Weight Capacity and Speed: Understanding Coil Upender Performance Metrics

Coil upenders are essential equipment in industries that handle heavy coils, such as steel, aluminum, and other manufacturing sectors. Choosing the right coil upender can dramatically improve efficiency and safety in handling, but understanding the key performance metrics—specifically weight capacity and speed—is crucial. These two factors directly impact how well the equipment will perform in a given environment. This article will break down the relationship between weight capacity and speed, their impact on performance, and how to evaluate these metrics to make the best choice for your operation.

1. What is a Coil Upender?

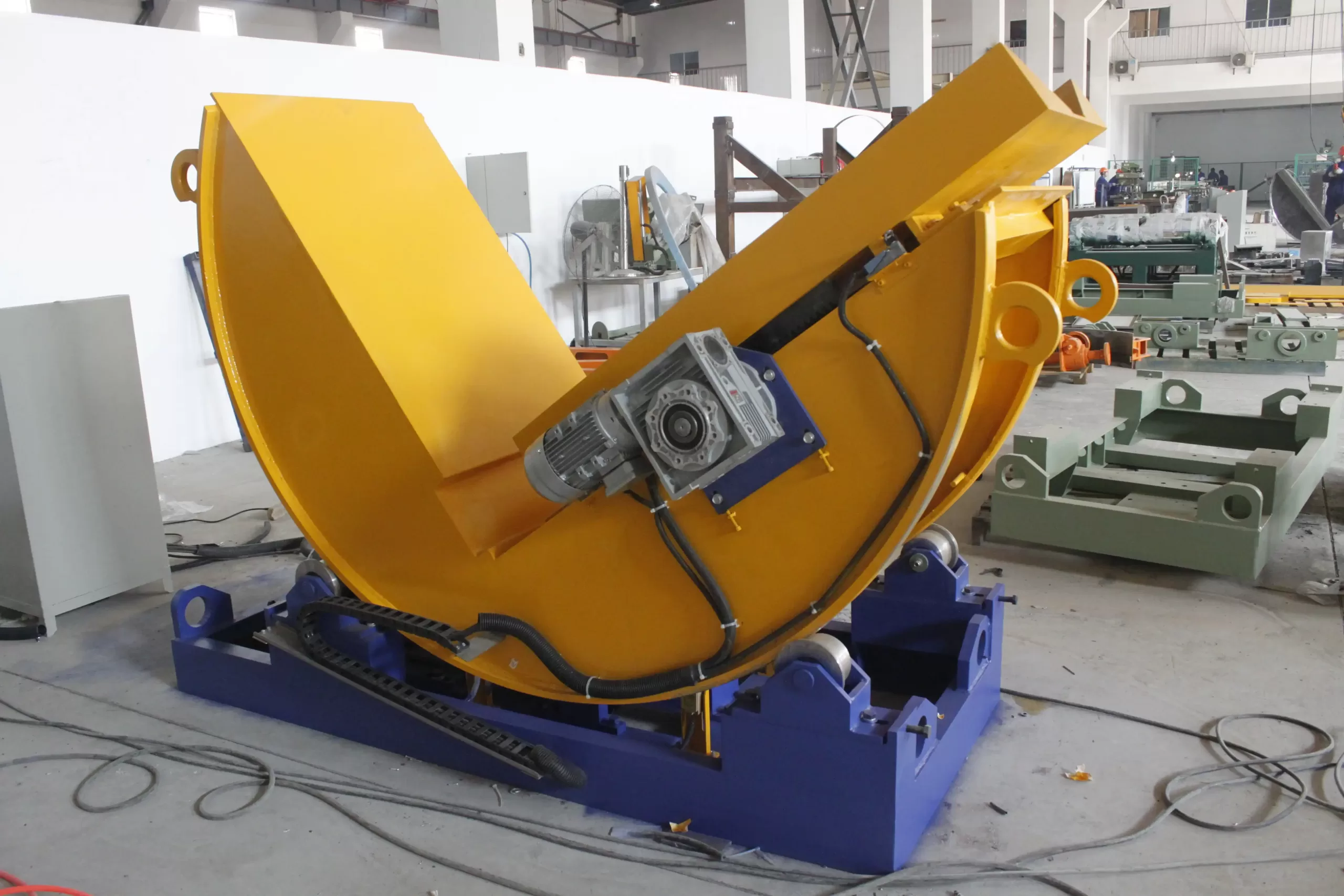

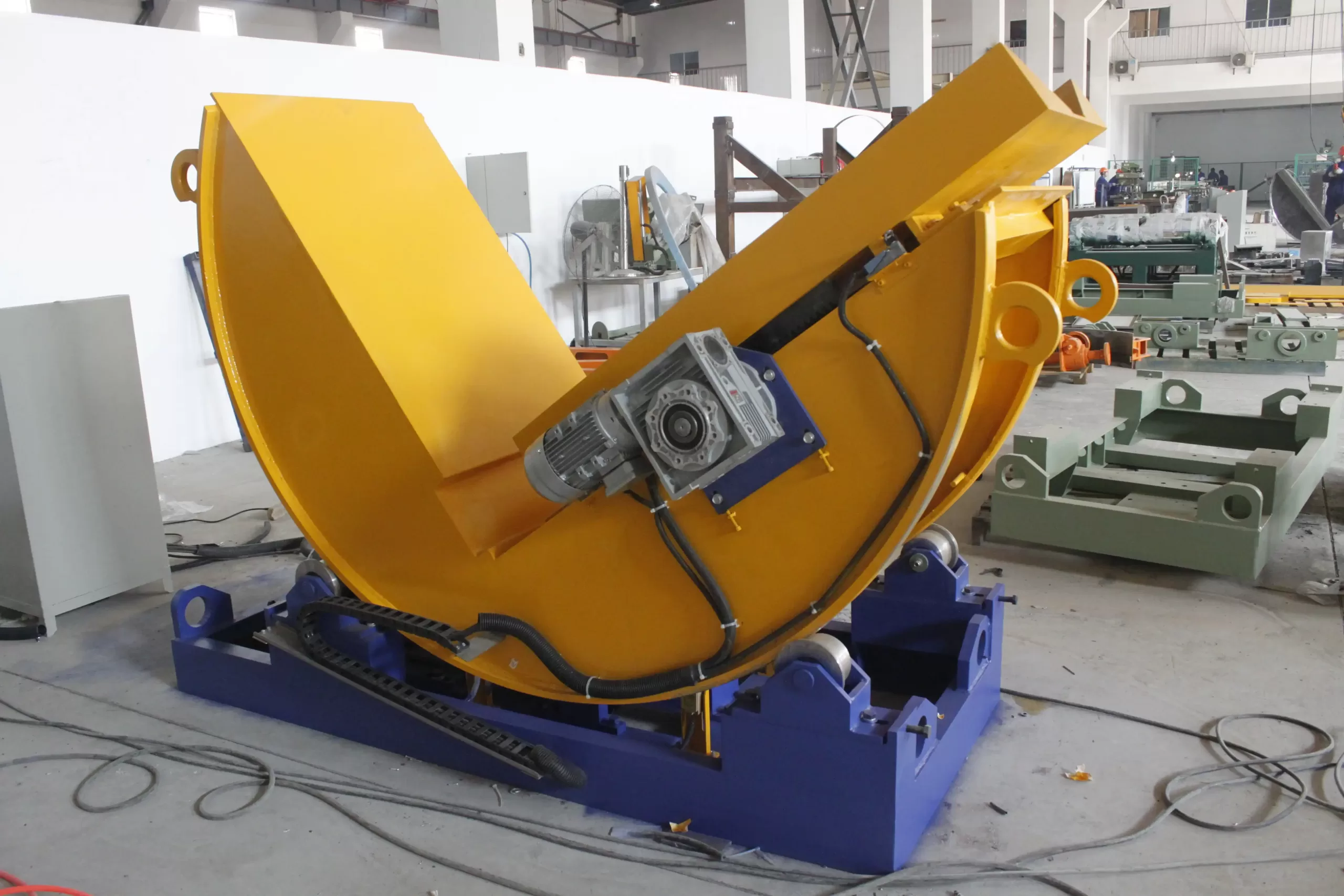

A coil upender is a machine designed to rotate or flip heavy coils from one position to another, typically from horizontal to vertical, or vice versa. This function is critical for industries where coils need to be repositioned for processing, shipping, or storage. The machine operates with a hydraulic or mechanical system, depending on the model, to handle loads ranging from a few tons to over 50 tons. Its primary benefits include improving worker safety, reducing handling time, and minimizing the risk of coil damage during movement.

2. Why Weight Capacity Matters in Coil Upenders

Weight capacity is one of the most important metrics in determining a coil upender's suitability for a specific operation. The weight of the coils can vary significantly, depending on the material and size, so choosing a machine with the appropriate capacity is critical for both safety and efficiency.

-

Safety First: Overloading a coil upender beyond its designed weight capacity can lead to catastrophic equipment failure. This poses serious risks to operators and can cause costly damage to both the machine and the coils themselves.

-

Operational Efficiency: A coil upender with insufficient weight capacity will require more frequent handling, as you may need to split larger coils into smaller batches for handling. This can significantly slow down operations and lead to inefficiencies.

When evaluating weight capacity, always consider the heaviest coils in your inventory. It’s often advisable to choose a model with a slightly higher capacity than your maximum coil weight to ensure operational flexibility.

3. Speed: A Key Factor for Productivity

Speed is another crucial performance metric that directly impacts productivity. In a high-demand environment, the faster a coil upender can flip and reposition coils, the more throughput your operation can handle. Speed is typically measured in terms of how quickly the machine can complete a full rotation or upend cycle.

-

Cycle Time: This is the total time it takes for the machine to complete one full upending action, including the loading and unloading process. Faster cycle times mean higher productivity, but it’s important to balance speed with safety.

-

Adjustable Speed Settings: Some advanced coil upenders offer adjustable speed settings, which allow operators to optimize the machine's performance based on the specific needs of each coil or job. For example, lighter coils may allow for faster operations, while heavier loads may require slower, more cautious handling.

4. The Relationship Between Weight Capacity and Speed

The relationship between weight capacity and speed is often misunderstood. A higher weight capacity does not necessarily mean a slower machine, but there is a correlation between the two. Generally, machines designed to handle extremely heavy loads may have longer cycle times because more robust mechanical systems are required to safely upend large coils. Conversely, machines with lighter weight capacities can operate at faster speeds because less force is needed to move the coil.

That said, the best machines find an optimal balance between weight capacity and speed, allowing for efficient handling of heavy coils without sacrificing safety or operational throughput. Always check the specifications for both metrics when comparing models.

5. Factors Affecting Performance Metrics

Several factors can influence both weight capacity and speed in a coil upender:

-

Hydraulic vs. Mechanical Systems: Hydraulic coil upenders generally offer higher weight capacities, as the hydraulic pressure can be fine-tuned to handle very heavy loads. Mechanical systems, while often faster, may not have the same load-bearing capabilities.

-

Motor Power: The strength and efficiency of the motor play a critical role in determining the speed of the upender. A more powerful motor can move heavier coils faster but may require more energy to operate.

-

Design and Build Quality: The structural integrity of the coil upender affects both its weight capacity and operational speed. Machines built with high-quality materials and robust engineering can often handle higher capacities without compromising on speed.

6. Optimizing for Your Specific Needs

To select the right coil upender, it’s essential to consider your specific operational needs:

-

Types of Coils: Are you handling steel, aluminum, or other materials? Each material has different weight and handling characteristics, which should guide your choice of upender.

-

Frequency of Use: How often will the machine be in operation? High-frequency use requires a machine with both a high weight capacity and faster speeds to maintain productivity.

-

Workplace Safety Standards: Ensure that the chosen machine complies with industry safety standards, particularly regarding maximum weight capacity and the machine’s braking system to prevent accidents during high-speed operation.

7. Long-Term Impact of Weight Capacity and Speed

Investing in a coil upender with the right weight capacity and speed can have a long-term impact on your operation's overall efficiency and cost-effectiveness. Machines that are under-specced may require frequent repairs, maintenance, and could even lead to costly downtime if coils are damaged due to overloading or improper handling.

In contrast, a well-matched coil upender will enhance workflow efficiency, reduce manual labor, and ensure that operations run smoothly for years to come. The initial cost of a high-quality machine may be higher, but the return on investment (ROI) is realized through increased productivity and fewer operational disruptions.

8. Future Trends in Coil Upender Technology

As industries evolve and technology advances, we are likely to see innovations that further enhance the weight capacity and speed of coil upenders. Future models may incorporate AI-driven systems that can automatically adjust speed and handling settings based on the specific coil being moved. Additionally, the integration of IoT (Internet of Things) technology could allow real-time monitoring of coil upender performance, providing insights into optimal speed and load settings for each job.

Another exciting development is the rise of customizable coil upenders that allow operators to tailor machine settings more precisely to their operational needs. This could include advanced weight-sensing technology that dynamically adjusts speed for optimal safety and efficiency.

Conclusion

When it comes to selecting a coil upender, understanding the balance between weight capacity and speed is key to making the right choice. These metrics not only impact your operation's productivity but also play a crucial role in ensuring the safety of your workers and the longevity of your equipment. By carefully considering your specific operational needs, material handling requirements, and long-term goals, you can select a coil upender that meets your performance expectations and contributes to a more efficient and safe workplace.

Whether you're handling lightweight coils or heavy-duty materials, the right combination of weight capacity and speed will ultimately dictate how well your operation performs in the long run. Choose wisely, and your coil upender can become a cornerstone of improved productivity and safety in your facility.