Modle: Wire coil wrapping machine-FPW-500

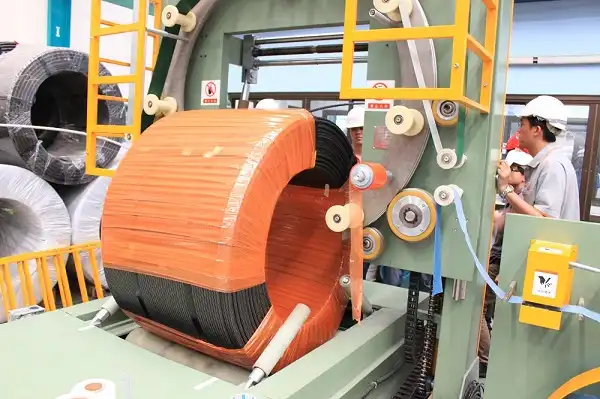

The FPS-500 is a steel wire wrapper designed for coils 100-500 mm in width. Coils are loaded and unloaded from the top of the machine via crane. The wrapping process travels through the coil ID at 360 degrees. This flexible, low-maintenance machine can replace 3-4 workers, packing at high speeds while producing neatly wrapped, seaworthy packages. With an affordable price and 1-2-year ROI, the FPS-500 is an ideal wire packaging solution.

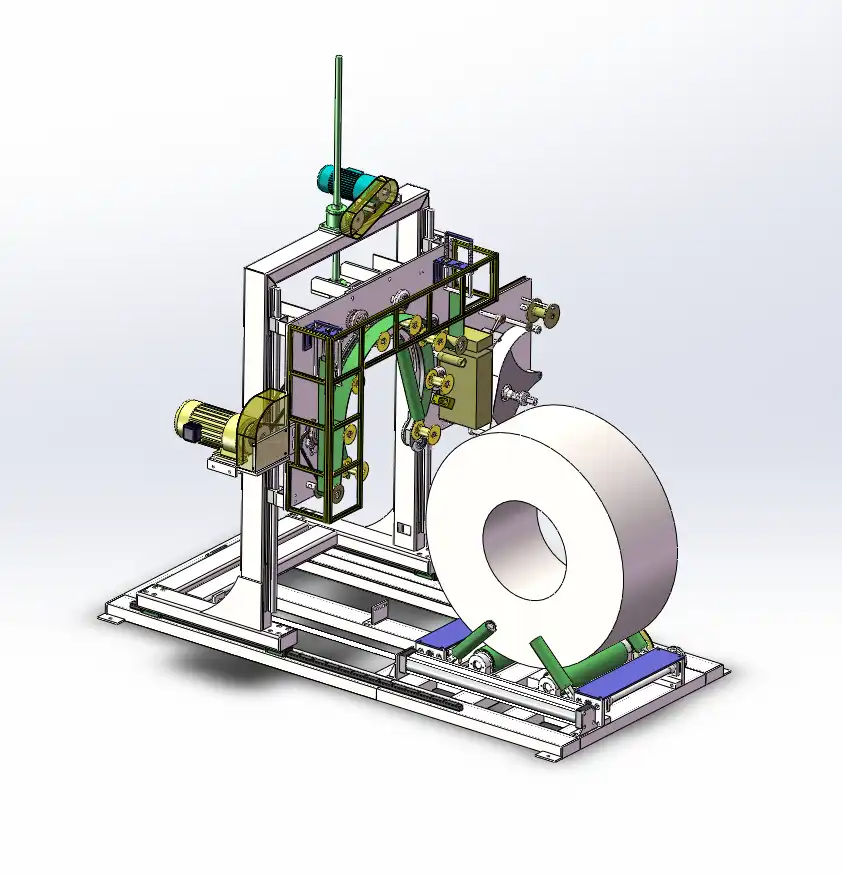

The FPW-500 series steel wire wrapper features a trolley for easy coil loading/unloading. A Siemens PLC provides precise control of wrapping motions with minimal maintenance. Premium electrical components enable high-speed, gentle wrapping and high reliability at low operating and maintenance costs.

Features:

1.Automatic for wire coil wrapping with packing material length checking.

2.Packing material next by the wrapping station type.

3.Supportive roller PU covering & passive friction wheels and integral mould structure devices antiskid and safe, making package object more stable and tidier.

4.Different packing materials might be adopted.

5.Main board up and down adjustment by motor with gear.

6.Overlap extent and tension degree of packing material could be regulated as the customers’ need.

7.The mechanical hand device can be used to feeding & cutting packing material automatically.

8.Trolley in & out the wrapping station with procising position automatic.

9. Easy operation by non skilled operator

10.Special cutter with cylinder, could cut various kinds of packing materials.

|

Coil Packing Machine

|

FPW-500

|

|

Voltage (V/Hz)

|

380v 50Hz 3Phase

|

|

Power (KW)

|

3.5kw

|

|

Steel wire coil ID(mm)

|

300-700

|

|

Steel wire coil OD(mm)

|

700-1300

|

|

Steel wire coil width(mm)

|

50-500mm

|

|

Steel wire coil Weight(Kg)

|

40-1500kg

|

|

Packing material

|

PVC/LDPE/LLPE/PAPER/HDPE

ID:50mm

OD:100-450mm

Width:100-120mm

|

|

Overlapping rate

|

10%-90%

|

|

Air supply.

|

4-6kgf/m2

|

The highly versatile FPW-500 can wrap steel wire coils of all dimensions.

A crane loads the stationary coil as the wrapping mechanisms operate.

Included accessories such as a C-hook and mobile coil trolley facilitate moving coils to and from the wrapper, coil tipper, or tilter.

Limited sensors on the packing station monitor coil positioning as the machine glides back and forth on floor rails.

This allows the FPW-500 to service multiple packing stations, with support rolls that can be stationary or truck-mounted for mobility.

By customizing the coil handling equipment and support rolls, the FPW-500 can be outfitted for unique packaging workflows and scaled to meet high-volume operation demands.