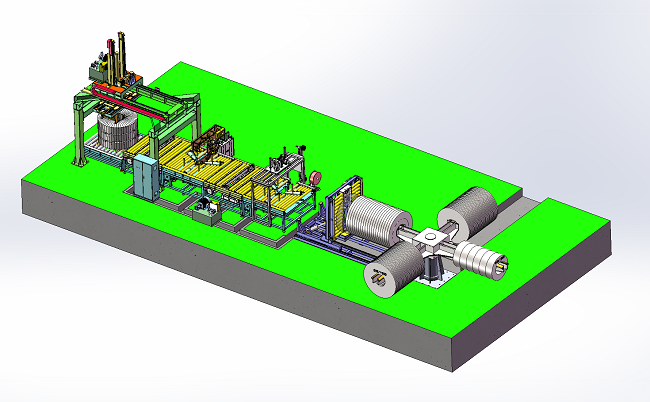

Slit coil handling and packaging line

The full range of the slit coil handling and packing line available in economical, automatic/manually operation with PC controller.

The packing line is able connect to the slitting line and picking up coil from turnstile arm.

Automatic strapping machines and allow strapping the coil through ID coil tail.

And stacked the coils on a skid for storage and shipment

The packing and handling system for the slitting coil:

a. increasing the coil handling and packing speed.

b. Protecting the products surface and reduce damage.

c. Saves the man power.

d. Reduce the maintenance time and cost.

In this system the non-ferrous coils can be wrapped in the plastic stretch film for dust, moisture protection.

Base on the user friendly designing the coils an be tracking in the packing, weighing, labeling for shop and stock control system.

Main part of the slitting col handling and packing line:

1. Coil Down Ender

The coil down ender system efficiently lifts individual bare coils from a turnstile, transferring them to a conveyor. This setup comprises a hydraulic station, coil lifter, and conveyor, ensuring smooth and reliable handling of coils throughout the process.

2. Steel Coil Strapping Machine

The automated PET strapping machine for steel coils is designed for eye-through strapping. Capable of elevating and rotating the coil 360 degrees, it ensures precise and secure strapping with options for 3, 4, or 6 straps, enhancing efficiency and consistency in the packaging process.

3. Slit Coil Packing Machine

This fully automatic coil packing machine is specifically engineered for wrapping steel coils with paper and stretch film through the eye of the coil. Streamlining the packaging process, it efficiently and securely wraps steel coils, ensuring consistent and reliable protection throughout handling and transportation.

4. Centering Station

The Centering Station features a roller conveyor and lifting table designed to guide and center steel coils efficiently. As the coil approaches the station, sensors detect its presence, prompting the roller platform to lift the coil from the conveyor. A centering pushing mechanism then aligns the coil with the conveyor's center, ensuring proper positioning for subsequent processing stages.

5. Slitting Coil Stacking Machine

It is an advanced stacking solution designed to transfer packed coils from the centering conveyor to a pallet, one at a time. This system significantly reduces manual labor involved in handling heavy coils, thereby enhancing safety and efficiency. To further ensure secure stacking, timber separators are manually inserted between each coil, maintaining stability and preventing damage during transport.