Internal Decision Guide for Choosing Horizontal-Shrink-Wrap-Machine

Introduction: The Importance of Choosing the Right Horizontal-Shrink-Wrap-Machine

In today’s competitive business landscape, efficiency and product protection are paramount. Companies that deal with packaging, shipping, and product storage require robust and reliable packaging solutions to ensure their goods remain safe and secure throughout the logistics chain. One such packaging solution that has gained prominence is the Horizontal-Shrink-Wrap-Machine.

Choosing the right horizontal shrink wrap machine is crucial for optimizing product protection, improving packaging consistency, and maintaining operational efficiency. The decision-making process involves a careful evaluation of various factors, including machine capabilities, product requirements, budget constraints, and long-term cost considerations. A well-chosen shrink wrap machine can significantly improve workflow while reducing waste and minimizing operational costs.

This internal decision guide is designed to help businesses navigate the complexities of selecting a horizontal shrink wrap machine, providing a comprehensive analysis of key factors to consider for an informed investment. Whether you are upgrading your current packaging line or implementing a new system, this guide offers valuable insights to help you make the best decision.

Understanding Horizontal-Shrink-Wrap-Machines

What is a Horizontal-Shrink-Wrap-Machine?

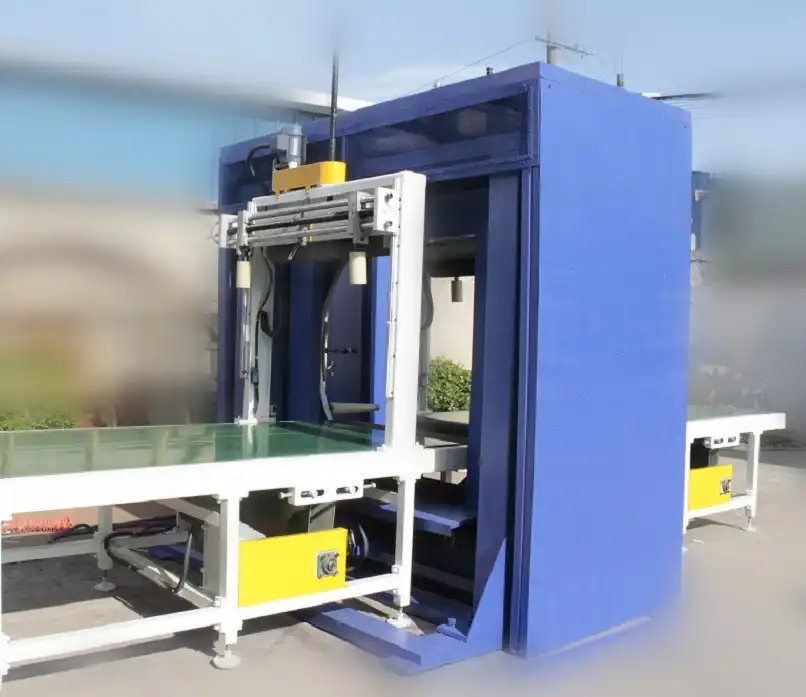

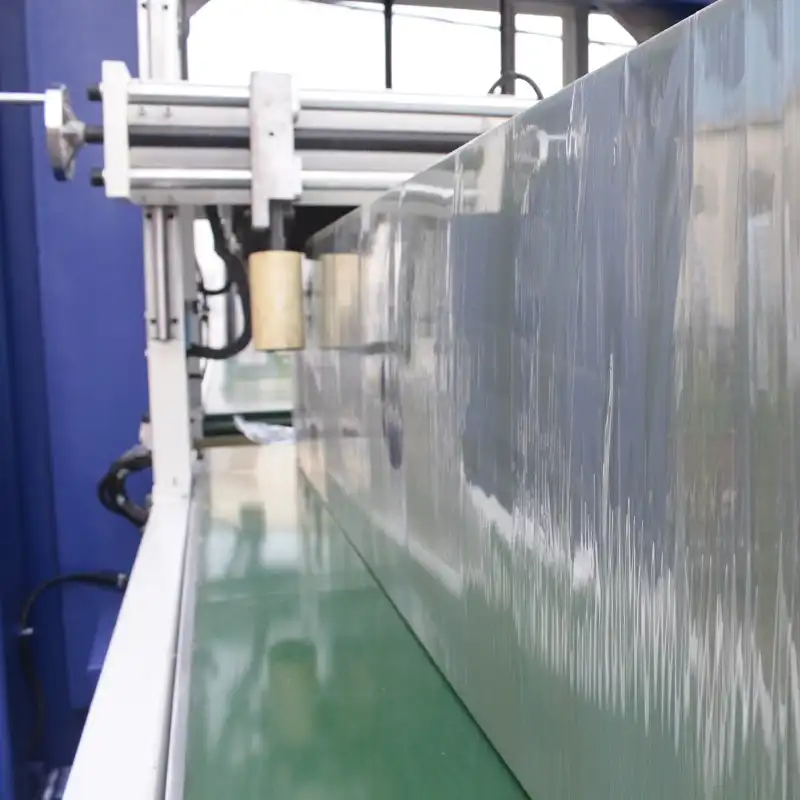

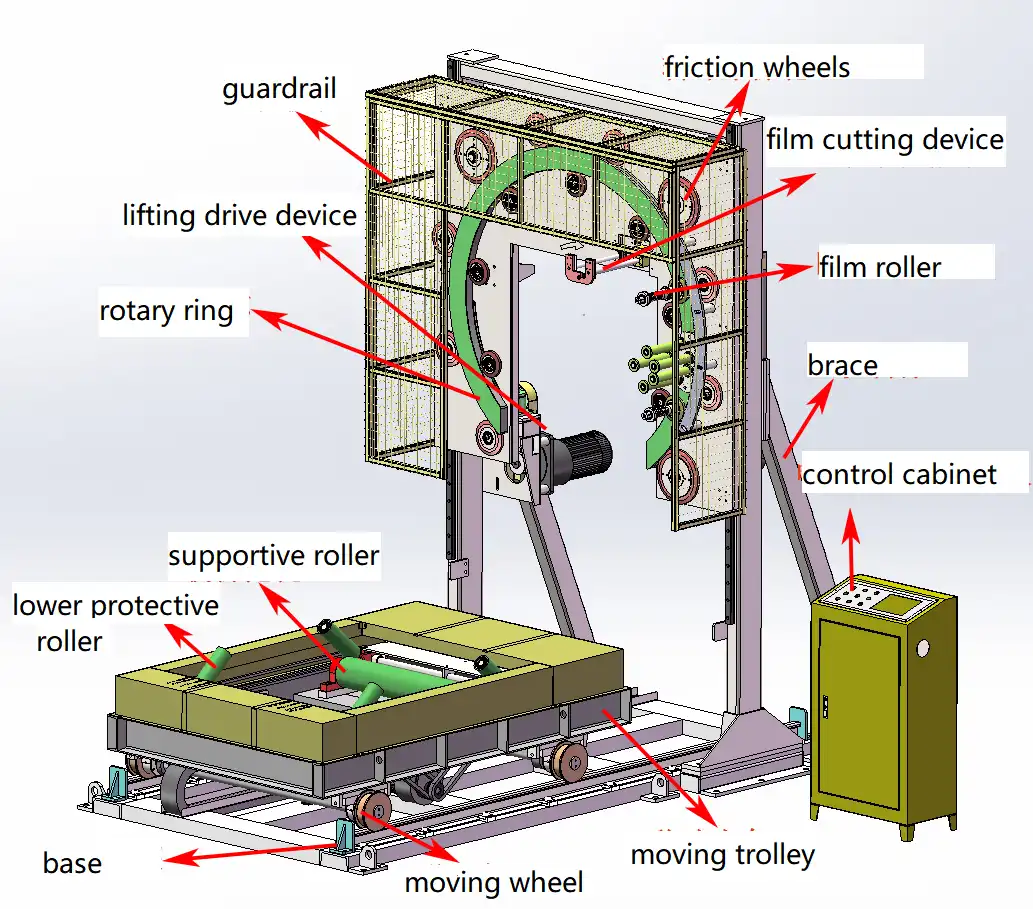

A Horizontal-Shrink-Wrap-Machine is a type of packaging machine designed to wrap products using shrink film. The machine places the product horizontally into a sleeve of film and then applies heat to shrink the film tightly around the product. This method provides a secure, tamper-evident, and visually appealing wrap that ensures the product is protected from dust, moisture, and other environmental factors during transport and storage.

Horizontal shrink wrap machines are especially beneficial for wrapping long, irregularly shaped, or bulky items such as furniture, doors, lumber, and other products that cannot be easily packaged with vertical wrapping machines. By securing the product in shrink film, these machines provide added structural support, protecting items from damage during handling and shipment.

Key Features of Horizontal-Shrink-Wrap-Machines

When evaluating horizontal shrink wrap machines, several key features are essential to consider:

-

Automated operation: These machines typically offer full or semi-automatic operation, reducing the need for manual intervention and increasing packaging speed.

-

Adjustable settings: Many machines allow users to adjust film tension, wrapping speed, and heat application to accommodate different product sizes and packaging requirements.

-

Versatile film compatibility: Horizontal shrink wrap machines are compatible with various types of shrink films, such as polyethylene, polyolefin, and PVC, allowing businesses to choose the material that best suits their product.

-

Safety features: Modern machines are equipped with safety mechanisms, such as emergency stop buttons and heat-resistant components, ensuring safe operation in fast-paced environments.

These features contribute to improved packaging consistency, operational efficiency, and enhanced product protection, making horizontal shrink wrap machines a valuable investment for businesses in various industries.

Key Considerations for Selecting the Right Horizontal-Shrink-Wrap-Machine

Product Type and Size

One of the most critical factors to consider when choosing a horizontal shrink wrap machine is the type and size of the products that need to be wrapped. Not all machines are built to handle the same dimensions or weights, and selecting a machine that aligns with your product specifications is essential to ensure optimal packaging performance.

For example, if your business deals with packaging long or bulky items such as doors, pipes, or construction materials, you will need a machine capable of handling such dimensions. Machines with adjustable wrapping and conveyor settings are ideal for businesses with a wide range of product sizes, as they offer greater flexibility in packaging different items.

In addition, the weight of the product is also a crucial consideration. Ensure that the machine’s conveyor and film application system can support the weight of your product without causing operational strain or mechanical failure.

Speed and Throughput

The speed and throughput of the machine are equally important when evaluating different options. Speed refers to how quickly the machine can wrap individual products, while throughput refers to the total number of products the machine can handle within a specific timeframe.

For businesses with high production volumes, choosing a machine with fast wrapping speeds and high throughput capabilities is essential to maintain productivity. Some horizontal shrink wrap machines can wrap several items per minute, significantly improving operational efficiency and reducing bottlenecks in the packaging line.

Conversely, smaller businesses or those with lower production volumes may not require machines with extremely high speeds. In such cases, investing in a machine that matches your production needs, rather than paying for unnecessary speed, can save costs without compromising on quality.

Film Type and Material Costs

The type of shrink film you plan to use plays a significant role in determining the cost-effectiveness of your horizontal shrink wrap machine. Different films have varying costs, durability, and protective properties, and selecting the right one can influence your overall packaging expenses.

-

Polyethylene (PE): Often used for heavy-duty packaging, this film is strong, durable, and suitable for large or heavy products.

-

Polyolefin (POF): A popular choice for food and consumer goods packaging, polyolefin is flexible, durable, and produces clear, professional-looking packaging.

-

Polyvinyl Chloride (PVC): Known for its high clarity and shrink ratio, PVC is ideal for retail packaging but can be less durable than other materials.

Consider the cost and availability of film materials when selecting your machine. Machines that are compatible with multiple film types offer greater flexibility and allow you to switch between materials based on product requirements or budget constraints.

Evaluating the Supplier and Machine Manufacturer

Reputation and Track Record

The reputation of the supplier or manufacturer you choose can significantly impact the long-term performance and reliability of your shrink wrap machine. Established suppliers with a proven track record in the industry are more likely to provide high-quality machines and offer better customer support than lesser-known suppliers.

Look for suppliers that have positive reviews, a history of successful installations, and clients within your industry. Suppliers that offer ongoing support and maintenance services can help ensure that your machine continues to operate at peak performance, reducing the risk of downtime and unexpected breakdowns.

After-Sales Support and Maintenance

Another critical aspect to consider is the level of after-sales support offered by the supplier. Shrink wrap machines require regular maintenance and, occasionally, repairs to keep them running smoothly. Choosing a supplier that offers comprehensive after-sales support, including spare parts availability, technical assistance, and routine maintenance services, can prevent costly downtime and extend the lifespan of your machine.

It’s essential to verify whether the supplier provides on-site support and how quickly they can respond to maintenance requests. Prompt service can make a significant difference in minimizing production delays and maintaining consistent output.

Cost Considerations: Balancing Budget and Value

Initial Investment vs. Long-Term Costs

The initial cost of purchasing a horizontal shrink wrap machine is often the primary focus for businesses. However, it’s crucial to also consider the long-term costs associated with operating and maintaining the machine. While cheaper machines may offer short-term savings, they could result in higher long-term expenses due to increased maintenance, downtime, and lower efficiency.

More advanced machines with automation features and higher build quality may come with a higher price tag, but they typically deliver better value over time. These machines require less manual intervention, use film more efficiently, and are generally more reliable, reducing the overall cost of ownership.

Energy Efficiency and Operating Costs

Energy consumption is another important cost factor. Some horizontal shrink wrap machines are designed with energy-efficient features that help reduce electricity consumption, particularly during extended operations. Choosing an energy-efficient machine can lead to significant savings in the long run, especially for businesses with high-volume packaging requirements.

Additionally, consider the machine’s impact on your operating costs, including the cost of film, labor, and maintenance. By balancing the initial investment with these long-term considerations, businesses can make a more cost-effective decision.

Comparing Horizontal-Shrink-Wrap-Machine Options

Fully Automated vs. Semi-Automated Machines

When selecting a horizontal shrink wrap machine, one of the key decisions businesses must make is whether to choose a fully automated or semi-automated system.

-

Fully automated machines offer the highest level of efficiency and require minimal human intervention. These machines are ideal for businesses with high production volumes and consistent packaging requirements. Fully automated systems typically provide faster wrapping speeds and increased throughput.

-

Semi-automated machines require some manual operation, such as loading products or initiating the wrapping process. While they may be slower than fully automated systems, semi-automated machines are often more affordable and suitable for businesses with lower production volumes or variable packaging needs.

Industry-Specific Solutions

Different industries have unique packaging requirements, and selecting a machine that aligns with these needs is essential. For example, the food and beverage industry may prioritize machines that offer sanitary packaging options and use FDA-approved shrink films, while automotive or construction industries may require machines that handle larger, heavier products.

Evaluating the specific features and capabilities of each machine, and how they fit into your industry’s packaging standards, can help businesses make an informed choice that maximizes operational efficiency.

Conclusion: Making an Informed Decision for Cost-Effective Packaging

Selecting the right Horizontal-Shrink-Wrap-Machine is a critical decision that can have a lasting impact on your company’s operational efficiency, product safety, and overall packaging costs. By carefully considering factors such as product size, machine speed, film type, supplier reputation, and long-term costs, businesses can ensure they choose a machine that aligns with their needs.

Whether opting for a fully automated system for high-volume operations or a semi-automated