WHAT IS THE MOLD FLIPPER

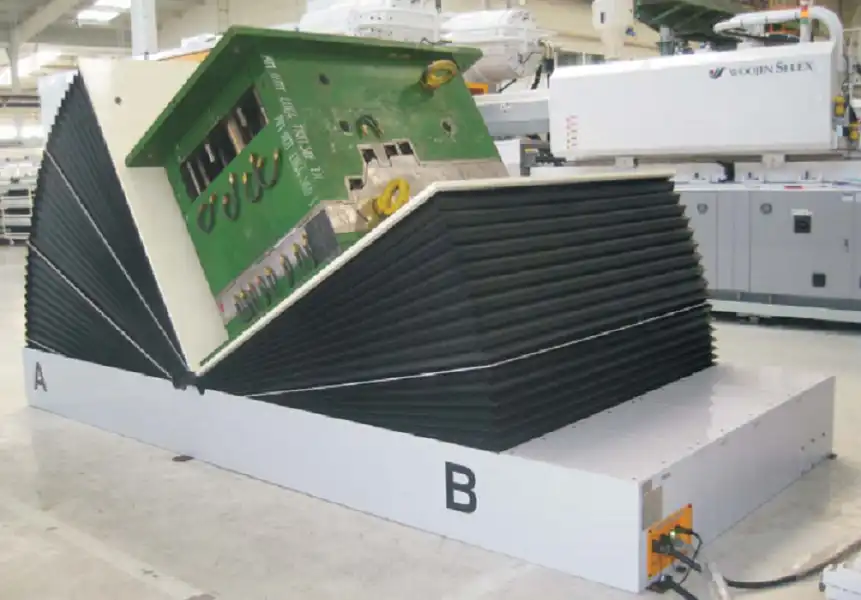

A mold flipper is a specialized piece of equipment used in manufacturing facilities to safely invert and reposition heavy molds, die, coil. These devices allow workers to efficiently access all sides of a mold for cleaning, maintenance, and repair. Mold flippers are designed with a working table and flipping driving system that is hydraulic or mechanical flipping mechanism. It is to securely grip and rotating the mold, dies with different angle and dirction.

Own Designing Team

We create custom working table poer dies & mold specific.

Self-Manufacturing

Our factory producting with quality control at every step.

After-Sales Support

Providing on-site after service and solution response in 24 hours.

Mold Flipper

-

Mold Flipper for 2TThe Mold Flipper Machine for 2T is vital for handling and flipping medium to large molds. Best used with vertical die spotting presses, it boosts mold maintenance and repair, making it key for mold management....

-

Mold Flipper for 5TEnhance workshop efficiency with our 5T Mold Flipper Table, designed for safe, precise handling of heavy molds and dies. FHOPE is top manufacurer privide the new and second hand mold flipper...

-

Mold Flipper for 10TDie Flipper | mold flipping table for 10T Mold Flippers, designed to specific mold specifications, efficiently and safely turn molds for maintenance. These flippers accommodate a wide range of weights, supporting mold capacities from 2 to 10 metric tons, ensuring versatile and reliable performance for diverse industrial needs. Te...

-

Mold Flipper for 20TThe Mold Flipper for 20T is an essential tool in the injection molding industry, designed to handle heavy loads up to 20 tons. This robust equipment enhances operational efficiency by allowing quick, safe flipping and precise positioning of large molds, significantly reducing downtime and improving production flow in manufacturin...

-

Mold Flipper for 30TThe Mold Flipper for 30T is designed to handle and accurately position large molds up to 30 tons. This powerful device streamlines manufacturing processes by rapidly flipping molds, reducing downtime, and improving safety in high-volume production settings. Essential for enhancing operational efficiency in heavy-duty environments...

-

Mold Flipper for 40TThe Mold Flipper for 40T is engineered to handle extremely heavy molds, with a capacity to manage up to 40 tons. This robust machinery ensures rapid and safe mold flipping, significantly enhancing productivity and reducing downtime in large-scale industrial environments. A key asset for optimizing manufacturing efficiency....

-

90 Degree Mold Flipper for 10TThe 90 Degree Mold Flipper for 10T is an efficient industrial tool designed specifically for molds weighing up to 10 tons. It enables precise 90-degree flipping, featuring a robust construction and easy operation. This machine significantly enhances productivity and safety in heavy-duty manufacturing environments....

-

90 Degree Mold Flipper for 30T90 Degree Mold Flipper for 30T is an innovative tool designed to enhance efficiency in mold handling. Its 90-degree rotation feature allows for easy access and positioning of molds, reducing manual strain. Ideal for industrial applications, this flipper improves workflow and safety, making it an essential addition to any producti...

Parameters:

| Item | FPMF-02 | FPMF-05 | FPMF-10 | FPMF-20 | FPMF-30 | FPMF-40 |

|

Power Supply (V/Hz) |

Per requirement |

|||||

|

Power (Kw) |

4.5 | 5.5 | 8.5 | 10.5 | 12.5 | 16.5 |

|

Max. Loading (T) |

2 | 5 | 10 | 20 | 30 | 40 |

|

Table size (mm) |

Per Load size | |||||

|

Speed (sec) |

20-30 | 20-30 | 20-30 | 20-30 | 20-35 | 20-35 |

|

Machine Weight (T) |

2.0 | 2.5 | 3.0 | 3.5 | 4.0 | 5.0 |

|

Machine size (mm) |

Desinged Per Load size | |||||

| Warrantee | 2 years | |||||

Note: Working table size can be customized per diferernt mold specification.

WHY CHOOSE FHOPE FOR MOLD HANDLING

- Safety: FHOPE machines prioritize user safety with built-in CE protective features..

- Uptime: Our industrial solutions adapt to any load and speed, ensuring continuous, jam-free operation..

- Eay to us: user-friendly, requiring minimal training and maintenance, and consistently delivers quality and efficiency.

- Performance: leads the industry with 15+ years of innovative, updateing technology, consistently delivers safe-to-ship loads..

- 24/7 support:unparalleled 24/7 support and service for all its machines, backed by a best-in-class warranty.

HOW TO MAKE A MOLD FLIPPER

- Design and Engineering: Initiates with 3D simulation to define load capacity and rotation mechanics, utilizing CAD and FEA for robust, functional designs.

- Material Selection: High-grade steel is chosen for the structure for durability; durable gear, beraing, hydraulic systme are based on operational requirements.

- Component Fabrication: Precision CNC machines craft each component, ensuring perfect fit and functionality.

- Assembly: Components are assembled meticulously, integrating necessary hydraulic or electrical systems, with a thorough check of all connections.

- Testing: Comprehensive load testing confirms the machine's capacity to handle specified weights safely.

- Finishing: A protective coating is applied to resist rust and wear, with customization of control panels and interfaces per customer specifications.

- Quality Control & Delivery: Continuous quality assessments during production, with a final inspection pre-delivery. Machines are shipped partially disassembled for ease of transport and installation.

Frequently Asked Questions

We've compiled key FAQs about mold flippers for your convenience. If you don't find your question, call us at +8613951501635 or email info@fhopepack.com.

> What's The Warranty Period?

> Do You Have Local Installation?

> What are the Payment Options?

> Is International Shipping Available?

> What About The After Service?

> How to Guarantee The Quality?

> Can Products be Customized?

> What is the Return Policy?

SHOWCASE & NEWS

Product Inquiry

Our team will reply in 24 hours

![]() Email: info@fhopepack.com

Email: info@fhopepack.com

![]() Whatsapp: 0086-13951501635

Whatsapp: 0086-13951501635