Horizontal Stretch Wrapper | Horizontal Stretch Wrapper Manufacturer

To optimize your factory’s packaging operations, the horizontal stretch wrapper offers an efficient and reliable solution. Designed to accommodate long or irregularly shaped items such as pipes, panels, and furniture, this machine ensures consistent film application, protecting goods during transit and storage. Its automation reduces labor costs, enhances productivity, and delivers superior wrapping quality, making it an essential asset for high-volume manufacturing environments. By investing in this technology, businesses can improve efficiency, minimize material waste, and ensure the secure handling of products across various industries.

Semi-Automatic Horizontal Stretch Wrapper

Choosing the right semi-automatic horizontal stretch wrapper designed for improving efficiency in packaging operations while offering flexibility for small to medium-scale production. Key factors to consider include:

- Product Fit: Ensure compatibility with your product's size, shape, and weight.

- Ease of Use: Prioritize simple controls and quick setup.

- Efficiency: Check for consistent wrapping speed and quality.

- Cost Savings: Opt for models minimizing film waste.

- Durability: Choose robust machines for daily industrial use.

- Compact Design: Consider space-saving or mobile options.

A well-chosen wrapper balances efficiency, reliability, and cost.

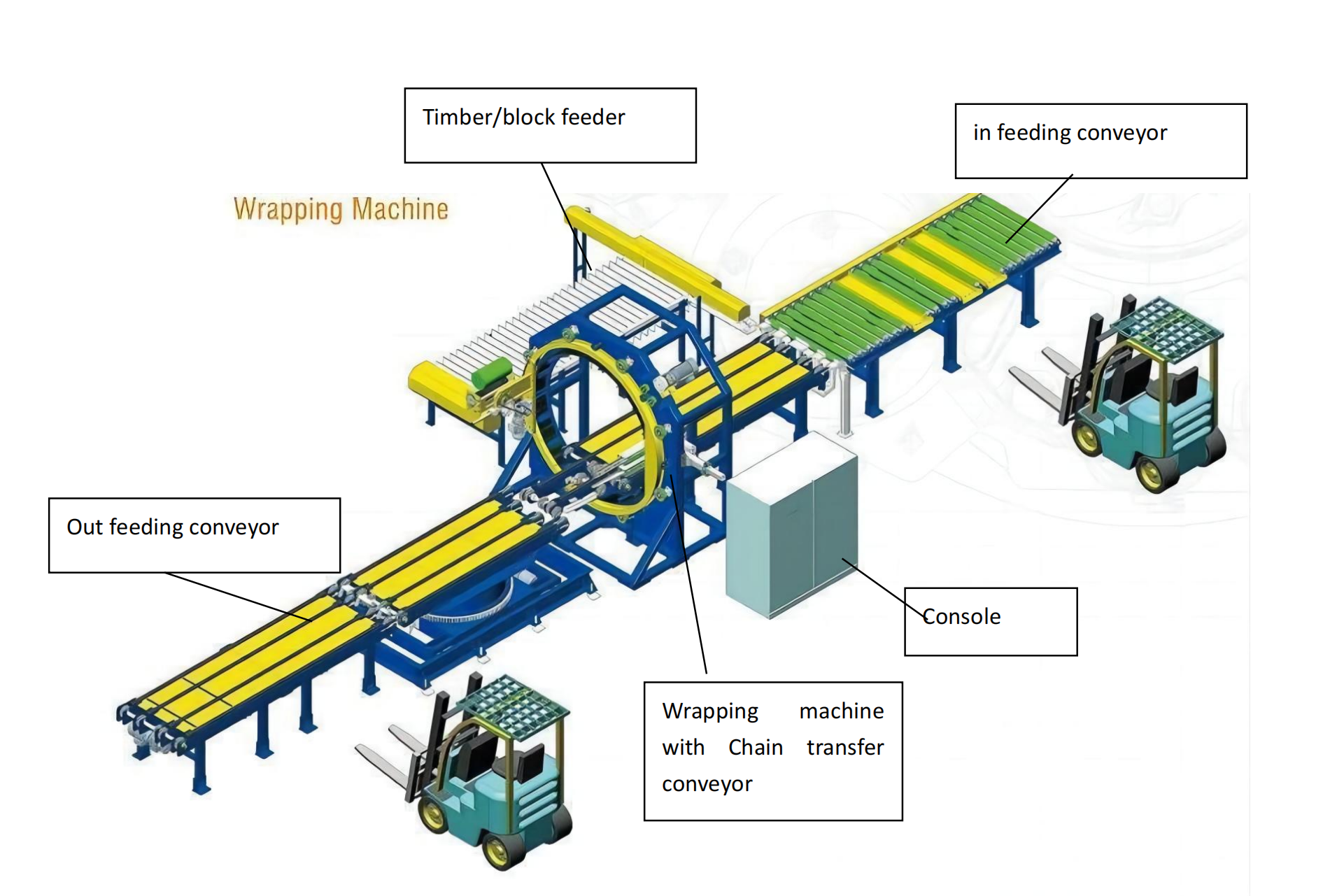

Automated Horizontal Stretch Wrapper

Investing in an automated horizontal stretch wrapper is essential for high-volume production environments where speed and consistency are critical. Here are the key factors to evaluate:

- Automation: Fully automated feeding, wrapping, and discharge for efficiency.

- Speed: Match wrapping speed to production needs to avoid delays.

- Versatility: Handle diverse product sizes and shapes.

- Consistency: Advanced controls ensure uniform wrapping and prevent damage.

- Film Efficiency: Optimize stretch film usage to cut waste and costs.

- Integration: Seamlessly connect with existing production lines.

- Durability: Robust build with easy maintenance for reliability.

By focusing on these key considerations, you can choose an automated horizontal stretch wrapper that boosts productivity while delivering consistent, high-quality packaging.

Customized Horizontal Stretch Wrapper

For businesses with unique packaging requirements, selecting a customized horizontal stretch wrapper is essential to meet specific production goals and product specifications. Key factors to consider include:

- Custom Fit: Ensure the machine matches your product size and wrapping needs.

- Special Handling: Choose options for unusual shapes or delicate items.

- Efficiency: Look for designs that minimize material waste and costs.

- Easy Integration: Verify compatibility with your existing systems.

- User-Friendly: Prioritize simple controls and easy maintenance.

- Built to Last: Select durable, high-quality machines for reliable performance.

Focus on these essentials for a more efficient and adaptable packaging solution.

Horizontal Stretch Wrapper

-

Semiauto Horizontal Stretch WrapperThe Semiauto Horizontal Stretch Wrapper is a versatile machine ideal for bundling elongated or uniquely shaped products. With its semi-automatic operation, it delivers consistent wrapping quality while minimizing labor. Perfect for industries requiring durable packaging, it enhances efficiency, reduces costs, and ensures products...

-

Automated Horizontal Stretch WrapperThe automated horizontal stretch wrapper offers efficient packaging for elongated or uniquely shaped items, ensuring stability and protection during transit. Its advanced automation minimizes manual effort, enhances wrapping precision, and optimizes productivity. Perfect for industries requiring reliable, high-volume packaging so...

-

Horizontal Stretch Wrappers For SaleHorizontal stretch wrappers are versatile machines designed to wrap stretch film around elongated or uniquely shaped products. Perfect for industries like steel, wood, or tubing, they ensure secure packaging, reduce waste, and enhance productivity. These machines are available in different configurations to meet specific business...

-

Horizontal Stretch Wrapper ManufacturerThe horizontal stretch wrapper is a reliable solution for wrapping elongated products with stretch film, ensuring secure packaging and protection during transportation. Widely used in industries like metal, wood, and textiles, it enhances efficiency, minimizes film usage, and delivers consistent results, making it an essential to...

-

Horizontal Stretch Wrapper PriceThe horizontal stretch wrapper offers a practical solution for securing products with stretch film, enhancing load stability and protection. Its pricing depends on specifications such as wrapping speed, material compatibility, and customization options. Designed for various industries, it ensures efficient packaging while reducin...