Automated Horizontal Stretch Wrapper

In today's fast-paced manufacturing landscape, efficiency is the key to success. One machine stands out as a game-changer in packaging solutions: the automated horizontal stretch wrapper. With its innovative design and operational advantages, this equipment has transformed industries by reducing costs and increasing throughput.

For businesses striving to optimize their packaging lines, adopting advanced machinery is no longer optional—it's essential. Whether handling fragile goods or bulky industrial products, the horizontal stretch wrapper provides a seamless balance between functionality and precision, ensuring your packages are secure and your workflow remains uninterrupted.

The rise of automation has ushered in new possibilities, but the question remains: how do you know this is the right machine for your needs? By diving into its features, benefits, and real-world applications, we’ll explore why it has become a cornerstone for modern packaging operations.

1. What Makes an Automated Horizontal Stretch Wrapper the Best Choice?

Key Features That Set It Apart

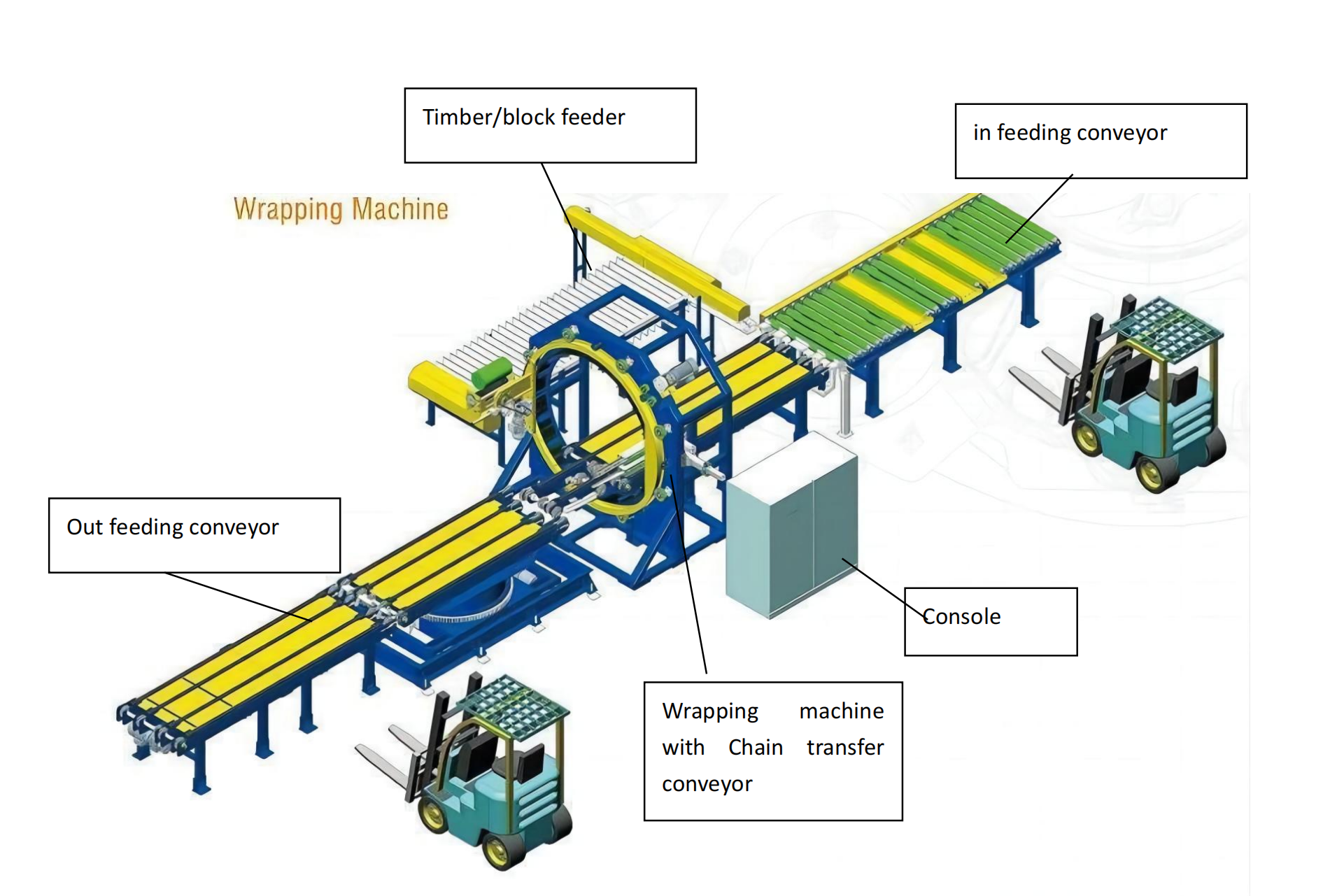

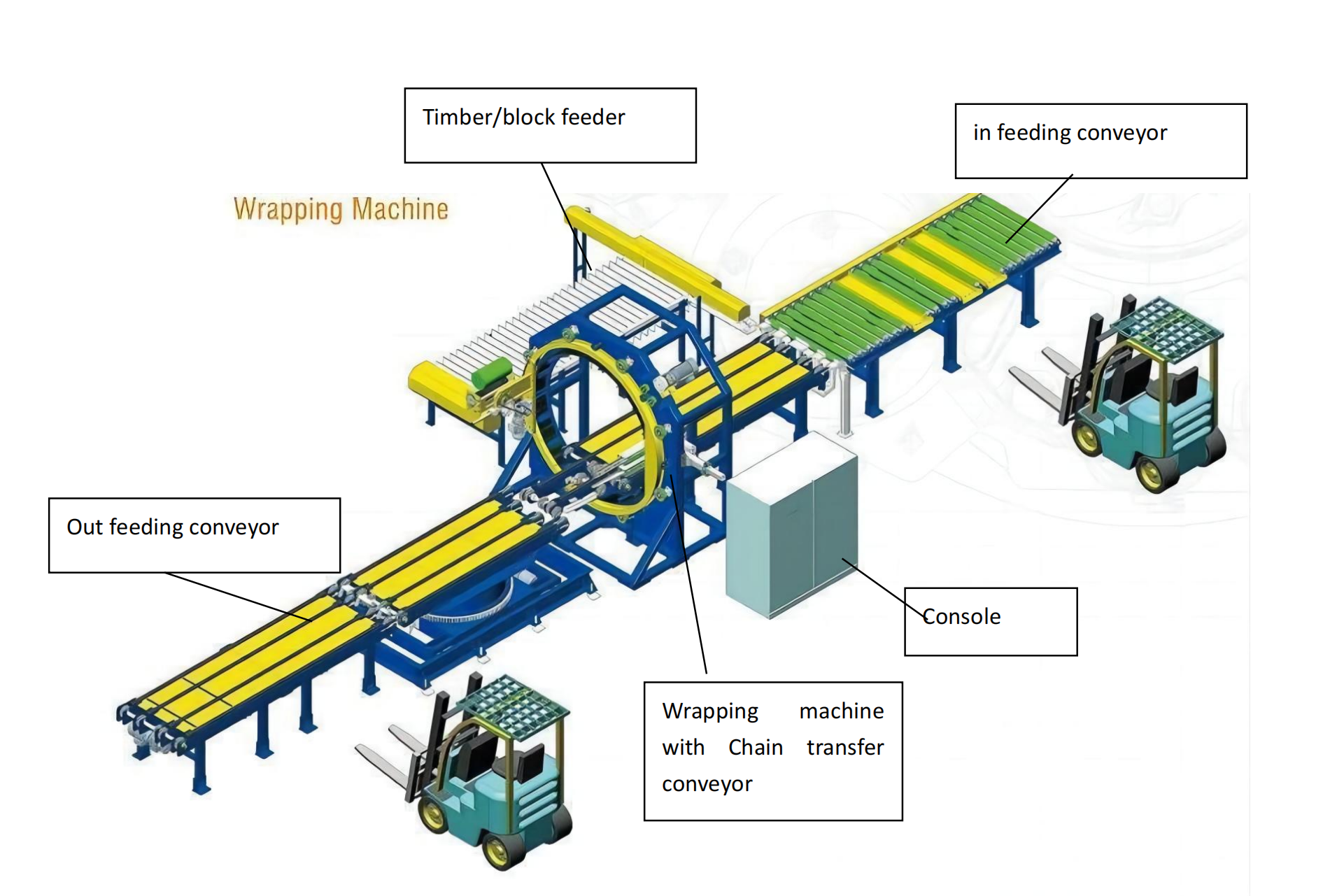

An automated horizontal stretch wrapper isn’t just another piece of machinery—it’s a transformative tool engineered for precision. Unlike manual or semi-automatic solutions, these machines come with intelligent controls, allowing for tailored wrapping processes based on product size, weight, and shape.

Features like variable wrapping speeds, programmable presets, and advanced tension controls ensure every package is optimally wrapped. Additionally, their compact design makes them space-efficient, even for facilities with limited floor space.

How Does It Simplify Packaging?

Efficiency is one of the most compelling benefits of automation. The horizontal stretch wrapper minimizes human intervention, reducing the likelihood of errors. It adjusts seamlessly to varying product dimensions, making it versatile across industries.

Its automated features ensure that even irregularly shaped items, like pipes or steel coils, are securely wrapped in a single pass. This not only saves time but also reduces material waste—two key factors in modern packaging strategies.

Real-Life Advantages of Automation

The benefits of investing in an automated system extend beyond speed. Consistency in packaging quality builds customer trust, while reduced labor dependency lowers operational costs. Imagine a production line that runs smoothly without constant manual intervention—a reality achieved with this technology.

Companies in logistics, steel manufacturing, and furniture production report significant reductions in damaged goods during transit after implementing automated horizontal stretch wrappers. Over time, these savings compound, delivering a higher return on investment (ROI).

2. How Can You Maximize ROI with This Equipment?

Initial Investment vs. Long-Term Benefits

While automated horizontal stretch wrappers require a substantial upfront investment, the long-term cost savings are undeniable. Reduced labor expenses, fewer product damages, and lower material waste quickly offset the initial expenditure.

Consider the alternative: manual wrapping processes are not only time-consuming but also inconsistent, leading to variable quality and higher material usage. Automation eliminates these inefficiencies, resulting in a streamlined workflow and higher output.

Ways to Reduce Operational Costs

Implementing an automated wrapper can directly impact operational expenses. Smart sensors and programmable controls reduce film usage by ensuring optimal tension and coverage. Moreover, these machines require minimal maintenance, further driving down costs.

For example, by optimizing film consumption alone, many businesses have reported material cost reductions of up to 20%. This improvement, coupled with decreased reliance on manual labor, results in a leaner, more cost-effective operation.

Practical Case Studies on Savings

A global logistics firm recently integrated horizontal stretch wrappers into its packaging lines. The result? A 35% increase in throughput and a significant reduction in damaged shipments. Another example comes from a furniture manufacturer, where transitioning to automation reduced their labor force by 40%, reallocating resources to other areas of production.

These success stories underscore how automation isn’t just an upgrade—it’s a strategic decision that pays dividends in efficiency and reliability.

3. How Can Automated Horizontal Stretch Wrappers Improve Workflow?

Enhancing Process Efficiency

Automation thrives on consistency, and horizontal stretch wrappers are no exception. By integrating these machines into a packaging line, businesses can eliminate bottlenecks caused by manual handling. The streamlined process allows for continuous operation, leading to higher productivity and reduced cycle times.

For instance, a manufacturing plant wrapping steel pipes manually may require 3–4 workers per shift. With an automated wrapper, the same task is completed faster with minimal oversight, freeing up labor for other high-value tasks.

Reducing Human Error in Packaging

Human error is a common challenge in manual packaging processes, often leading to insufficient wrapping or wasted material. Automated horizontal stretch wrappers solve this problem by ensuring precision and uniformity in every application.

Advanced machines feature intelligent control systems that monitor and adjust operations in real time. This minimizes the likelihood of material tearing or overuse, ultimately leading to cost savings and consistent product protection.

Adapting to Varying Product Dimensions

Whether you’re wrapping compact furniture or lengthy steel rods, an automated horizontal stretch wrapper adapts to the task. Customizable settings allow the machine to accommodate products of varying sizes and shapes without manual intervention.

This adaptability ensures that businesses can handle diverse product lines with a single solution, boosting flexibility and scalability.

4. How Do These Machines Enhance Workplace Safety?

Eliminating Hazardous Manual Tasks

Manual wrapping processes often expose workers to risks, such as repetitive strain injuries or accidents caused by mishandling heavy products. Automating these tasks with a horizontal stretch wrapper significantly reduces such hazards.

With features like automated loading, wrapping, and unloading, workers no longer need to manually handle bulky items. This creates a safer work environment while complying with workplace safety regulations.

Built-in Safety Features

Modern horizontal stretch wrappers are designed with safety in mind. Emergency stop buttons, motion sensors, and protective enclosures prevent accidents during operation. These features are essential in high-paced industrial environments where safety cannot be compromised.

Long-term Impact on Workforce Well-being

Beyond immediate safety improvements, automation contributes to the long-term well-being of workers. By reducing physically demanding tasks, employees are less likely to suffer from chronic injuries, leading to lower absenteeism and higher morale.

In industries like logistics or manufacturing, where worker safety directly impacts productivity, these benefits cannot be overstated.

Conclusion

[claim]

Automated horizontal stretch wrappers are more than just an investment in machinery—they’re a commitment to efficiency, safety, and quality.

From enhancing workflow efficiency to promoting workplace safety and delivering substantial cost savings, these machines provide unparalleled value to businesses across various sectors. As industries continue to evolve, adopting advanced packaging solutions like horizontal stretch wrappers will become essential for staying competitive.

Automation isn’t just about keeping up with industry standards; it’s about setting them. By investing in a horizontal stretch wrapper, you’re not only optimizing your operations but also securing the future of your business.