Is It Worth Paying More for Advanced Features in an Orbital Pallet Wrapper?

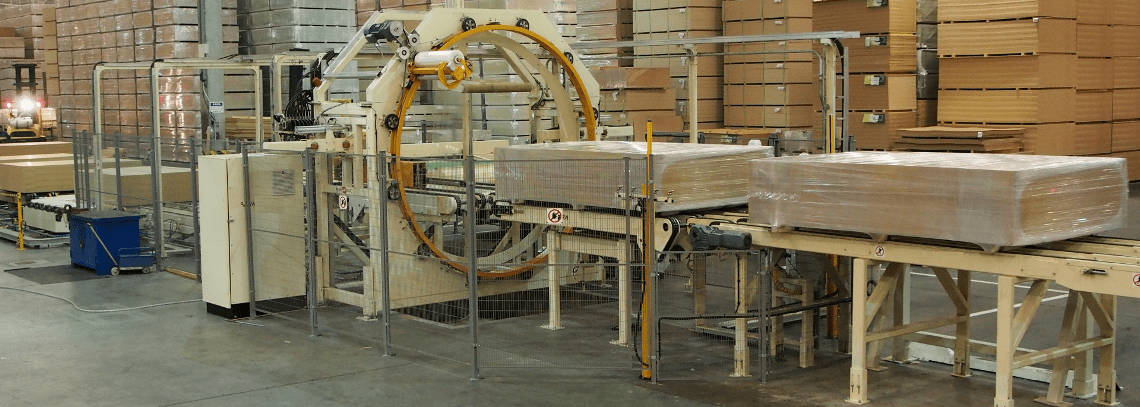

In the world of modern packaging solutions, orbital pallet wrappers are essential equipment, especially for businesses with high-volume packaging needs. These machines automate the process of wrapping products, offering efficiency, consistency, and cost savings. But when it comes to choosing an orbital pallet wrapper, many businesses find themselves debating whether it's worth paying more for advanced features. Should you opt for the basic model or invest in a high-end solution with all the bells and whistles? This article dives deep into the pros and cons of investing in advanced features in orbital pallet wrappers, helping you make a well-informed decision.

1. Understanding the Basic Features of an Orbital Pallet Wrapper

Before exploring advanced features, it's important to know what a standard orbital pallet wrapper typically offers. At its core, the machine wraps a stretch film around the palletized goods in a horizontal direction. This protects the products during transit and storage, preventing damage from dust, moisture, and mechanical forces.

Standard features generally include:

-

Manual or semi-automatic operation

-

Adjustable film tension

-

Simple control interface

-

Fixed wrapping speed

-

Basic safety sensors

These features are enough for businesses with moderate packaging needs, but as the demand for productivity increases, so does the need for more sophisticated solutions.

2. What Are the Advanced Features in Orbital Pallet Wrappers?

Advanced features go beyond the basics to add automation, efficiency, and safety to the wrapping process. Some common high-end features include:

-

Fully automatic operation: The machine can handle the entire wrapping process without operator intervention.

-

Customizable wrapping patterns: Some machines allow for different wrapping modes tailored to specific product types.

-

Automatic film cutting and sealing: This eliminates the need for manual cutting, speeding up the wrapping process.

-

Adjustable wrapping speeds: Enables faster wrapping for high-throughput environments.

-

Remote monitoring and diagnostics: Offers real-time monitoring of machine performance and maintenance needs.

-

Safety features: Advanced safety sensors, automatic shutdown during malfunctions, and built-in guarding systems.

-

Touchscreen interfaces: More user-friendly and offer greater control over the machine’s settings.

3. Evaluating the Cost-Benefit Ratio

The decision to pay more for advanced features should be weighed against the potential benefits they bring. Automation can drastically reduce labor costs, while faster wrapping speeds increase throughput. However, if your packaging volume is low, investing in advanced features may not provide an immediate return on investment.

Consider the long-term savings from reduced film wastage, lower labor costs, and fewer product damages. An automated machine will likely pay for itself over time if you’re running a high-volume operation.

4. Impact of Advanced Features on Operational Efficiency

The most compelling reason to invest in advanced features is the boost in operational efficiency. A fully automated orbital pallet wrapper can perform tasks faster and more consistently than manual or semi-automatic machines. For businesses looking to scale up or handle increased production demands, this is crucial.

Let’s take the example of a fully automatic film cutting and sealing system. By eliminating the need for manual intervention, operators can focus on other tasks, thereby increasing overall productivity. Additionally, customizable wrapping patterns allow businesses to optimize the amount of film used, which minimizes waste and reduces costs.

5. Enhancing Product Protection with Advanced Wrapping Modes

Another key benefit of advanced features is improved product protection. Customizable wrapping modes allow businesses to tailor the wrapping process to the type of goods being packaged. For instance, fragile or oddly shaped items can be wrapped more securely with specialized patterns, ensuring they arrive at their destination intact.

Investing in a machine that offers pre-stretch film capability can also improve product stability on the pallet while using less film. This feature ensures the film is stretched to its maximum efficiency, providing greater load containment and cost savings.

6. Reducing Downtime Through Predictive Maintenance

One of the often-overlooked advantages of higher-end machines is their ability to offer remote diagnostics and predictive maintenance. With real-time data on machine performance, businesses can identify potential issues before they cause breakdowns. This proactive approach to maintenance minimizes downtime, which is especially important in industries with tight production schedules.

A machine that’s down for repairs can lead to costly delays, missed deadlines, and frustrated customers. Advanced features like remote monitoring ensure that you stay ahead of potential problems, keeping your operations running smoothly.

7. Safety Considerations: Is It Worth the Investment?

When handling large pallets and industrial machinery, safety is paramount. High-end orbital pallet wrappers often come equipped with enhanced safety features that can reduce the risk of accidents and injuries in the workplace. These features include automatic shutdown mechanisms, emergency stop buttons, and advanced sensors that detect obstructions.

While these safety features come at an added cost, the potential savings in reduced workplace injuries and downtime due to accidents can be substantial. For companies that prioritize workplace safety and adhere to strict regulatory requirements, investing in advanced safety options is a wise decision.

8. Advanced Technology for Data Tracking and Process Optimization

In today’s increasingly digital world, data tracking and process optimization are becoming more important in manufacturing and logistics. Many advanced orbital pallet wrappers offer IoT integration and data analytics capabilities, allowing businesses to monitor and improve their packaging processes in real-time.

With IoT-enabled features, you can track metrics such as:

-

Film usage per pallet

-

Wrapping time per cycle

-

Machine uptime and downtime

-

Maintenance alerts

This data provides valuable insights that can help you fine-tune your operations, reduce waste, and maximize machine performance. Additionally, the ability to integrate this data into larger enterprise resource planning (ERP) systems can provide a holistic view of your packaging line's efficiency.

For businesses aiming to implement Industry 4.0 strategies, these advanced technological features can provide a significant competitive edge.

9. Tailoring Features to Specific Industry Needs

Different industries have unique packaging requirements, and advanced features in orbital pallet wrappers can be tailored to meet these specific needs. For example:

-

Food and beverage industry: Wrapping machinery in this sector may require features that meet hygiene standards, such as easy-to-clean surfaces and materials that prevent contamination.

-

Pharmaceuticals: Advanced features like precise tension control are essential to ensure delicate packages aren’t damaged during wrapping.

-

Automotive and heavy equipment: Robust machines with features like reinforced wrapping and enhanced load stability are necessary to handle the weight and size of parts.

By investing in advanced features, businesses in specialized industries can ensure that their packaging operations meet sector-specific requirements while improving speed, safety, and efficiency.

10. Future-Proofing Your Investment

When considering whether to invest in advanced features, it’s important to think about future-proofing. Packaging technology is evolving rapidly, and investing in a machine that can adapt to future needs is a smart choice. Machines with modular designs or the ability to upgrade software offer flexibility, allowing you to add new features as they become available.

If you anticipate your business growing or your packaging needs changing in the future, paying more upfront for an advanced machine could save you from needing to replace or retrofit equipment down the line. This forward-thinking approach helps businesses stay competitive and adapt to market changes without major disruptions to their operations.

11. Balancing Budget Constraints with Long-Term Gains

Budget considerations are always a major factor when making capital investments, and orbital pallet wrappers are no exception. High-end machines with advanced features tend to come with a steeper initial cost, which can be a deterrent for small to mid-sized businesses. However, it’s important to balance these costs against the long-term gains they provide.

For businesses with high packaging volumes, the cost savings from reduced labor, faster cycle times, and lower material usage can quickly offset the initial investment. Moreover, the increased machine lifespan and lower maintenance costs that come with premium models often make them more economical in the long run.

12. Real-World Examples of ROI from Advanced Features

Several companies have experienced significant ROI after upgrading to orbital pallet wrappers with advanced features. For example:

-

A large beverage distributor saw a 30% reduction in film usage after switching to a machine with pre-stretch capability.

-

An automotive parts manufacturer reduced labor costs by 50% thanks to a fully automated wrapping process that required no operator intervention.

-

A logistics company increased productivity by 20% after upgrading to a model with customizable wrapping patterns, allowing for more efficient packaging of varied product sizes.

These real-world examples highlight how advanced features can directly translate to improved operational performance and cost savings.

Conclusion: Are Advanced Features Worth the Extra Cost?

So, is it worth paying more for advanced features in an orbital pallet wrapper? The answer largely depends on the size of your operation, the complexity of your packaging needs, and your long-term goals. For businesses with high packaging volumes, advanced features like automation, customizable wrapping patterns, remote diagnostics, and enhanced safety mechanisms offer significant benefits that can lead to cost savings, increased productivity, and better product protection.

While the initial investment may be higher, the long-term gains in terms of efficiency, reduced labor, and lower material waste can make the added expense worthwhile. Furthermore, features like predictive maintenance, data tracking, and IoT integration help future-proof your operations, ensuring that your equipment stays relevant in an ever-evolving industry.

For companies operating in specialized sectors or dealing with complex packaging needs, investing in these advanced features is not just a luxury—it's a necessity for staying competitive and maintaining operational efficiency. In the end, paying more for advanced features is often a smart decision, especially if you’re looking to optimize your packaging process and achieve long-term sustainability.