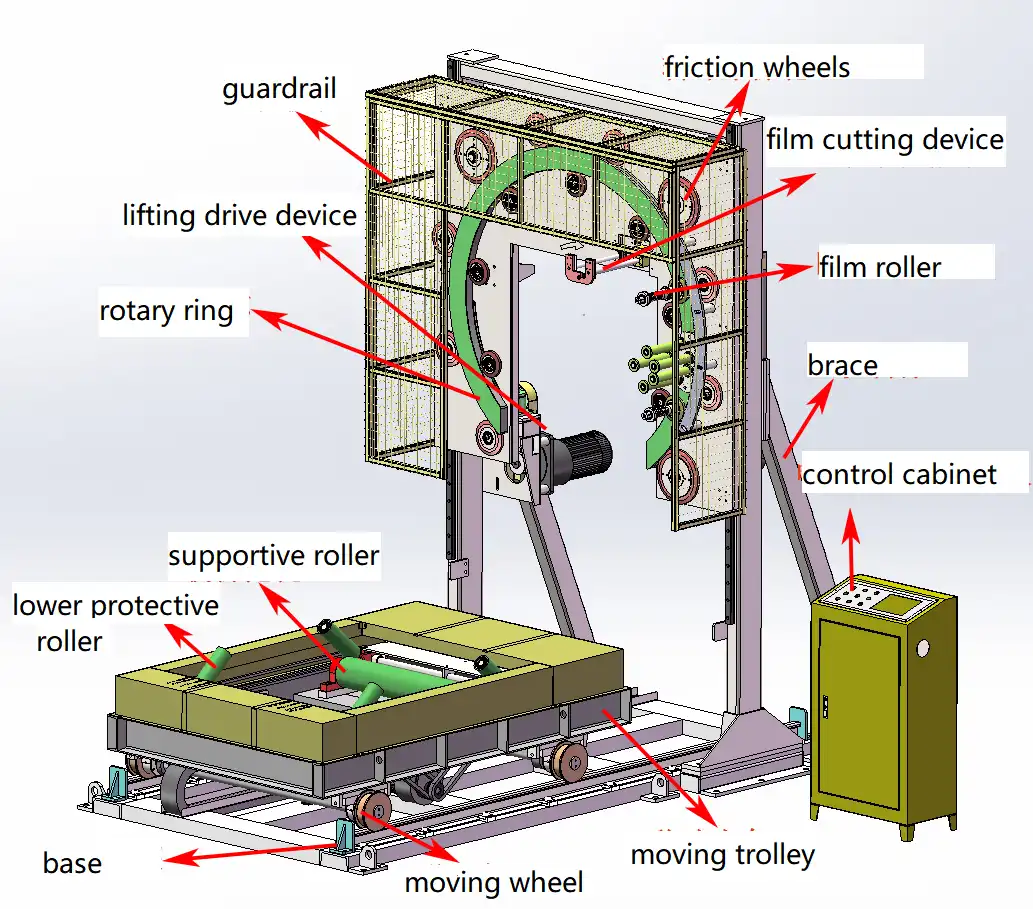

This document offers a detailed guide on the operation and settings for the steel wire coil wrapping machine, designed specifically for packaging ring-shaped products such as coils of copper, steel, and aluminum, as well as hoses and wires. It highlights the machine's versatile use across diverse applications, ensuring a broad utility in various industrial settings. The guide places a strong emphasis on the automated control features of the machine, which streamline the packaging process, enhance efficiency, and minimize manual intervention. These features include programmable logic controllers (PLC) for precise operation and various adjustable settings to accommodate different product sizes and packaging materials. This meticulous attention to control mechanisms ensures that the machine can deliver high-quality, consistent packaging results, making it an essential tool for manufacturers dealing with ring-shaped products.

Hydraulic cylinders are devices that convert fluid pressure into linear motion. It acting like strong arms, hydraulic cylinders use pressurized fluid to push and pull loads, generating back-and-forth or up-and-down motion. They are commonly seen in construction equipment, such as excavators, and in industrial machinery.

Self-contained axes are compact units that integrate cylinders, valves, and sensors. These modular units combine multiple components and are ideal for precise movements in tight spaces. Frequently used in manufacturing and robotics, they allow for efficient, controlled motion in environments with limited room.

Hydraulic motors convert fluid pressure into rotational motion.That are designed to generate continuous rotational force from pressurized fluid, making them perfect for tasks requiring constant spinning, such as driving wheels on heavy vehicles or powering industrial mixers and drills.

Pumps are the core component of hydraulic systems that move fluid through the system to create pressure. As the heart of the system, pumps generate the hydraulic pressure needed to power other components. Depending on the application, pumps vary in type, from small units for light machinery to large pumps for industrial-scale operations.

Pump systems are complex assemblies consisting of pumps, reservoirs, and control valves. Designed for large-scale operations, pump systems offer efficient and reliable fluid power. These systems are often used in heavy machinery where consistent and controlled fluid delivery is required for high-pressure tasks.

Power units are the primary energy sources in hydraulic systems. Typically composed of a motor, pump, reservoir, and control components, power units supply pressurized fluid to the system. This all-in-one package ensures that the system operates efficiently by delivering the necessary energy to drive other components.

Manifolds and plates are components that direct and control fluid flow within the system. Acting like traffic controllers, manifolds and plates manage the pathways through which hydraulic fluid travels, ensuring that it reaches the correct areas of the system to maintain efficient and smooth operation.

Valves regulate the direction, pressure, and flow of hydraulic fluid. Valves are essential for controlling the operation of the hydraulic system. Whether manually or electronically controlled, they ensure that the fluid moves in the correct direction and at the appropriate pressure to achieve desired system performance.

Electronics and control systems provide intelligent management of hydraulic systems. These are the "brains" of modern hydraulic systems, utilizing sensors and computers to monitor and adjust fluid flow. This ensures greater efficiency, precision, and responsiveness in system operations, leading to optimized performance.

Sensors monitor key system parameters such as pressure, temperature, and position. Sensors play a crucial role in ensuring that the hydraulic system operates correctly and safely. By detecting changes in pressure or temperature, sensors can trigger adjustments to maintain system stability and prevent damage.

Accumulators store energy in the form of pressurized fluid. By smoothing out pressure fluctuations, accumulators help maintain a consistent flow of power in the hydraulic system. They also provide extra power during periods of high demand, enhancing the system's efficiency and stability.

The guideline of the coil wrapping machine operation & settin

How to Use and Maintain the Storage Battery for Mobile Pallet