Fhopepack Innovation

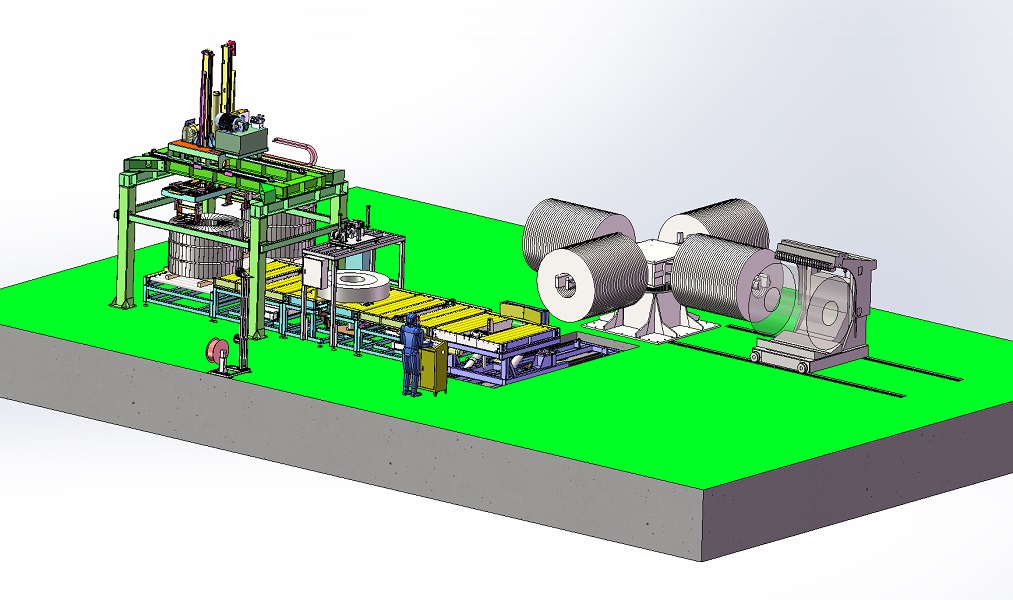

What is Crucial in Steel Coil Packaging Line Integrations

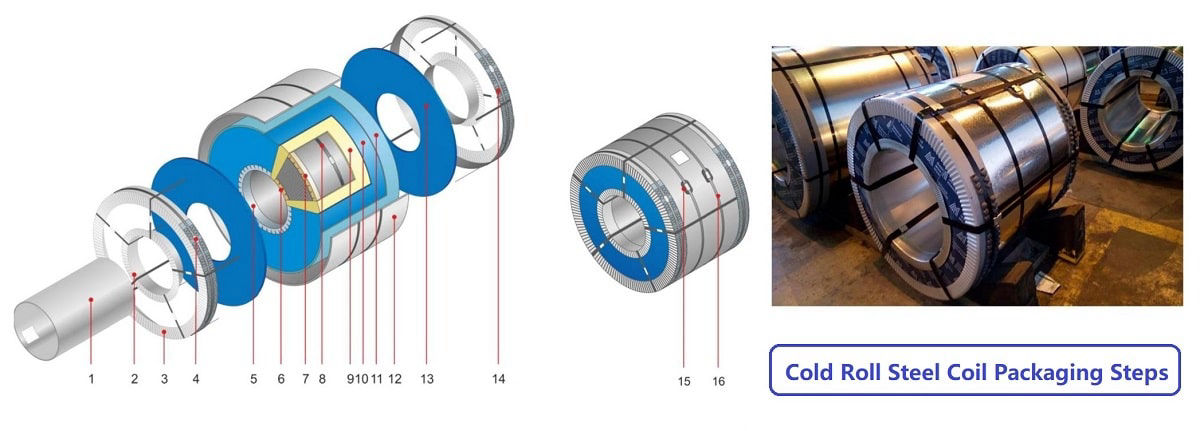

Coil packing line manufacturers Fhope is a specialized manufacturer of coil packaging machinery. We offer a comprehensive range of coil wrapping machines, coil strapping systems, and coil tilter solutions that cater to the specific needs of coil packing , including steel coil packing line. We provide custom-built coil packaging systems that incorporate stretch wrapping, strapping, and labeling cap