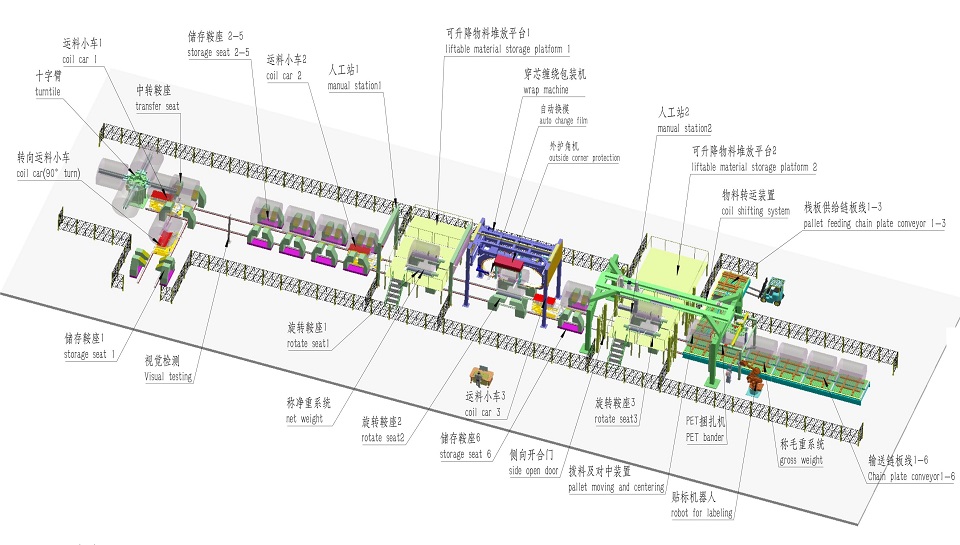

What Is The Capacity of The Coil Packing Line

The coil packing line is available in a range of sizes to cater to various packaging needs. The line offers adjustable parameters that can be tailored to accommodate different dimensions and specifications. Function: coil unloading from rewinder of the slitting line

The line can unload up to 1000 tons of coils per week. The coil weights range from 1 to 5 tons each, and the unloading speed is 20-30 coils per hour. The coils are automatically transferred from the slitting line to the next process via a track transfer system.

coil transfer to the turnstile

The turnstile can handle 2-4 coils simultaneously. When a coil is unloaded from the track, the turnstile uses servomotors to precisely rotate and move the coil to the next handling point via an automated process.

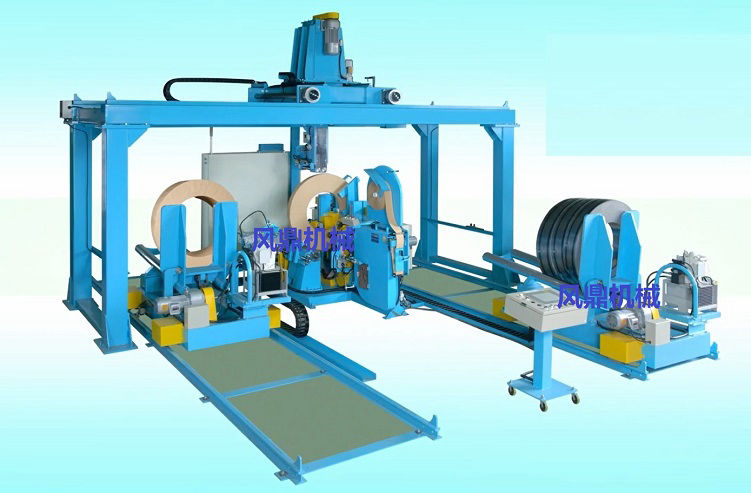

coil strapping on turnstile

On the turnstile, a strapping machine uses a movable arm to automatically apply strapping material tightly around the coils within 5-8 seconds, securely wrapping each coil.

coil separating and pick up from turnstile,

Once stripped from the turnstile, an overhead crane precisely lifts and transfers the coils to the next processing stage. The coils remain well protected during the lifting and movement process to prevent damage or deformation.

Coil 90- degree turning

The line can rotate coils 90 degrees using an automatic turntable for applications requiring angle changes to the coils. Pneumatic grippers gently grip each coil and precisely rotate them in under 15 seconds.

coil moving,

After rotating, powered belt conveyors rapidly but smoothly transport

coils to subsequent areas. sensors and PLC controls ensure coils are

shifted exactly where needed for wrapping or stacking.

coil wrapping,

An automated wrapping machine uses rotary arms and programmable controls

to wrap heavy-duty stretch film tightly around each coil in less than

30 seconds. Film rollers and servo drives ensure a professional

appearance.

coil eye through strapping

An eye bolting assembly inserts a steel rod through the center of select

coils, allowing them to be lifted or secured via the coil eye. A

strapping head then applies narrow steel strapping around coil and bolt

for additional stability.

coil stacking with timber

Coils can be stacked up to 5 high on timber frames, securely banded

together. Pre-cut timbers are automatically inserted, maximizing floor

space usage during storage and shipment.

coil pallet wrapping

Once banded and wrapped, coils are robotically placed onto pallets, then

a wrapping machine stretches transparent film all around, fully

enclosing the load. Pallets can be comfortably stacked up to 3 high for

warehouse storage or trucking.

coil pallet strapping

Industrial coil strapping is applied around pallet loads, adding further

strength. Self-tensioning strapping heads pull straps to desired

tautness without risk of overtightening.

coil pallet wrapping.

The finished palletized loads are clearly labeled with barcodes, ready

for shipping. Stretch wrapping creates a protective barrier from dust

and moisture during transport.

WHY CHOOSE FHOPE FOR COIL PACKING SYSTEM

-

Safety: FHOPE packing line prioritize user safety with built-in CE protective features..

-

Uptime: Our packing line solutions adapt to any load and speed, ensuring continuous, jam-free operation..

-

Easy to use: user-friendly, requiring minimal training and maintenance, and consistently delivers quality and efficiency.

-

Performance: leads the industry with 15+ years of innovative, updateing technology for coil packing.

-

24/7 support:unparalleled 24/7 support and service, best-in-class warranty.

-

Automation: Programing and system connection from Level 1, level 2, level 3.

THE SPECIFICATION OF THE COIL FOR INDIAN SERVICE CENTER FOR REFERENCE:

-

Coil Width: Common steel coil widths can range from 600mm to 2000mm or more, depending on the specific application and industry requirements.

-

Coil Outer Diameter: Steel coils typically have an outer diameter ranging from 1000mm to 2200mm, although larger sizes may also be used for specific applications.

-

Coil Inner Diameter: The inner diameter of steel coils is commonly standardized at 508mm (20 inches) or 610mm (24 inches), although other sizes may be used based on customer specifications.

-

Coil Weight: Steel coil weights vary widely depending on the thickness and width of the material. Common steel coil weights can range from a few hundred kilograms to several metric tons, such as 3-5 tons or even higher.

-

Coil Thickness: Steel coils come in various thicknesses, typically ranging from 0.5mm to 10mm or more, depending on the specific steel grade and application.

RELATIVE APPLICATION:

Brass processing

-

By employing coil packing line sizes for strapping and sealing brass bars, manufacturers can achieve several significant benefits. Firstly, the automated strapping process ensures that the bars are securely bundled and tightly sealed, preventing any potential deformation or shifting during handling and storage. This helps maintain the structural integrity and dimensional accuracy of the brass bars, reducing the need for rework or quality issues. Moreover, the uniform tension applied during strapping helps distribute the load evenly across the bundled bars, ensuring stability and minimizing the risk of damage. Additionally, the standardized coil packing line sizes enable efficient and streamlined logistics, simplifying loading and unloading operations, and minimizing handling time. This contributes to improved operational efficiency and customer satisfaction. Ultimately, the utilization of coil packing line sizes in strapping and sealing brass bars offers enhanced product protection, optimized logistics, and reduced handling-related risks, benefiting manufacturers in the brass industry.

Accurate and dependable packing system

Coil packing line sizes are essential when it comes to packaging copper coils for efficient space utilization in warehouses. Through automated packaging, the copper coils are wrapped precisely and securely sealed, minimizing the chances of tangling or damage during handling and storage.Optimized packaging minimizes wasted space by employing coil packing line sizes that are tailored to the dimensions of the copper coils, including inner and outer diameters, width, and thickness.Standardized packaging simplifies the identification and retrieval of specific coil sizes, streamlining inventory management and reducing search time.Enhanced space utilization and streamlined operations lead to reduced storage costs, improved efficiency, and ultimately, increased overall productivity in manufacturers' copper coil handling processes.Coil packing line sizes provide considerable benefits in the strapping and bundling of plastic film rolls for efficient distribution.