In the multifaceted realm of logistics and warehousing, the way materials are handled plays a pivotal role in determining overall productivity and safety. One essential piece of equipment that significantly enhances this efficiency is the pallet tipper, particularly the 95-degree pallet tipper. This innovative machinery is engineered to securely tip, rotate, and exchange pallets loaded with goods, which greatly reduces the reliance on manual labor. By automating these processes, businesses can achieve faster operational speeds and reduce the risk of workplace injuries, creating a more efficient and safer work environment.

In this article, we will explore the various functionalities and benefits of

95-degree pallet tippers, as well as their applications across different industries. We will also compare several models currently available on the market to help identify the best options for various business needs. Whether you’re managing a large-scale warehouse or a smaller logistics operation, understanding the capabilities and advantages of these machines can lead to improved material handling processes, increased throughput, and a better return on investment.

Parameters:

Model

|

FPFZ-01L

|

Length:

|

1000-1200mm

|

Width:

|

1000-1200mm

|

Height:

|

1000-2000mm

|

Max.Loading

|

1000 | 2000Kg

|

Changing speed

|

20-35sec

|

Turning degree

|

90-95°

|

Driving

|

Hydraulic system

|

Control

|

Panel/ remote

|

Power

|

4.5KW

|

Safety

|

Fence | light beam

|

The Best 95-Degree Pallet Tipper for Different Industry Applications: A Detailed Comparison in Pallet Exchanging Equipment

Introduction

In the diverse world of logistics and warehousing, the efficiency of how materials are handled can significantly influence the overall productivity and safety in the workplace. One of the critical machines that help achieve this efficiency is the pallet tipper, specifically the 95-degree pallet tipper. This equipment is designed to securely tip, rotate, or exchange pallets containing goods, thereby minimizing the manual labor required and enhancing the speed of operations. In this article, we will dive deep into the functionalities, advantages, and industry applications of 95-degree pallet tippers, comparing various models to determine the best options available in the market today.

Understanding Pallet Tippers

Pallet tippers are mechanical devices used to lift and tilt pallets to transfer goods from one type of pallet to another or to reorient the load for various purposes. The 95-degree tilt functionality is particularly useful as it allows almost complete inversion, making it easier for operations involving liquid products or where precise handling is necessary.

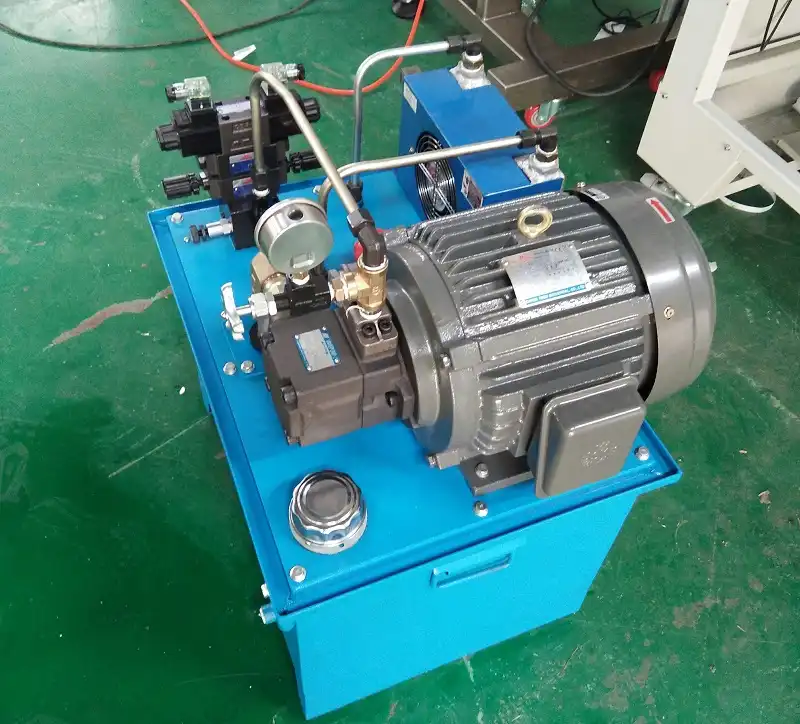

Key Components of a Pallet Tipper

-

Frame: Robust construction that supports the entire mechanism.

-

Tilting Mechanism: Hydraulic or pneumatic systems that provide the energy required for tilting.

-

Platform: Where the pallet is placed and secured during the tipping process.

-

Control System: Either manual or automated controls that dictate the operations of the tipper.

Benefits of Using a 95-Degree Pallet Tipper

-

Improved Safety: Reduces the risk of workplace injuries associated with manual handling of heavy loads.

-

Increased Efficiency: Speeds up the process of pallet exchange and goods handling.

-

Versatility: Can handle different types of materials, including boxes, bags, drums, and more.

-

Reduced Labor Costs: Decreases the need for physical labor, thereby reducing labor costs.

Industries That Benefit From Pallet Tippers

Manufacturing

In manufacturing, speed and precision are paramount. Pallet tippers expedite the process of moving raw materials or finished goods, thereby enhancing throughput.

Food and Beverage

Hygiene and handling are crucial in the food sector. Pallet tippers ensure that products are handled minimally and within sanitary standards, especially important for products like bottled beverages.

Pharmaceuticals

Given the strict regulations in the pharmaceutical industry, pallet tippers help in maintaining compliance with safety standards, particularly in handling sensitive materials safely.

Logistics and Warehousing

Efficiency in storage and transportation of goods can be significantly boosted by using pallet tippers, particularly in warehouses that handle a high volume of palletized goods.

Comparative Analysis of Top 95-Degree Pallet Tippers

Model A

Features:

-

High-load capacity

-

Advanced safety features

-

Energy-efficient hydraulic system

Pros:

-

Suitable for heavy industrial applications

-

Low maintenance cost

Cons:

-

Higher initial investment

Model B

Features:

-

Compact design

-

Environmentally friendly electric model

Pros:

-

Ideal for smaller spaces

-

Reduced carbon footprint

Cons:

Model C

Features:

-

Versatile handling features

-

Easy integration with existing conveyor systems

Pros:

-

High adaptability

-

Moderate price point

Cons:

-

Requires additional setup

Technological Innovations in Pallet Tippers

Advanced features such as automated control systems, integrated weighing scales, and IoT connectivity are now being incorporated into pallet tippers to enhance functionality and interconnectivity with other warehouse management systems.

Safety and Maintenance Considerations

Safety Features

-

Emergency stop buttons

-

Automatic load detection

-

Stability controls

Maintenance Tips

-

Regular hydraulic system checks

-

Scheduled professional inspections

-

Immediate repair of any wear and tear

Choosing the Right Pallet Tipper for Your Needs

When selecting a pallet tipper, consider factors like maximum load capacity, compatibility with existing systems, space availability, and specific industry requirements. It is also vital to choose a supplier with reliable customer support and service offerings.

Case Studies: Successful Implementations

Several leading companies have successfully integrated 95-degree pallet tippers into their operations, showing notable improvements in efficiency, safety, and cost management.

Conclusion

The 95-degree pallet tipper is a pivotal piece of equipment across various industries, significantly contributing to operational efficiency and safety. When choosing the best pallet tipper, it is crucial to consider specific operational needs, space constraints, and budget. With the right selection, businesses can achieve faster operational times, improved safety, and reduced costs, leading to enhanced overall productivity and profitability. By understanding the detailed comparisons and current technological advancements provided in this article, companies are well-equipped to make informed decisions about integrating these powerful tools into their workflows.