Home > Products > Show Room > Coil Packing Line >

Fhopepack Innovation

Guide to Optimizing Operational Expenditures For Steel Coil Strapping And Stacking Line

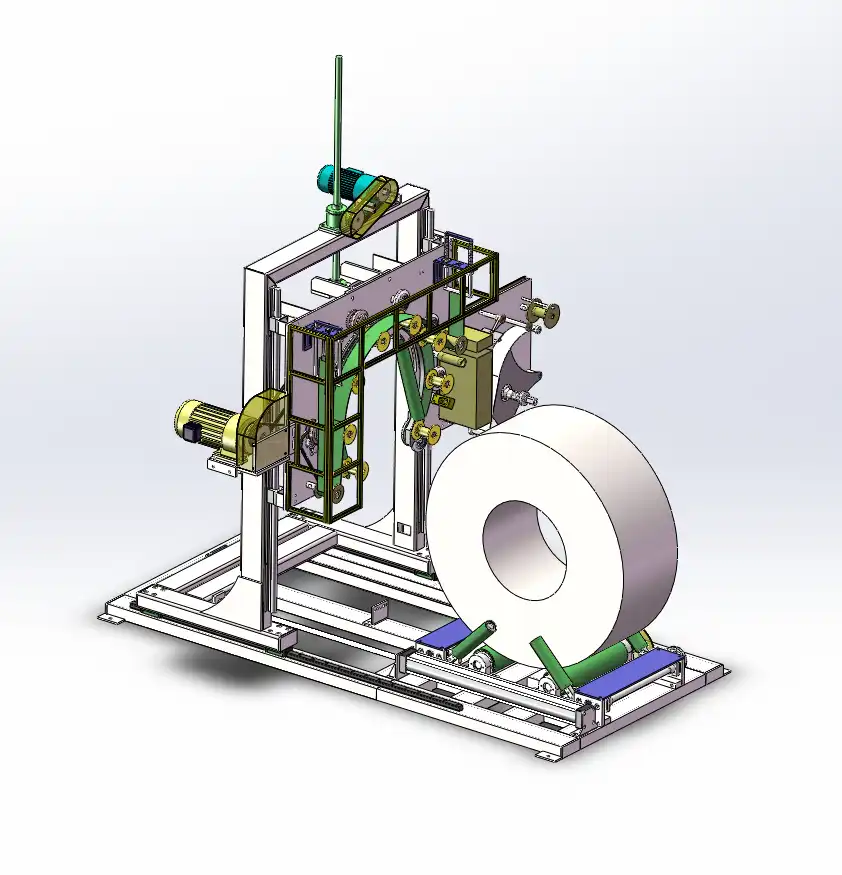

The Steel Coil Strapping and Stacking Line is engineered for efficient handling and secure packaging of steel coils. This automated line ensures precision in strapping and optimal stacking for safe transportation and storage, enhancing operational throughput and reducing labor costs.