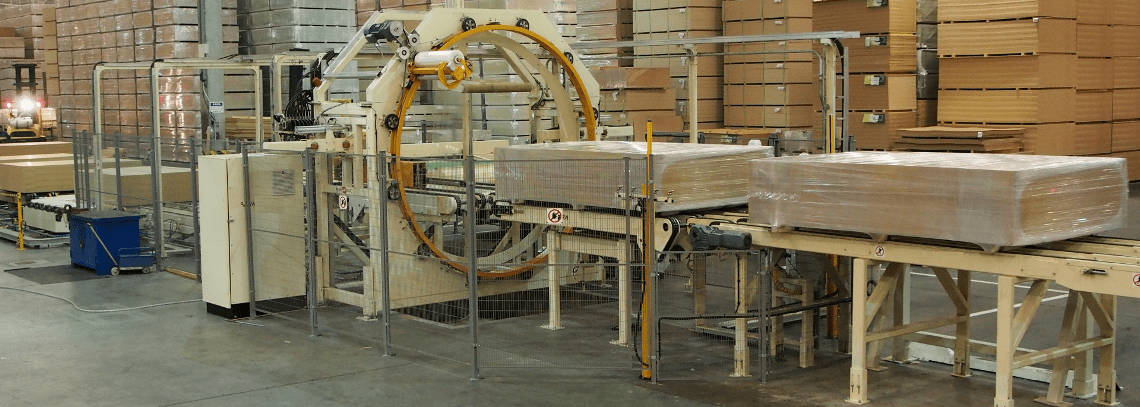

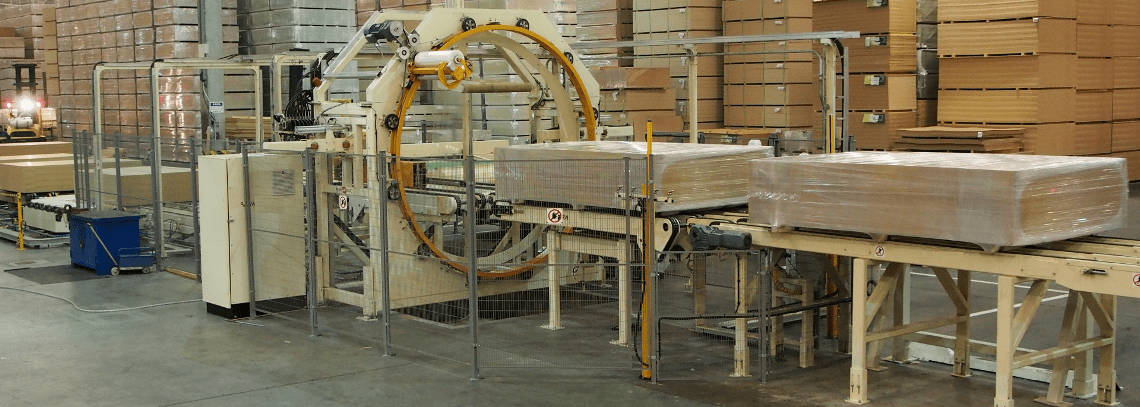

Semiauto Horizontal Stretch Wrapper

In the world of industrial packaging, efficiency and precision are not just desirable—they are essential. As businesses scale and supply chains grow more complex, the need for reliable, adaptable, and cost-effective packaging solutions becomes undeniable. Among the options available, the semiauto horizontal stretch wrapper emerges as a pivotal tool for operations requiring secure and streamlined product handling.

The semiauto horizontal stretch wrapper is not just another packaging machine; it is a game-changer for industries managing products of varying shapes and sizes. Whether you're wrapping pipes, panels, or elongated goods, this machine combines manual oversight with automated precision to achieve optimal outcomes. Its versatile design and adaptability make it indispensable in industries where speed and consistency are paramount.

This article delves deep into the workings, benefits, and considerations of choosing the right semiauto horizontal stretch wrapper for your business. If you’re aiming to enhance your packaging line while maintaining a balance between investment and operational efficiency, read on for actionable insights and expert analysis.

1. How Does a Semiauto Horizontal Stretch Wrapper Enhance Your Packaging Process?

1.1 Understanding the Functionality

At its core, a semiauto horizontal stretch wrapper is designed to secure elongated products by wrapping them with stretch film, ensuring stability during transportation and storage. Unlike fully automatic systems, this machine offers a blend of manual control and automated wrapping precision, making it suitable for businesses transitioning to more efficient operations without sacrificing oversight.

1.2 Advantages for Diverse Applications

One of the standout features of this equipment is its ability to handle a wide range of products. From delicate materials like wooden planks to robust steel pipes, the semiauto horizontal stretch wrapper adapts seamlessly. This versatility ensures businesses can achieve consistent packaging standards regardless of product type, boosting both customer satisfaction and operational efficiency.

1.3 Why Efficiency Matters

The efficiency of the semiauto horizontal stretch wrapper is not just about speed but also about reducing waste and minimizing errors. By ensuring even tension and coverage, the machine reduces the chances of product damage and film wastage. In turn, this leads to cost savings and a more sustainable packaging process, aligning with the modern industry's push for eco-friendly practices.

2. What Features Should You Prioritize in a Semiauto Horizontal Stretch Wrapper?

2.1 Assessing Durability and Build Quality

When investing in a semiauto horizontal stretch wrapper, durability should be at the forefront of your considerations. Machines constructed with robust materials and precision engineering promise longevity and reduced maintenance needs, ensuring your investment remains cost-effective over time.

2.2 Key Operational Features

Look for adjustable speed controls, film tension settings, and a user-friendly interface. These features not only enhance the machine's adaptability to various products but also ensure that your team can operate it efficiently with minimal training. A thoughtful design can significantly reduce downtime, which is critical in high-volume operations.

2.3 Exploring Advanced Customization

Customization options like tailored wrapping programs, compatibility with specific film types, and modular add-ons make a world of difference. These features allow the semiauto horizontal stretch wrapper to grow with your business needs, providing flexibility and scalability as your operation

3. How to Optimize Your Workflow with a Semiauto Horizontal Stretch Wrapper?

3.1 Identifying Bottlenecks in Your Current Process

Workflow optimization starts with identifying inefficiencies. In many cases, manual wrapping processes lead to delays and inconsistent packaging quality. A semiauto horizontal stretch wrapper helps address these issues by streamlining operations and providing a consistent, reliable solution for packaging elongated products.

3.2 Integrating the Wrapper into Existing Operations

Seamlessly integrating the wrapper into your current setup is crucial. With adjustable settings and a straightforward interface, this machine can align with your production line’s existing workflow without causing significant disruptions. Training your team on its functionality further ensures a smooth transition, minimizing downtime.

3.3 The Importance of Regular Maintenance

To maintain peak performance, regular inspections and maintenance are necessary. Ensuring that moving parts are lubricated and components are in optimal condition can extend the machine’s lifespan. Additionally, addressing minor issues early prevents costly repairs down the line, safeguarding your investment.

4. What Are the Long-Term Benefits of Investing in This Equipment?

4.1 Enhanced Product Protection

The consistent wrapping provided by a semiauto horizontal stretch wrapper reduces the risk of damage during transportation and storage. Secure packaging ensures your products reach customers in pristine condition, enhancing your brand’s reputation and minimizing losses caused by returns or damaged goods.

4.2 Reduced Operational Costs

While the initial investment might seem substantial, the long-term savings outweigh the costs. By automating a significant portion of the wrapping process, you reduce labor expenses and material wastage. Over time, these savings contribute to a higher return on investment, making this equipment a cost-effective choice for growing businesses.

4.3 Supporting Sustainability Goals

Modern industries are increasingly focused on sustainability. Using a semiauto horizontal stretch wrapper aligns with eco-friendly practices by optimizing film usage and reducing waste. Additionally, its energy-efficient design ensures that your operations remain environmentally conscious, appealing to clients and partners prioritizing sustainability.

Conclusion

The semiauto horizontal stretch wrapper represents more than just a packaging solution—it is an essential investment for businesses aiming to stay competitive in fast-paced industries. By enhancing efficiency, reducing costs, and supporting sustainability efforts, this equipment provides a well-rounded solution to packaging challenges.

[Claim] Investing in a semiauto horizontal stretch wrapper not only elevates your packaging standards but also positions your business for long-term growth and success. Make the move today and experience the transformative benefits this innovative equipment brings to your operations.