How to Choose a Horizontal Stretch Wrapping Machine That Matches Your Specific Packaging Needs

When it comes to industrial packaging, the horizontal stretch wrapping machine stands out as an essential tool for securing products efficiently. Whether you are dealing with timber, metal profiles, or fragile products, choosing the right horizontal stretch wrapper is vital for optimizing both your operations and your budget. However, with so many options available, how do you choose a machine that matches your specific packaging needs? This guide will take you through the key considerations and help you make an informed decision.

1. Understanding the Basics of Horizontal Stretch Wrapping Machines

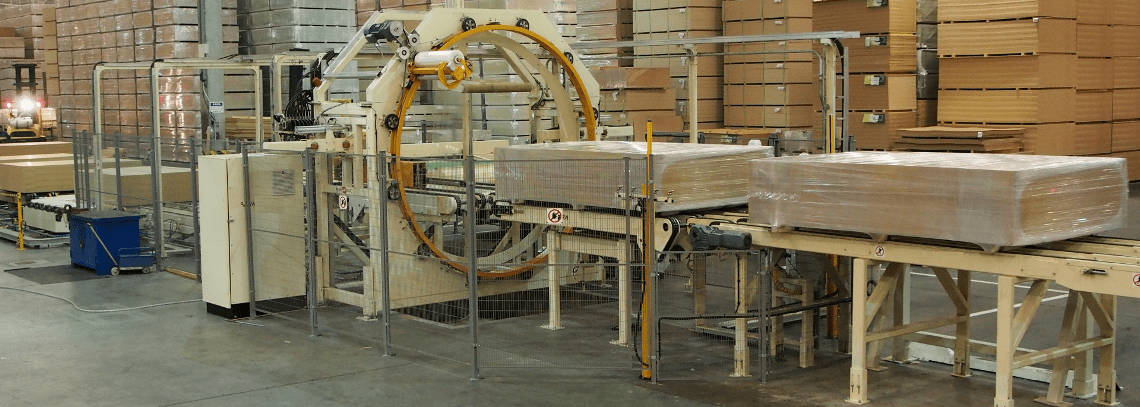

Before diving into specific features and factors, it’s essential to understand what a horizontal stretch wrapping machine does. These machines are designed to wrap items horizontally, applying stretch film around the product as it moves through the machine. This method is especially effective for long, narrow products such as pipes, profiles, or lumber, offering full protection while keeping the products secure during transit or storage.

2. The Importance of Matching Machine Specifications to Your Packaging Requirements

One of the first things you should consider is the size and shape of your products. Horizontal stretch wrappers come in various models, each designed for different product sizes. It's crucial to ensure that the machine you choose can handle the dimensions and weight of your products. For instance, larger products may require a machine with a wider wrapping ring, while smaller or lighter items might not need such robust equipment.

Consider the product length as well. If your packaging involves items that are particularly long, such as metal profiles or wooden planks, make sure the machine has the capacity to wrap these efficiently without sacrificing speed or precision.

3. Speed and Efficiency: Key Metrics for High-Volume Operations

Packaging speed is a significant factor, especially in industries where high-volume output is critical. You need to assess how fast the machine can wrap products and whether it aligns with your production schedule. High-speed wrapping machines can greatly enhance throughput, reducing downtime and labor costs.

Another crucial metric is the turntable speed or the rotation speed of the ring that wraps the film around the product. Faster turntable speeds allow for quicker wrapping cycles, which is essential for keeping up with high production demands. However, speed should not come at the cost of wrap quality or product security, so finding a balance is key.

4. Customization Options for Tailored Solutions

One of the significant benefits of modern horizontal stretch wrapping machines is the ability to customize them according to your unique needs. Many manufacturers offer features that can be tailored to your specific operations, such as adjustable film tension control, which ensures that the right amount of tension is applied for various product types, reducing the risk of damage.

Other customization options might include automated film cutting, programmable wrapping patterns, or enhanced conveyor systems for easier product handling. By choosing a machine that offers these options, you can optimize your packaging process and reduce human intervention, resulting in more consistent packaging and fewer errors.

5. Evaluating the Type of Film Used

Not all films are created equal, and the type of film your machine uses can significantly impact your packaging's effectiveness. Horizontal stretch wrapping machines typically use polyethylene (PE) stretch film, but you should evaluate whether the machine can handle different film types depending on your specific needs.

For instance, if you're dealing with fragile or delicate items, you may require a softer film that reduces the risk of damage during wrapping. Alternatively, for heavy or abrasive products, a more durable film that offers enhanced protection might be necessary. Some machines also have multi-film capabilities, allowing you to switch between films depending on the product.

6. Durability and Build Quality: Choosing a Long-Term Investment

When selecting a stretch wrapping machine, durability is one of the most critical factors. You want to ensure that the machine you invest in is built to last, particularly if you’re operating in demanding environments like construction or metal fabrication.

Look for machines made from high-quality materials such as stainless steel, which offers resistance to corrosion and can withstand harsh conditions. Additionally, machines with a solid build and robust components will have a longer lifespan, minimizing maintenance costs and downtime over the years.

7. Safety Features: Protecting Your Workforce and Products

In any industrial setting, safety is paramount. Horizontal stretch wrapping machines should come equipped with comprehensive safety features to protect both operators and products. Look for machines that offer automatic shutdown capabilities in the event of a malfunction or a safety hazard. Other features, such as emergency stop buttons and guarding systems, are essential for preventing workplace injuries.

You should also consider the machine’s user interface. Machines with intuitive controls reduce the risk of operator error and ensure that the machine can be used safely and effectively. Training your staff on the safety features of the machine is also a crucial step in preventing accidents.

8. Space Considerations and Layout

The footprint of your stretch wrapping machine is another vital consideration. Horizontal stretch wrapping machines can vary significantly in size, and you need to ensure that the machine fits comfortably within your existing production space. A machine that’s too large can disrupt workflows and lead to inefficiencies, while a machine that’s too small may not meet your production needs.

Additionally, think about the layout of your production line. Ideally, the wrapping machine should integrate seamlessly with your existing conveyor system, reducing the need for manual handling. Machines that allow for easy integration with automated systems are an excellent choice for businesses looking to enhance efficiency through automation.

9. Automation Levels: Manual vs. Fully Automatic Machines

One of the most critical decisions you'll make when choosing a horizontal stretch wrapping machine is deciding between a manual, semi-automatic, or fully automatic model. The level of automation you choose will depend on your production volume and labor availability.

-

Manual machines require significant human intervention, making them suitable for small businesses with lower packaging volumes.

-

Semi-automatic machines provide a balance between manual and automated operations, often requiring an operator to start the wrapping process but automating key steps like film application.

-

Fully automatic machines are ideal for high-volume operations, as they can handle the entire wrapping process without human intervention, significantly reducing labor costs and increasing output.

10. Conclusion: Finding the Perfect Match for Your Packaging Needs

Choosing the right horizontal stretch wrapping machine for your packaging needs is a decision that can have a long-lasting impact on your production efficiency, cost savings, and product security. By taking the time to evaluate key factors such as machine specifications, speed, customization options, film compatibility, durability, safety features, and automation levels, you can ensure that your investment meets both your current and future packaging requirements.

Whether you're looking for a machine to handle high volumes of timber or delicate metal profiles, the right horizontal stretch wrapper will improve your packaging process, increase efficiency, and protect your products during transit and storage.