Fhopepack Innovation

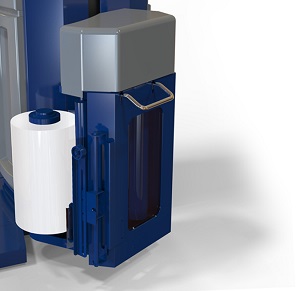

Pallet stretch wrapper with cutter,pallet stretch film wrapping machine

This is a pallet stretch wrapping machine with Siemens PLC, the program standard with 10 options. And even it is more packaging mode with highly configurable. Fhope Semiatuo stretch wrapper machines have a good reputation in factory, warehouse...for doing wrapping job to save the cost.