features combine to make mobile pallet turners an indispensable tool in warehouses and logistics centers, offering the versatility and functionality needed to handle a wide range of pallet types and operational requirements.

5. The Importance of Load Stability in Mobile Pallet Turners

When handling large or bulky loads, load stability is critical for ensuring safety and preventing product damage. Mobile pallet turners are designed to securely hold and rotate loads with precision, preventing them from slipping or falling during the exchange process.

The adjustable clamping pressure feature ensures that the machine can accommodate different types of loads, whether they are rigid, soft, or irregularly shaped. By maintaining consistent load stability, mobile pallet turners help businesses avoid accidents, product damage, and costly delays in the supply chain.

The combination of secure handling and precision rotation makes mobile pallet turners the ideal solution for improving safety and efficiency in pallet exchanges, especially when dealing with high-value or fragile goods.

6. Applications of Mobile Pallet Turners in Different Industries

Mobile pallet turners are versatile machines that serve a wide range of industries, from food and beverage to pharmaceuticals and heavy manufacturing. Each industry requires efficient and safe pallet handling, making pallet turners a critical asset in improving operations. Let's take a closer look at how different industries benefit from this technology.

A. Food and Beverage Industry

In the food and beverage industry, hygiene and safety are top priorities. Mobile pallet turners help streamline processes such as pallet exchanges in cleanrooms or cold storage facilities, ensuring that food products are handled with minimal contamination risk. The ability to securely clamp and rotate pallets with delicate items, such as bottled drinks or packaged foods, reduces the chance of breakage or product loss.

B. Pharmaceutical Industry

In the pharmaceutical sector, precise handling of products is critical due to the strict regulations governing the industry. Mobile pallet turners enhance safety by providing a stable and controlled method for pallet exchanges, ensuring that fragile items, such as medical devices or pharmaceutical ingredients, are not compromised during transport or storage.

C. Heavy Manufacturing

For industries that handle heavy materials like steel coils, automotive parts, or construction materials, mobile pallet turners are essential. Their high load capacity and ability to manage large or awkwardly shaped items make them invaluable for streamlining pallet exchanging tasks and ensuring that workers are not exposed to unnecessary risks when handling heavy loads.

7. How Mobile Pallet Turners Reduce Product Damage

One of the primary benefits of using mobile pallet turners is their ability to significantly reduce product damage during pallet exchanges. Manually flipping or exchanging pallets can result in dropped items, product misalignment, or damage due to uneven pressure during handling.

Mobile pallet turners provide even distribution of clamping pressure and a controlled flipping mechanism, which protects delicate items such as glassware, electronics, or pharmaceuticals from getting damaged. Additionally, the precision with which pallet turners handle the products ensures that they maintain their quality throughout the process, reducing costly product losses for businesses.

This feature is especially beneficial for industries that handle fragile or high-value goods, where any damage to products can lead to significant financial loss.

8. Labor Cost Savings with Mobile Pallet Turners

Integrating mobile pallet turners into your operations not only enhances efficiency but also leads to substantial labor cost savings. Traditional pallet exchanging methods often require multiple workers to manually lift, rotate, and reposition pallets. This manual labor is not only time-consuming but also increases the risk of injury, which can further increase labor costs due to potential downtime or worker compensation claims.

With a mobile pallet turner, a single operator can perform pallet exchanges in a fraction of the time it takes a team of workers to do it manually. This reduction in manpower requirements frees up employees to focus on other critical tasks, optimizing workforce utilization and ultimately saving on labor costs.

By automating the pallet exchange process, businesses can minimize human intervention while maintaining a steady flow of operations, leading to long-term cost savings.

9. Choosing the Right Mobile Pallet Turner for Your Business

When selecting a mobile pallet turner for your operations, there are several factors to consider to ensure that the machine fits your specific needs. The first consideration is the load capacity—make sure that the turner can handle the weight of your pallets, whether they’re loaded with heavy materials or fragile goods.

Next, evaluate the adjustability of the machine. Different products may require varying levels of clamping pressure to avoid damage during pallet exchanges. A turner with customizable clamping pressure will provide the flexibility to handle a variety of products.

Mobility is another important factor. A compact design that can easily navigate through tight warehouse spaces ensures that the turner can be moved to different workstations without disrupting the flow of other operations.

Finally, prioritize safety features such as emergency stop buttons, load sensors, and anti-slip platforms to protect both your employees and your products.

10. Conclusion: The Future of Safe and Efficient Pallet Handling

As industries continue to seek ways to improve safety and efficiency, mobile pallet turners have proven to be an indispensable tool in pallet exchanging processes. By automating the exchange of pallets, these machines significantly reduce the risk of worker injury, increase throughput, and minimize product damage. The combination of speed, precision, and load stability offered by mobile pallet turners makes them a must-have in industries where pallet handling is frequent and critical to operations.

From food and beverage to heavy manufacturing, mobile pallet turners provide a versatile solution for improving the efficiency of material handling tasks. Businesses that invest in this technology will not only benefit from safer working conditions but also enjoy cost savings, improved productivity, and a streamlined workflow.

Investing in a high-quality mobile pallet turner is a step toward optimizing your operations, ensuring smoother pallet exchanges, and setting your business up for long-term success in an increasingly competitive market.