This document offers a detailed guide on the operation and settings for the steel wire coil wrapping machine, designed specifically for packaging ring-shaped products such as coils of copper, steel, and aluminum, as well as hoses and wires. It highlights the machine's versatile use across diverse applications, ensuring a broad utility in various industrial settings. The guide places a strong emphasis on the automated control features of the machine, which streamline the packaging process, enhance efficiency, and minimize manual intervention. These features include programmable logic controllers (PLC) for precise operation and various adjustable settings to accommodate different product sizes and packaging materials. This meticulous attention to control mechanisms ensures that the machine can deliver high-quality, consistent packaging results, making it an essential tool for manufacturers dealing with ring-shaped products.

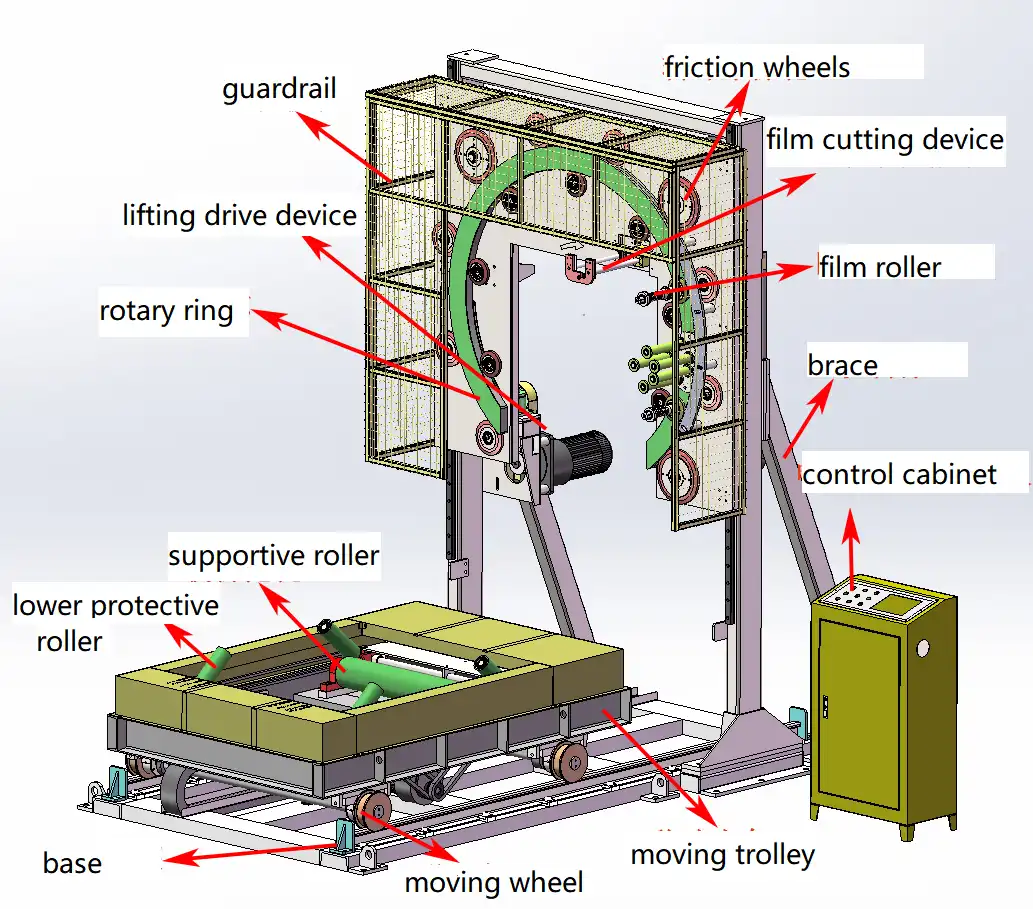

The steel wire coil winding packaging machine is designed for the wrapping and packaging of ring-shaped products. It comes in four main configurations: upward opening, downward opening, host moving, and cart moving. This machine is versatile and used for a wide range of annular products, including copper, steel, aluminum, and alloy strips, as well as copper wire, steel wire, aluminum wire, and coils made from various materials. It can also handle items like iron wire, plastic coils, hoses, stranded wires, and tires.

Primarily, the machine is employed for wrapping and packing steel wire coils, plastic coils, hoses, and tubes. It ensures that the packaged items are relatively sealed, enhancing their appearance and providing protection against water, dust, rust, and wear.

1. Reel Weight: Capable of handling reels weighing between 500 and 3500 kilograms.

2. Packing Material: Utilizes a two-layer synchronous winding technique with internal threading.

3. Material Options: Compatible with LLDPE and PVC.

4. Dimensions for LLDPE/PVC:

- Inner Diameter: 50 mm

- Outer Diameter: 100-150 mm

- Width: 100-120 mm

5. Dimensions for HDPE:

- Inner Diameter: 50 mm

- Outer Diameter: 200-350 mm

- Width: 100-120 mm

Proper configuration of the coil wrapping machine is essential for achieving optimal packaging results. The setup begins with entering the Coil OD, which is the actual outer diameter of the product being packaged. This ensures the machine is calibrated to the correct size.

Adjust the Foil Width to match the packaging material. After changing this setting, remember to modify other parameters to maintain consistency and effectiveness.

The Coefficient acts like an overlap rate, with a standard value of 1.0. If you notice that the packaging material is excessive after a complete wrap, reduce this value incrementally, such as 0.99 or 0.98, to find the best fit.

Number Correction is crucial due to potential errors in the friction drive and rotary ring. This adjustment ensures the material isn't wasted by modifying the number of laps (+1, -1, etc.). It's important to adjust this setting in conjunction with the coefficient for optimal results. For example, if adding a lap results in excess material, adjust the coefficient to 0.95 to slow the roller speed and balance the settings.

The Foil Number by PLC is automatically generated, ensuring precise control over the number of laps during wrapping.

Film Pulling Time is the delay after the final lap, which can be adjusted during initial debugging to ensure smooth operation. Similarly, the Cutting Knife Action Time sets the delay between pulling back the packaging tape and the cutter action, which should also be fine-tuned during setup.

Finally, the Cutting function allows for precise trimming of the woven tape, ensuring clean and efficient packaging. By carefully setting these parameters, the machine can operate smoothly and effectively, minimizing material waste and maximizing efficiency.