Support

-

Maintenance Requirements: How Different Coil Upenders CompareIn this article, we compare the maintenance needs of different coil upenders, focusing on critical aspects like wear and tear, part replacements, and servicing intervals. Understanding these differences will help companies choose a model that aligns with their maintenance capabilities, ensuring efficient and cost-effective long-t...

-

What You Can Expect from Our After-Sales Support for Steel CoIn this article, we’ll dive into the various elements of our after-sales support, outlining the specific services you can expect and the technical details that make our support offerings stand out from the competition. Our goal is to help you understand how our support services not only protect your investment but also improve ...

-

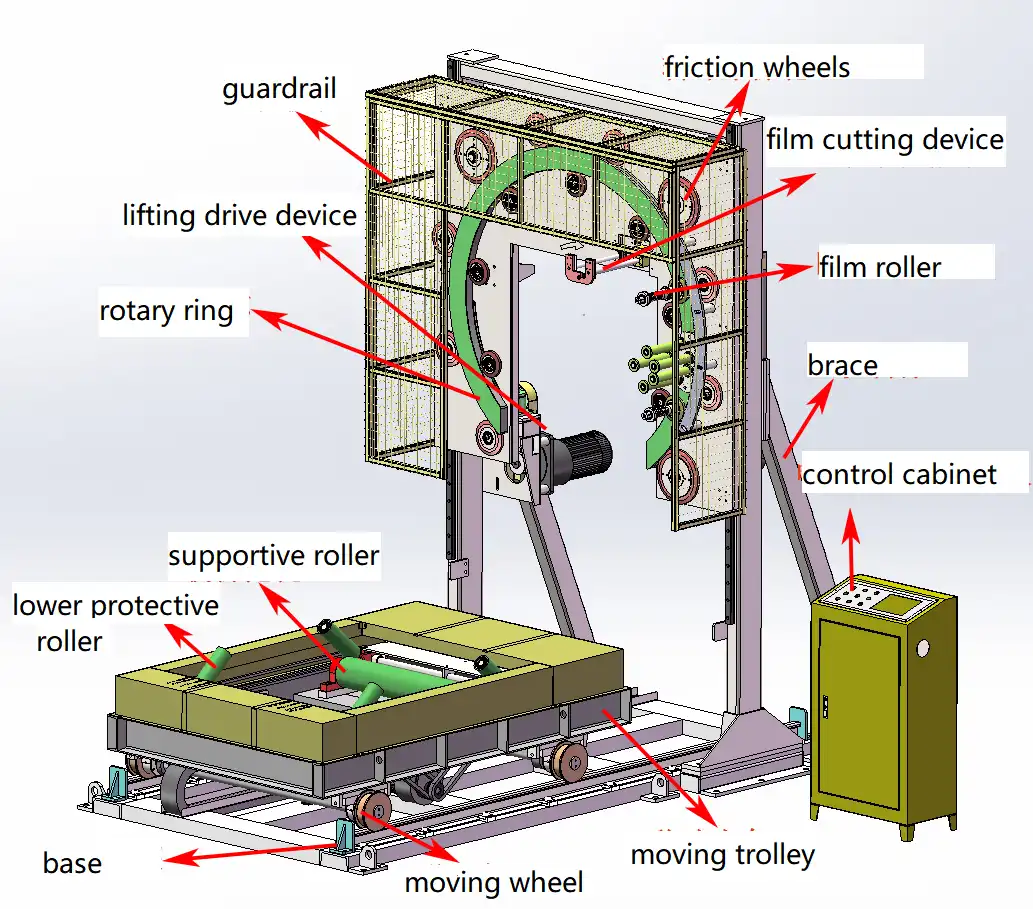

Main Components Guideline For The Hydraulic Systems Used In FMain Components Guideline For The Hydraulic Systems Used In FHOPE This document offers a detailed guide on the operation and settings for the steel wire coil wrapping machine, designed specifically for packaging ring-shaped products such as coils of copper, steel, and aluminum, as well as hoses and wires. It highlights the machin...

-

How to Use and Maintain the Storage Battery for Mobile PalletThe battery serves as a vital component of the mobile pallet inverter, fueling its functions and boosting its efficiency. Proper maintenance is crucial for optimizing the battery's longevity and performance. We suggest that customers invest in a spare battery to guarantee uninterrupted operation. Below, you'll find essential reco...

-

The guideline of the coil wrapping machine operation & settinThe guideline of the coil wrapping machine operation setting This document provides a guide on operating and setting the steel wire coil wrapping machine, detailing its application across various ring-shaped products and emphasizing automated control features for efficient packaging. Overview and Application Fields The steel wire...

-

The steps of the Coil Packing Line ProductionThe Coil Packing Line Production Process is designed to efficiently prepare and secure coils of various metals for shipping and storage. It encompasses steps such as thorough cleaning, application of rust preventatives, and wrapping with durable materials to protect against environmental factors. Automation plays a crucial role i...

-

Framework for Packing Machine Original DesignTo create an original design for a packing machine in an industrial setting, a structured approach is essential to ensure functionality, safety, and manufacture ability. Below is a comprehensive framework that outlines the design process and standards for industrial equipment, specifically a packing machine. Framework for Packing...

-

Tips for Installing and Maintaining a horizontal WrapperTips for Installing and Maintaining a horizontal Wrapper A horizontal wrapper machine can significantly improving the long shape products packging. By machine wrapping, it enhances productivity, reduces film costs, and minimizes product damage. Most importantly, it reduces the physical strain associated with manual wrapping. Howe...

-

What Is The LOTO Safety System For The Packing MachineWhat is the LOTO safety system for the packing machine Lockout-tagout (LOTO) is a safety procedure that is used in industry and research settings to ensure that machines are properly shut off and not started up again prior to the completion of maintenance or repair work. It requires that hazardous energy sources be "isolated and ...

-

Things To Consider When Purchasing A Steel Coil Packing LineTop 6 things To Consider When making an investment in an automatic steel coil packing line, one of the primary considerations must be the types and sizes of steel coils it will be designed to package. Factors like the packaging method, stacking approach, and strapping options are all directly influenced by the dimensional charact...

-

Benefits of Switching Manual to Automated PackagingBenefits of Switching to Automated Packaging In every busy warehouse, the end of line packaging operation plays a crucial role in meeting the needs of today's fast-paced commerce. Your secondary packaging process is essential for moving products quickly and safely through the supply chain. However, this process is changing rapidl...

-

The spare part list of the coil wrapping machineList of Standard spare part Description Brand Quantity Picture Tension adjusting spring FHOPE 2Pcs Bearing FHOPE 2pcs Small ring wheel FHOPE 4pcs Big ring wheel FHOPE 4pcs Air Pipe Connector FHOPE 2pcs Tool box with tools FHOPE 1 set Listof suggested spare part...

-

After Sale Service for the coil wrapping machineOnline Training Service We provide comprehensive support for your steel coil wrapping machine, including: • Training videos and user manuals in English covering installation, operation, maintenance, and troubleshooting. • Technical assistance through various channels: remote desktop support, email, phone, mobile, WhatsApp, an...

-

General Safety Rules In Operation1 GENERAL SAFETY RULES WARNING! Read all instructions. Failure to follow all instructions listed below may result in electric shock, fire and/ or serious injury. The term Wrapping machine in all of the warnings listed below refers to your mains operated (corded) Wrapping machine or battery operated (cordless) Wrapping machine. SA...

-

Safety rules for strapping tools operationSAFETY RULES FOR STRAPPING TOOLS 1Joints You are fully responsible to review the joints made by your tool. Become familiar with the seal control and seal adjustment described in this operation manual. Misformed joints may not secure the load and could cause serious injury. Never handle or ship any load with improperly formed join...

Understanding the Pricing Structure for Steel Coil Packing Lines

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How Our Installation and Support Services Ensure Minimal Downtime for Your Steel Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

The Importance of Equipment Testing and Commissioning for Steel Coil Packing Lines

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to Get the Most Out of Your Steel Coil Packing Line Through Proper Training

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Semi-Automatic and Fully Automatic Steel Coil Packing Lines Difference

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Top Coil Wrapping Line Manufacturer

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Automated Coil Strapping and Packing Line: Boost Efficiency and Reduce Labor by 90%

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Turnkey Solution: Fully Automated Coil Slitting and Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to prevent coils being picked up missed together in coil packing line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Metal Coil Strapping And Packing Line In Colombia

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Guide of the Coil Car for Integrating the Coil Rewinder with Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Automatic copper slitting coil strip packaging line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Capacity of The Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Way To Know Coil packing line price By Yourself

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Technical The Best Coil Packing Line Should Included

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What is Crucial in Steel Coil Packaging Line Integrations

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What after service you will have for Copper strip packing line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Technical Efficiency for Slit Coil Packaging Systems

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to measure the technical efficiency for steel coil strapping line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Guide to Optimizing Operational Expenditures For Steel Coil Strapping And Stacking Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Understanding the Pricing Structure for Steel Coil Packing Lines

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How Our Installation and Support Services Ensure Minimal Downtime for Your Steel Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

The Importance of Equipment Testing and Commissioning for Steel Coil Packing Lines

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to Get the Most Out of Your Steel Coil Packing Line Through Proper Training

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Semi-Automatic and Fully Automatic Steel Coil Packing Lines Difference

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Top Coil Wrapping Line Manufacturer

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Automated Coil Strapping and Packing Line: Boost Efficiency and Reduce Labor by 90%

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Turnkey Solution: Fully Automated Coil Slitting and Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to prevent coils being picked up missed together in coil packing line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Metal Coil Strapping And Packing Line In Colombia

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Guide of the Coil Car for Integrating the Coil Rewinder with Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Automatic copper slitting coil strip packaging line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Capacity of The Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Way To Know Coil packing line price By Yourself

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Technical The Best Coil Packing Line Should Included

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What is Crucial in Steel Coil Packaging Line Integrations

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What after service you will have for Copper strip packing line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Technical Efficiency for Slit Coil Packaging Systems

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to measure the technical efficiency for steel coil strapping line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Guide to Optimizing Operational Expenditures For Steel Coil Strapping And Stacking Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Understanding the Pricing Structure for Steel Coil Packing Lines

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How Our Installation and Support Services Ensure Minimal Downtime for Your Steel Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

The Importance of Equipment Testing and Commissioning for Steel Coil Packing Lines

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to Get the Most Out of Your Steel Coil Packing Line Through Proper Training

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Semi-Automatic and Fully Automatic Steel Coil Packing Lines Difference

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Top Coil Wrapping Line Manufacturer

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Automated Coil Strapping and Packing Line: Boost Efficiency and Reduce Labor by 90%

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Turnkey Solution: Fully Automated Coil Slitting and Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to prevent coils being picked up missed together in coil packing line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Metal Coil Strapping And Packing Line In Colombia

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Guide of the Coil Car for Integrating the Coil Rewinder with Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Automatic copper slitting coil strip packaging line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Capacity of The Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Way To Know Coil packing line price By Yourself

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Technical The Best Coil Packing Line Should Included

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What is Crucial in Steel Coil Packaging Line Integrations

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What after service you will have for Copper strip packing line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Technical Efficiency for Slit Coil Packaging Systems

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to measure the technical efficiency for steel coil strapping line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Guide to Optimizing Operational Expenditures For Steel Coil Strapping And Stacking Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Understanding the Pricing Structure for Steel Coil Packing Lines

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How Our Installation and Support Services Ensure Minimal Downtime for Your Steel Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

The Importance of Equipment Testing and Commissioning for Steel Coil Packing Lines

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to Get the Most Out of Your Steel Coil Packing Line Through Proper Training

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Semi-Automatic and Fully Automatic Steel Coil Packing Lines Difference

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Top Coil Wrapping Line Manufacturer

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Automated Coil Strapping and Packing Line: Boost Efficiency and Reduce Labor by 90%

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Turnkey Solution: Fully Automated Coil Slitting and Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to prevent coils being picked up missed together in coil packing line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Metal Coil Strapping And Packing Line In Colombia

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Guide of the Coil Car for Integrating the Coil Rewinder with Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Automatic copper slitting coil strip packaging line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Capacity of The Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Way To Know Coil packing line price By Yourself

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Technical The Best Coil Packing Line Should Included

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What is Crucial in Steel Coil Packaging Line Integrations

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What after service you will have for Copper strip packing line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Technical Efficiency for Slit Coil Packaging Systems

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to measure the technical efficiency for steel coil strapping line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Guide to Optimizing Operational Expenditures For Steel Coil Strapping And Stacking Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Understanding the Pricing Structure for Steel Coil Packing Lines

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How Our Installation and Support Services Ensure Minimal Downtime for Your Steel Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

The Importance of Equipment Testing and Commissioning for Steel Coil Packing Lines

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to Get the Most Out of Your Steel Coil Packing Line Through Proper Training

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Semi-Automatic and Fully Automatic Steel Coil Packing Lines Difference

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Top Coil Wrapping Line Manufacturer

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Automated Coil Strapping and Packing Line: Boost Efficiency and Reduce Labor by 90%

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Turnkey Solution: Fully Automated Coil Slitting and Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to prevent coils being picked up missed together in coil packing line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Metal Coil Strapping And Packing Line In Colombia

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Guide of the Coil Car for Integrating the Coil Rewinder with Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Automatic copper slitting coil strip packaging line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Capacity of The Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Way To Know Coil packing line price By Yourself

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Technical The Best Coil Packing Line Should Included

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What is Crucial in Steel Coil Packaging Line Integrations

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What after service you will have for Copper strip packing line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Technical Efficiency for Slit Coil Packaging Systems

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to measure the technical efficiency for steel coil strapping line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Guide to Optimizing Operational Expenditures For Steel Coil Strapping And Stacking Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Understanding the Pricing Structure for Steel Coil Packing Lines

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How Our Installation and Support Services Ensure Minimal Downtime for Your Steel Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

The Importance of Equipment Testing and Commissioning for Steel Coil Packing Lines

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to Get the Most Out of Your Steel Coil Packing Line Through Proper Training

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Semi-Automatic and Fully Automatic Steel Coil Packing Lines Difference

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Top Coil Wrapping Line Manufacturer

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Automated Coil Strapping and Packing Line: Boost Efficiency and Reduce Labor by 90%

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Turnkey Solution: Fully Automated Coil Slitting and Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to prevent coils being picked up missed together in coil packing line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Metal Coil Strapping And Packing Line In Colombia

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Guide of the Coil Car for Integrating the Coil Rewinder with Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Automatic copper slitting coil strip packaging line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Capacity of The Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Way To Know Coil packing line price By Yourself

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Technical The Best Coil Packing Line Should Included

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What is Crucial in Steel Coil Packaging Line Integrations

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What after service you will have for Copper strip packing line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Technical Efficiency for Slit Coil Packaging Systems

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to measure the technical efficiency for steel coil strapping line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Guide to Optimizing Operational Expenditures For Steel Coil Strapping And Stacking Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Understanding the Pricing Structure for Steel Coil Packing Lines

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How Our Installation and Support Services Ensure Minimal Downtime for Your Steel Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

The Importance of Equipment Testing and Commissioning for Steel Coil Packing Lines

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to Get the Most Out of Your Steel Coil Packing Line Through Proper Training

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Semi-Automatic and Fully Automatic Steel Coil Packing Lines Difference

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Top Coil Wrapping Line Manufacturer

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Automated Coil Strapping and Packing Line: Boost Efficiency and Reduce Labor by 90%

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Turnkey Solution: Fully Automated Coil Slitting and Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to prevent coils being picked up missed together in coil packing line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Metal Coil Strapping And Packing Line In Colombia

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Guide of the Coil Car for Integrating the Coil Rewinder with Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Automatic copper slitting coil strip packaging line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Capacity of The Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Way To Know Coil packing line price By Yourself

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Technical The Best Coil Packing Line Should Included

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What is Crucial in Steel Coil Packaging Line Integrations

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What after service you will have for Copper strip packing line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Technical Efficiency for Slit Coil Packaging Systems

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to measure the technical efficiency for steel coil strapping line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Guide to Optimizing Operational Expenditures For Steel Coil Strapping And Stacking Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Understanding the Pricing Structure for Steel Coil Packing Lines

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How Our Installation and Support Services Ensure Minimal Downtime for Your Steel Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

The Importance of Equipment Testing and Commissioning for Steel Coil Packing Lines

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to Get the Most Out of Your Steel Coil Packing Line Through Proper Training

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Semi-Automatic and Fully Automatic Steel Coil Packing Lines Difference

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Top Coil Wrapping Line Manufacturer

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Automated Coil Strapping and Packing Line: Boost Efficiency and Reduce Labor by 90%

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Turnkey Solution: Fully Automated Coil Slitting and Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to prevent coils being picked up missed together in coil packing line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Metal Coil Strapping And Packing Line In Colombia

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Guide of the Coil Car for Integrating the Coil Rewinder with Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Automatic copper slitting coil strip packaging line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Capacity of The Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Way To Know Coil packing line price By Yourself

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Technical The Best Coil Packing Line Should Included

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What is Crucial in Steel Coil Packaging Line Integrations

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What after service you will have for Copper strip packing line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Technical Efficiency for Slit Coil Packaging Systems

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to measure the technical efficiency for steel coil strapping line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Guide to Optimizing Operational Expenditures For Steel Coil Strapping And Stacking Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Understanding the Pricing Structure for Steel Coil Packing Lines

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How Our Installation and Support Services Ensure Minimal Downtime for Your Steel Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

The Importance of Equipment Testing and Commissioning for Steel Coil Packing Lines

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to Get the Most Out of Your Steel Coil Packing Line Through Proper Training

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Semi-Automatic and Fully Automatic Steel Coil Packing Lines Difference

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Top Coil Wrapping Line Manufacturer

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Automated Coil Strapping and Packing Line: Boost Efficiency and Reduce Labor by 90%

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Turnkey Solution: Fully Automated Coil Slitting and Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to prevent coils being picked up missed together in coil packing line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Metal Coil Strapping And Packing Line In Colombia

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Guide of the Coil Car for Integrating the Coil Rewinder with Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Automatic copper slitting coil strip packaging line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Capacity of The Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Way To Know Coil packing line price By Yourself

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Technical The Best Coil Packing Line Should Included

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What is Crucial in Steel Coil Packaging Line Integrations

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What after service you will have for Copper strip packing line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Technical Efficiency for Slit Coil Packaging Systems

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to measure the technical efficiency for steel coil strapping line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Guide to Optimizing Operational Expenditures For Steel Coil Strapping And Stacking Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Understanding the Pricing Structure for Steel Coil Packing Lines

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How Our Installation and Support Services Ensure Minimal Downtime for Your Steel Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

The Importance of Equipment Testing and Commissioning for Steel Coil Packing Lines

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to Get the Most Out of Your Steel Coil Packing Line Through Proper Training

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Semi-Automatic and Fully Automatic Steel Coil Packing Lines Difference

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Top Coil Wrapping Line Manufacturer

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Automated Coil Strapping and Packing Line: Boost Efficiency and Reduce Labor by 90%

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Turnkey Solution: Fully Automated Coil Slitting and Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to prevent coils being picked up missed together in coil packing line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Metal Coil Strapping And Packing Line In Colombia

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Guide of the Coil Car for Integrating the Coil Rewinder with Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Automatic copper slitting coil strip packaging line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Capacity of The Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Way To Know Coil packing line price By Yourself

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Technical The Best Coil Packing Line Should Included

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What is Crucial in Steel Coil Packaging Line Integrations

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What after service you will have for Copper strip packing line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Technical Efficiency for Slit Coil Packaging Systems

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to measure the technical efficiency for steel coil strapping line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Guide to Optimizing Operational Expenditures For Steel Coil Strapping And Stacking Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Understanding the Pricing Structure for Steel Coil Packing Lines

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How Our Installation and Support Services Ensure Minimal Downtime for Your Steel Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

The Importance of Equipment Testing and Commissioning for Steel Coil Packing Lines

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to Get the Most Out of Your Steel Coil Packing Line Through Proper Training

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Semi-Automatic and Fully Automatic Steel Coil Packing Lines Difference

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Top Coil Wrapping Line Manufacturer

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Automated Coil Strapping and Packing Line: Boost Efficiency and Reduce Labor by 90%

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Turnkey Solution: Fully Automated Coil Slitting and Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to prevent coils being picked up missed together in coil packing line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Metal Coil Strapping And Packing Line In Colombia

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Guide of the Coil Car for Integrating the Coil Rewinder with Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Automatic copper slitting coil strip packaging line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Capacity of The Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Way To Know Coil packing line price By Yourself

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Technical The Best Coil Packing Line Should Included

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What is Crucial in Steel Coil Packaging Line Integrations

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What after service you will have for Copper strip packing line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Technical Efficiency for Slit Coil Packaging Systems

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to measure the technical efficiency for steel coil strapping line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Guide to Optimizing Operational Expenditures For Steel Coil Strapping And Stacking Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Understanding the Pricing Structure for Steel Coil Packing Lines

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How Our Installation and Support Services Ensure Minimal Downtime for Your Steel Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

The Importance of Equipment Testing and Commissioning for Steel Coil Packing Lines

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to Get the Most Out of Your Steel Coil Packing Line Through Proper Training

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Semi-Automatic and Fully Automatic Steel Coil Packing Lines Difference

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Top Coil Wrapping Line Manufacturer

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Automated Coil Strapping and Packing Line: Boost Efficiency and Reduce Labor by 90%

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Turnkey Solution: Fully Automated Coil Slitting and Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to prevent coils being picked up missed together in coil packing line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Metal Coil Strapping And Packing Line In Colombia

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Guide of the Coil Car for Integrating the Coil Rewinder with Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Automatic copper slitting coil strip packaging line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Capacity of The Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Way To Know Coil packing line price By Yourself

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Technical The Best Coil Packing Line Should Included

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What is Crucial in Steel Coil Packaging Line Integrations

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What after service you will have for Copper strip packing line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Technical Efficiency for Slit Coil Packaging Systems

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to measure the technical efficiency for steel coil strapping line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Guide to Optimizing Operational Expenditures For Steel Coil Strapping And Stacking Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Understanding the Pricing Structure for Steel Coil Packing Lines

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How Our Installation and Support Services Ensure Minimal Downtime for Your Steel Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

The Importance of Equipment Testing and Commissioning for Steel Coil Packing Lines

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to Get the Most Out of Your Steel Coil Packing Line Through Proper Training

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Semi-Automatic and Fully Automatic Steel Coil Packing Lines Difference

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Top Coil Wrapping Line Manufacturer

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Automated Coil Strapping and Packing Line: Boost Efficiency and Reduce Labor by 90%

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Turnkey Solution: Fully Automated Coil Slitting and Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to prevent coils being picked up missed together in coil packing line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Metal Coil Strapping And Packing Line In Colombia

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Guide of the Coil Car for Integrating the Coil Rewinder with Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Automatic copper slitting coil strip packaging line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Capacity of The Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Way To Know Coil packing line price By Yourself

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Technical The Best Coil Packing Line Should Included

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What is Crucial in Steel Coil Packaging Line Integrations

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What after service you will have for Copper strip packing line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Technical Efficiency for Slit Coil Packaging Systems

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to measure the technical efficiency for steel coil strapping line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Guide to Optimizing Operational Expenditures For Steel Coil Strapping And Stacking Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Understanding the Pricing Structure for Steel Coil Packing Lines

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How Our Installation and Support Services Ensure Minimal Downtime for Your Steel Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

The Importance of Equipment Testing and Commissioning for Steel Coil Packing Lines

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to Get the Most Out of Your Steel Coil Packing Line Through Proper Training

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Semi-Automatic and Fully Automatic Steel Coil Packing Lines Difference

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Top Coil Wrapping Line Manufacturer

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Automated Coil Strapping and Packing Line: Boost Efficiency and Reduce Labor by 90%

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Turnkey Solution: Fully Automated Coil Slitting and Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to prevent coils being picked up missed together in coil packing line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Metal Coil Strapping And Packing Line In Colombia

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Guide of the Coil Car for Integrating the Coil Rewinder with Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Automatic copper slitting coil strip packaging line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Capacity of The Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Way To Know Coil packing line price By Yourself

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Technical The Best Coil Packing Line Should Included

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What is Crucial in Steel Coil Packaging Line Integrations

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What after service you will have for Copper strip packing line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Technical Efficiency for Slit Coil Packaging Systems

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to measure the technical efficiency for steel coil strapping line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Guide to Optimizing Operational Expenditures For Steel Coil Strapping And Stacking Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Understanding the Pricing Structure for Steel Coil Packing Lines

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How Our Installation and Support Services Ensure Minimal Downtime for Your Steel Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

The Importance of Equipment Testing and Commissioning for Steel Coil Packing Lines

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to Get the Most Out of Your Steel Coil Packing Line Through Proper Training

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Semi-Automatic and Fully Automatic Steel Coil Packing Lines Difference

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Top Coil Wrapping Line Manufacturer

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Automated Coil Strapping and Packing Line: Boost Efficiency and Reduce Labor by 90%

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Turnkey Solution: Fully Automated Coil Slitting and Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to prevent coils being picked up missed together in coil packing line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Metal Coil Strapping And Packing Line In Colombia

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Guide of the Coil Car for Integrating the Coil Rewinder with Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Automatic copper slitting coil strip packaging line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Capacity of The Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Way To Know Coil packing line price By Yourself

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Technical The Best Coil Packing Line Should Included

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What is Crucial in Steel Coil Packaging Line Integrations

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What after service you will have for Copper strip packing line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Technical Efficiency for Slit Coil Packaging Systems

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to measure the technical efficiency for steel coil strapping line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Guide to Optimizing Operational Expenditures For Steel Coil Strapping And Stacking Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Understanding the Pricing Structure for Steel Coil Packing Lines

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How Our Installation and Support Services Ensure Minimal Downtime for Your Steel Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

The Importance of Equipment Testing and Commissioning for Steel Coil Packing Lines

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to Get the Most Out of Your Steel Coil Packing Line Through Proper Training

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Semi-Automatic and Fully Automatic Steel Coil Packing Lines Difference

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Top Coil Wrapping Line Manufacturer

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Automated Coil Strapping and Packing Line: Boost Efficiency and Reduce Labor by 90%

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Turnkey Solution: Fully Automated Coil Slitting and Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to prevent coils being picked up missed together in coil packing line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Metal Coil Strapping And Packing Line In Colombia

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Guide of the Coil Car for Integrating the Coil Rewinder with Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Automatic copper slitting coil strip packaging line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Capacity of The Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Way To Know Coil packing line price By Yourself

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Technical The Best Coil Packing Line Should Included

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What is Crucial in Steel Coil Packaging Line Integrations

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What after service you will have for Copper strip packing line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Technical Efficiency for Slit Coil Packaging Systems

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to measure the technical efficiency for steel coil strapping line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Guide to Optimizing Operational Expenditures For Steel Coil Strapping And Stacking Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Understanding the Pricing Structure for Steel Coil Packing Lines

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How Our Installation and Support Services Ensure Minimal Downtime for Your Steel Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

The Importance of Equipment Testing and Commissioning for Steel Coil Packing Lines

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to Get the Most Out of Your Steel Coil Packing Line Through Proper Training

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Semi-Automatic and Fully Automatic Steel Coil Packing Lines Difference

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Top Coil Wrapping Line Manufacturer

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Automated Coil Strapping and Packing Line: Boost Efficiency and Reduce Labor by 90%

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Turnkey Solution: Fully Automated Coil Slitting and Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to prevent coils being picked up missed together in coil packing line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Metal Coil Strapping And Packing Line In Colombia

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Guide of the Coil Car for Integrating the Coil Rewinder with Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Automatic copper slitting coil strip packaging line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Capacity of The Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Way To Know Coil packing line price By Yourself

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Technical The Best Coil Packing Line Should Included

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What is Crucial in Steel Coil Packaging Line Integrations

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What after service you will have for Copper strip packing line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Technical Efficiency for Slit Coil Packaging Systems

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to measure the technical efficiency for steel coil strapping line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Guide to Optimizing Operational Expenditures For Steel Coil Strapping And Stacking Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Understanding the Pricing Structure for Steel Coil Packing Lines

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How Our Installation and Support Services Ensure Minimal Downtime for Your Steel Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

The Importance of Equipment Testing and Commissioning for Steel Coil Packing Lines

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to Get the Most Out of Your Steel Coil Packing Line Through Proper Training

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Semi-Automatic and Fully Automatic Steel Coil Packing Lines Difference

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Top Coil Wrapping Line Manufacturer

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Automated Coil Strapping and Packing Line: Boost Efficiency and Reduce Labor by 90%

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Turnkey Solution: Fully Automated Coil Slitting and Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to prevent coils being picked up missed together in coil packing line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Metal Coil Strapping And Packing Line In Colombia

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Guide of the Coil Car for Integrating the Coil Rewinder with Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Automatic copper slitting coil strip packaging line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Capacity of The Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Way To Know Coil packing line price By Yourself

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Technical The Best Coil Packing Line Should Included

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What is Crucial in Steel Coil Packaging Line Integrations

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What after service you will have for Copper strip packing line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Technical Efficiency for Slit Coil Packaging Systems

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to measure the technical efficiency for steel coil strapping line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Guide to Optimizing Operational Expenditures For Steel Coil Strapping And Stacking Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Understanding the Pricing Structure for Steel Coil Packing Lines

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How Our Installation and Support Services Ensure Minimal Downtime for Your Steel Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

The Importance of Equipment Testing and Commissioning for Steel Coil Packing Lines

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to Get the Most Out of Your Steel Coil Packing Line Through Proper Training

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Semi-Automatic and Fully Automatic Steel Coil Packing Lines Difference

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Top Coil Wrapping Line Manufacturer

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Automated Coil Strapping and Packing Line: Boost Efficiency and Reduce Labor by 90%

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Turnkey Solution: Fully Automated Coil Slitting and Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

How to prevent coils being picked up missed together in coil packing line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Metal Coil Strapping And Packing Line In Colombia

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Guide of the Coil Car for Integrating the Coil Rewinder with Coil Packing Line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

Automatic copper slitting coil strip packaging line

Highly efficient, automated system for wrapping and securing heavy metal products for safe transport.

Learn More

What Is The Capacity of The Coil Packing Line