Supplier Selection Guide: Ring Orbital Wrapping Machine for Cost Optimization

Introduction: The Importance of Supplier Selection in Ring Orbital Wrapping Machines

In the fast-paced world of manufacturing and logistics, choosing the right ring orbital wrapping machine is critical for improving operational efficiency and reducing costs. These machines, which provide high-speed and secure wrapping for cylindrical products such as pipes, tubes, or rolls, are essential for businesses looking to streamline their packaging processes. However, the efficiency and long-term performance of a wrapping machine depend not only on its design and features but also on the supplier you choose.

Selecting the right supplier for your ring orbital wrapping machine is a strategic decision that can directly impact your company's cost optimization. A reliable supplier offers more than just the equipment—they provide ongoing support, customization options, and valuable insights that help businesses maximize the return on their investment. In contrast, choosing the wrong supplier can lead to higher maintenance costs, operational inefficiencies, and frequent breakdowns, ultimately harming your bottom line.

This guide provides a comprehensive overview of what businesses should look for when selecting a supplier for ring orbital wrapping machines, emphasizing cost-saving opportunities, supplier reliability, and key considerations that will help you make the best choice.

Understanding Ring Orbital Wrapping Machines

What Are Ring Orbital Wrapping Machines?

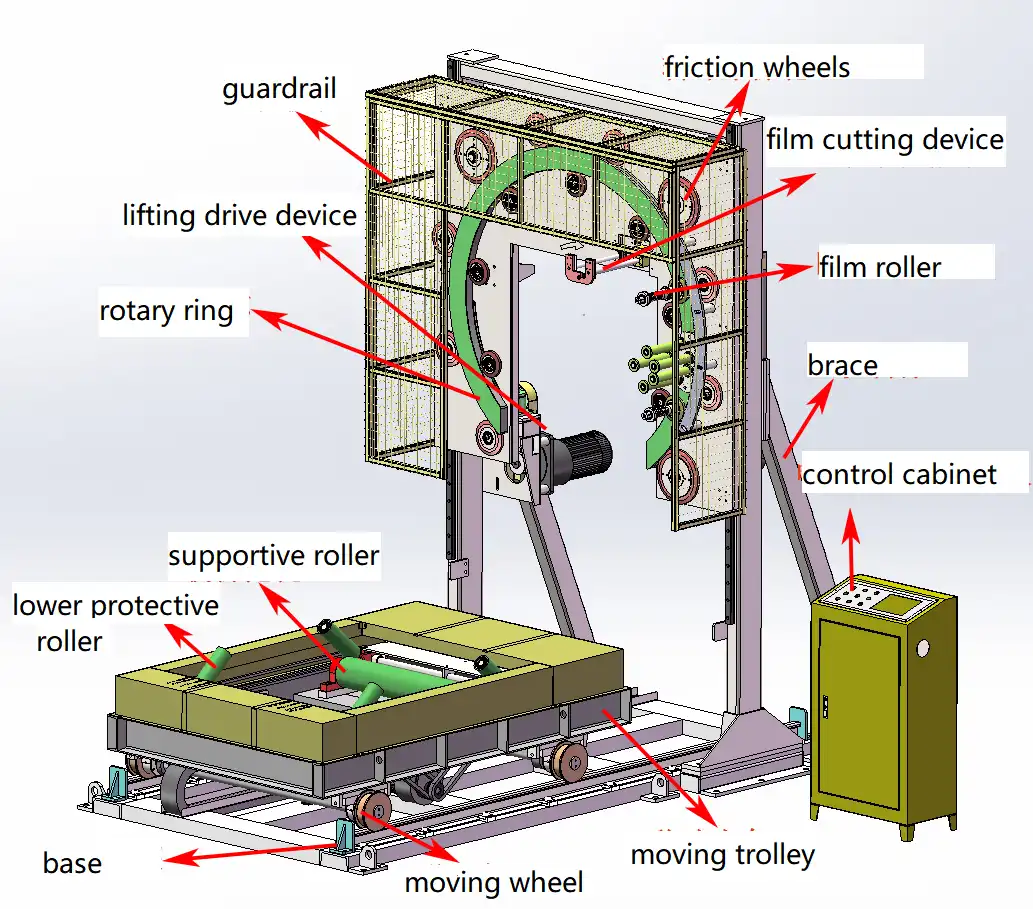

Ring orbital wrapping machines are specialized packaging machines designed to wrap cylindrical products using a ring-shaped wrapping mechanism. Unlike standard wrapping machines that operate horizontally, these machines allow for the 360-degree wrapping of products with minimal human intervention. The wrapping is done using stretch film or other protective materials, which are tightly applied around the product to secure it for transport or storage.

These machines are particularly popular in industries such as steel, aluminum, plastic pipe manufacturing, and other sectors where long, cylindrical products require consistent and reliable packaging. The automated nature of ring orbital wrapping machines means that businesses can increase their packaging speed, reduce labor costs, and ensure that products are protected from damage, moisture, and dust.

Key Features of Ring Orbital Wrapping Machines

Ring orbital wrapping machines come with several key features that make them suitable for cost optimization in industrial settings:

-

Automated wrapping: Reduces the need for manual labor, increasing speed and efficiency.

-

Customizable settings: Allows businesses to adjust wrapping tension, speed, and film usage to suit different product requirements.

-

Durable construction: Designed to handle high-volume operations and withstand heavy-duty use.

-

Precision control systems: Ensures consistent wrapping and minimizes film waste, reducing material costs.

These features make ring orbital wrapping machines an essential tool for businesses that want to optimize their packaging operations and reduce costs over time.

Why Supplier Selection Matters for Cost Optimization

The Role of the Supplier in Long-Term Cost Savings

When purchasing a ring orbital wrapping machine, businesses often focus on the upfront cost of the machine itself. While the purchase price is an important factor, the true cost of ownership extends far beyond the initial investment. The supplier you choose plays a critical role in determining your long-term costs, from maintenance and repair expenses to the availability of parts and after-sales support.

A reliable supplier offers more than just the machine—they provide ongoing support that ensures your equipment operates at peak efficiency throughout its lifespan. This support includes timely maintenance, access to spare parts, and technical guidance that can help you prevent costly breakdowns or delays in your packaging operations.

On the other hand, choosing a supplier that does not offer reliable support can lead to increased downtime, frequent repairs, and higher operational costs. Additionally, suppliers who do not provide quality parts or have poor customer service can hinder your ability to optimize costs and maintain smooth operations.

Impact of Machine Quality on Operational Costs

The quality of the machine provided by the supplier also significantly impacts operational costs. High-quality ring orbital wrapping machines are more durable, require less frequent maintenance, and consume fewer wrapping materials. This translates into lower long-term expenses for businesses. In contrast, lower-quality machines may have a higher likelihood of mechanical failure, leading to increased maintenance costs, replacement parts, and operational disruptions.

For businesses focused on cost optimization, it is crucial to select a supplier that delivers high-performance machines with a proven track record of durability and efficiency.

Key Factors to Consider When Choosing a Supplier

1. Supplier Reputation and Track Record

The reputation of the supplier is one of the most important factors to consider when selecting a ring orbital wrapping machine provider. A supplier with a solid track record in the industry is more likely to provide high-quality machines and reliable after-sales support. Look for suppliers with positive reviews, customer testimonials, and case studies that demonstrate their ability to deliver successful solutions to other businesses in your industry.

Additionally, reputable suppliers are often more transparent about the quality and performance of their machines. They will be willing to provide detailed information about the machine’s features, technical specifications, and performance history, allowing you to make an informed decision.

2. Customization and Flexibility

No two businesses have the same packaging requirements. The best suppliers offer customizable machines that can be tailored to meet your specific needs. Whether you need to adjust the size of the wrapping ring, the type of wrapping material used, or the speed of the machine, a supplier that offers flexible solutions will help you optimize costs by ensuring that the machine is perfectly suited to your operation.

Customization also extends to after-sales service. A good supplier will work with you to develop a maintenance plan that fits your usage patterns, ensuring that your machine receives regular servicing to prevent costly breakdowns.

3. Technical Support and After-Sales Service

Even the best machines require regular maintenance and occasional repairs. When choosing a supplier, it’s essential to consider their level of technical support and the availability of after-sales service. A reliable supplier will provide ongoing support, including:

-

24/7 technical assistance to resolve any operational issues.

-

Spare parts availability to minimize downtime in case of mechanical failure.

-

On-site service for complex repairs and maintenance.

Suppliers that offer strong after-sales support ensure that your machine remains operational, which is crucial for maintaining high levels of productivity and cost efficiency.

4. Cost Transparency and Total Cost of Ownership (TCO)

The upfront cost of a ring orbital wrapping machine is only part of the equation. The total cost of ownership (TCO) includes not only the purchase price but also the costs associated with maintenance, repairs, energy consumption, and film usage over the machine’s lifespan. A reputable supplier will provide a clear breakdown of these costs, allowing you to calculate the long-term financial impact of the machine.

When evaluating suppliers, be sure to ask for detailed information about the machine’s expected energy consumption, maintenance requirements, and film efficiency. Suppliers that offer machines with energy-saving features or reduced film waste can help you lower operating costs and improve your return on investment.

Comparing Suppliers for Optimal Cost Efficiency

Supplier A: Industry-Leading Technology with Comprehensive Support

Supplier A is known for its advanced technology and high-performance ring orbital wrapping machines. They offer fully automated systems that integrate with existing production lines, helping businesses achieve maximum efficiency. Their machines feature precision control systems that minimize film waste, making them an excellent choice for companies focused on cost optimization.

Supplier A also offers 24/7 customer support, with a dedicated team of technicians available for on-site repairs and maintenance. Their comprehensive after-sales service ensures that your machine continues to operate at peak efficiency, reducing downtime and minimizing unexpected costs.

Supplier B: Affordable Solutions with Limited Customization

Supplier B offers more affordable options for businesses looking to save on initial costs. Their machines are reliable and durable but offer fewer customization options compared to Supplier A. While their machines are suitable for businesses with basic packaging needs, they may not be ideal for companies that require highly specialized or customizable solutions.

Supplier B’s after-sales support is also more limited, with fewer options for technical assistance and spare parts availability. This could result in higher long-term costs if repairs are needed frequently or if downtime becomes an issue.

Supplier C: Mid-Range Machines with Focus on Sustainability

Supplier C offers mid-range machines that balance cost and performance. They focus on sustainability, providing machines that consume less energy and use environmentally friendly wrapping materials. This makes them an excellent choice for businesses looking to reduce their environmental impact while also optimizing costs.

Supplier C’s machines are customizable, allowing businesses to tailor the wrapping process to their specific needs. They also offer remote monitoring capabilities, enabling operators to track machine performance and identify potential issues before they lead to costly breakdowns.

Conclusion: Making the Right Supplier Choice for Cost Optimization

Choosing the right supplier for your ring orbital wrapping machine is a crucial step toward optimizing costs and improving the efficiency of your packaging operations. A reliable supplier not only provides high-quality machines but also delivers ongoing support, customization options, and transparent cost information that helps businesses make informed decisions.

When selecting a supplier, consider their reputation, ability to provide customized solutions, level of after-sales service, and transparency regarding total cost of ownership. By making the right choice, your business can significantly reduce operational costs, improve productivity, and ensure long-term success in today’s competitive market.