Negotiation Strategies for Horizontal Ring Wrapper for Bulk Material Packaging

Introduction: The Importance of Effective Negotiation in Packaging Equipment Procurement

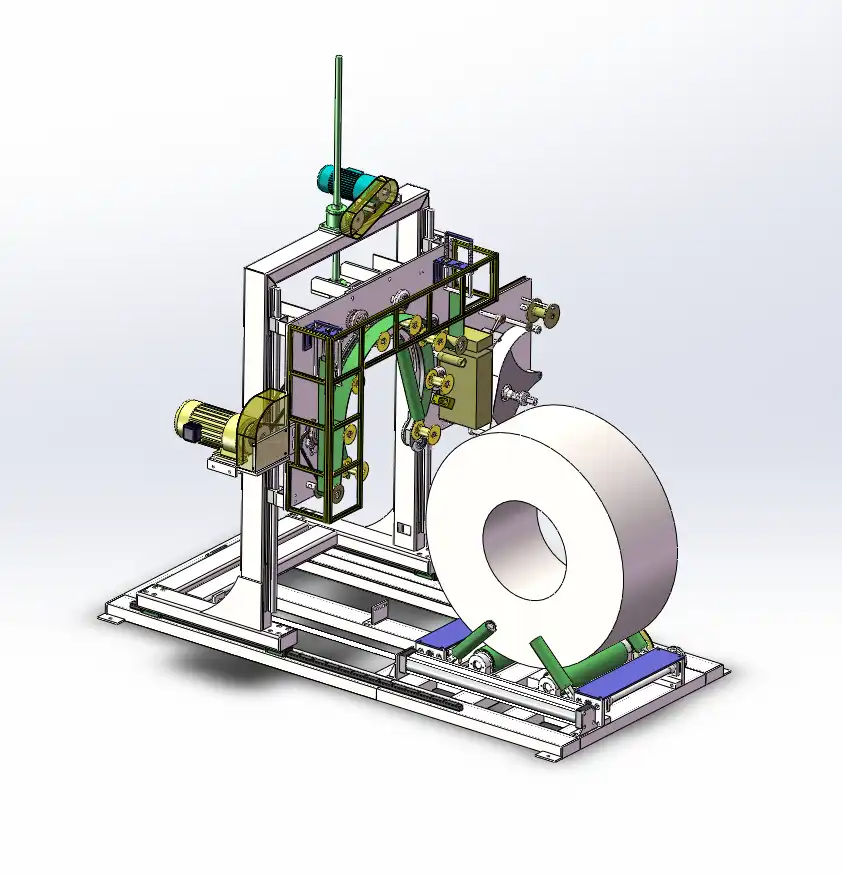

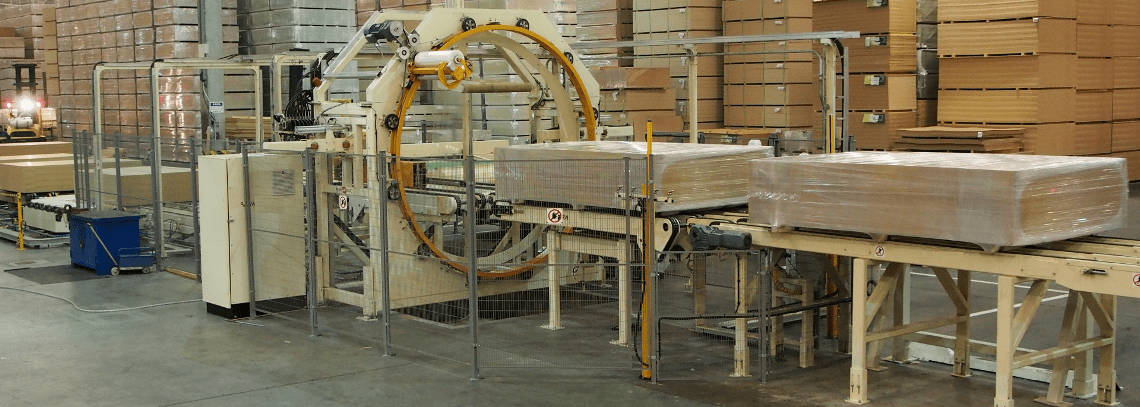

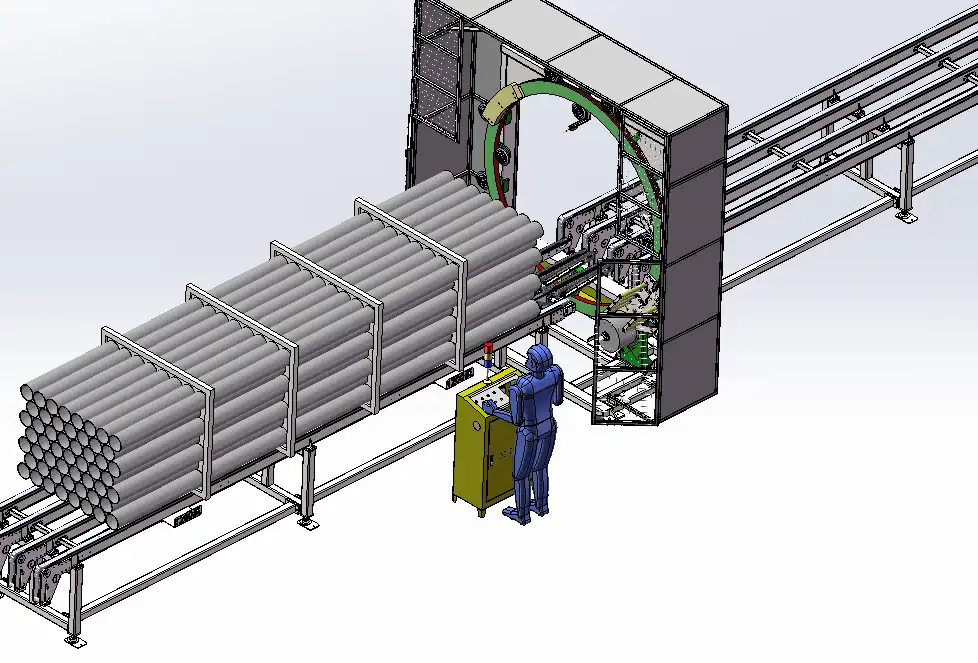

In today's fast-paced manufacturing and logistics industries, bulk material packaging is critical for safeguarding products during transit and ensuring operational efficiency. Among the most important packaging solutions for cylindrical and bulky materials is the horizontal ring wrapper, a highly efficient machine designed to wrap materials such as pipes, cables, steel coils, and other cylindrical products. These machines not only ensure safe and secure packaging but also contribute to reducing labor costs and improving productivity.

However, acquiring the right horizontal ring wrapper at an optimal cost requires more than just identifying the best machine. Effective negotiation strategies can significantly impact the total cost of ownership, including pricing, warranties, maintenance, and long-term operational efficiency. To make the most out of your investment, you need to approach supplier negotiations with a clear understanding of the equipment's features, market conditions, and your business's specific needs.

This article will provide in-depth negotiation strategies for acquiring a horizontal ring wrapper for bulk material packaging, focusing on how to secure the best possible deal while ensuring the machine meets your operational requirements. From understanding machine specifications to leveraging after-sales support, we will break down the key factors that can help you optimize costs without compromising on quality.

1. Understanding Horizontal Ring Wrapper Specifications

Why Technical Knowledge Matters in Negotiations

Before entering into any negotiations, it is essential to have a solid understanding of the technical specifications of the horizontal ring wrapper. This not only helps you evaluate the machine’s capabilities but also gives you the confidence to negotiate more effectively. Suppliers will likely present different models with varying features, such as wrapping speed, ring size, film compatibility, and load capacity. Knowing these details enables you to determine which features are essential for your operation and which may be unnecessary, giving you leverage to negotiate a more customized solution and potentially lower costs.

Key Features to Consider

-

Wrapping speed: The rate at which the machine wraps materials. For businesses handling large volumes, faster speeds equate to higher productivity.

-

Ring size: The diameter of the ring through which the materials pass. This is important depending on the size and shape of the materials being packaged.

-

Film compatibility: The types of wrapping film the machine can handle, such as stretch film or shrink wrap, which impacts material costs.

-

Durability and maintenance requirements: Look for machines with durable components to minimize long-term maintenance costs.

By understanding the essential technical features, you can negotiate more effectively for a machine that fits your specific needs while avoiding unnecessary features that could drive up costs.

2. Leveraging Market Research to Gain Pricing Leverage

Analyzing Current Market Trends

A key part of any negotiation strategy is market research. Before entering into discussions with suppliers, it's crucial to analyze the current market for horizontal ring wrappers. This includes understanding the average pricing for different models, as well as factors such as demand trends, supplier competition, and potential seasonal discounts.

Keep in mind that the packaging equipment market is subject to fluctuations in supply and demand. For instance, during periods of high demand, such as peak industrial seasons, prices may rise. Conversely, during slower periods, suppliers may be more open to negotiation as they seek to maintain sales volumes.

Comparing Multiple Suppliers

One of the most effective ways to secure a competitive price is to obtain quotes from multiple suppliers. When suppliers know they are competing for your business, they may offer more competitive pricing or additional incentives, such as extended warranties, discounted maintenance contracts, or reduced shipping costs. Be sure to evaluate multiple options, and don't hesitate to ask each supplier to match or beat competing offers.

Also, consider negotiating with suppliers from different regions. In some cases, international suppliers may offer more attractive terms due to currency exchange rates or lower production costs.

3. Negotiating Beyond the Price Tag: Total Cost of Ownership (TCO)

The Importance of TCO in Negotiation

While the upfront price of the horizontal ring wrapper is an important consideration, it's equally critical to negotiate based on the Total Cost of Ownership (TCO). TCO encompasses not just the purchase price but also long-term costs such as maintenance, repairs, energy consumption, and film usage. By negotiating with TCO in mind, you can secure a deal that minimizes operational costs over the lifespan of the machine.

Maintenance Contracts and After-Sales Support

One of the most overlooked aspects of equipment procurement is the cost of maintenance and repairs. During the negotiation process, it's essential to secure a maintenance contract that covers regular servicing and technical support. This ensures that your machine continues to operate efficiently, reducing the likelihood of costly downtime due to mechanical failure.

Additionally, ask about the availability of spare parts and whether the supplier offers local support or requires long wait times for international parts to be shipped. A good supplier should offer a comprehensive after-sales support package that includes training, troubleshooting, and emergency repairs. This not only helps minimize downtime but also adds value to your purchase.

4. Negotiating Flexible Payment Terms

Customizing Payment Plans

Many businesses face cash flow challenges when making significant capital investments in equipment like a horizontal ring wrapper. Rather than paying the full amount upfront, consider negotiating flexible payment terms. Some suppliers may offer payment plans that allow you to spread out the cost over several months or years, easing the financial burden on your business.

Some common payment options include:

-

Leasing: Pay a monthly fee to use the machine, with the option to buy it at the end of the lease term.

-

Deferred payment: Negotiate a deferred payment schedule where the full amount is due after a set period, giving your business time to generate revenue before making the full payment.

-

Installments: Arrange to pay in installments, with a portion paid upfront and the remainder spread over time.

Leveraging Down Payments

Another tactic for optimizing payment terms is negotiating a lower down payment. While some suppliers may require a significant deposit upfront, negotiating a lower down payment allows you to retain more working capital. This can be especially useful for businesses that need to keep cash on hand for other operational expenses.

By negotiating flexible payment terms, you can better align your financial commitments with your cash flow, ensuring that the investment in a horizontal ring wrapper doesn't strain your finances.

5. Securing Warranties and Service Agreements

Importance of Warranties

A comprehensive warranty is one of the most valuable elements to negotiate when purchasing a horizontal ring wrapper. Warranties protect your investment by covering the cost of repairs or replacements for defective parts, ensuring that your machine remains operational without additional out-of-pocket expenses.

When negotiating a warranty, aim for coverage that includes the following:

-

Parts and labor: Ensure both are covered for an extended period.

-

Comprehensive service: This should cover both scheduled maintenance and emergency repairs.

-

Long warranty periods: Try to secure warranties that last at least two to three years, with an option to extend further.

A longer warranty period gives you peace of mind, ensuring that the machine will continue to operate smoothly without incurring costly repair bills shortly after purchase.

Service Agreements for Long-Term Reliability

In addition to warranties, negotiate a service agreement that covers routine maintenance and ensures the machine is regularly serviced to prevent unexpected breakdowns. Some suppliers offer extended service agreements, which can be particularly beneficial for businesses operating in high-demand environments.

A well-negotiated service agreement can extend the life of your horizontal ring wrapper, ensuring it continues to perform at peak efficiency over the long term.

6. Customization and Scalability for Future Needs

Tailoring the Machine to Your Needs

During negotiations, it's important to discuss any customization options that the supplier can provide. Horizontal ring wrappers are used to package a wide range of materials, and having the flexibility to customize the machine ensures that it meets your specific packaging needs. Whether it's modifying the size of the ring, adjusting the wrapping speed, or integrating additional automation features, negotiating for customizable components allows you to optimize the machine for your operational processes.

Planning for Scalability

As your business grows, your packaging needs may evolve. A smart negotiation strategy should include a discussion of the machine’s scalability. For example, can the machine handle higher volumes in the future? Can additional features be added later to increase its efficiency or productivity?

Negotiating a machine that can be upgraded or expanded as your business grows ensures that the investment remains valuable over time and can accommodate future demands without requiring a complete replacement.

Conclusion: Effective Negotiation for Long-Term Value

Negotiating the purchase of a horizontal ring wrapper for bulk material packaging involves more than just securing a competitive price. By focusing on the total cost of ownership, understanding the machine’s specifications, and securing favorable warranties and service agreements, businesses can maximize the value of their investment. Additionally, negotiating flexible payment terms and ensuring that the machine can be customized and scaled to meet future needs will ensure that the investment continues to pay off over the long term.

Approaching supplier negotiations with a clear strategy will allow you to secure a cost-effective solution that improves operational efficiency, enhances product protection, and provides long-lasting reliability.

.jpg)