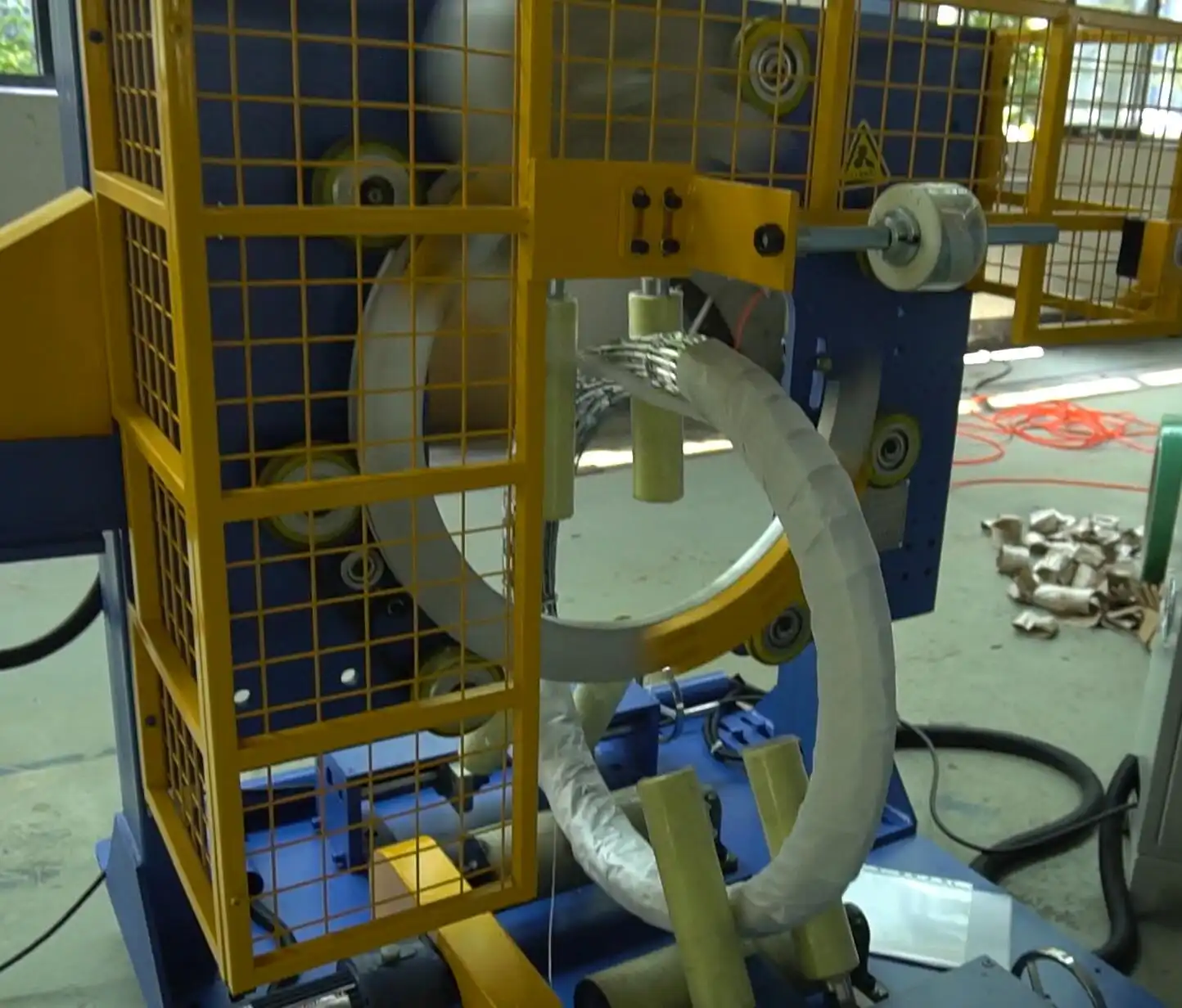

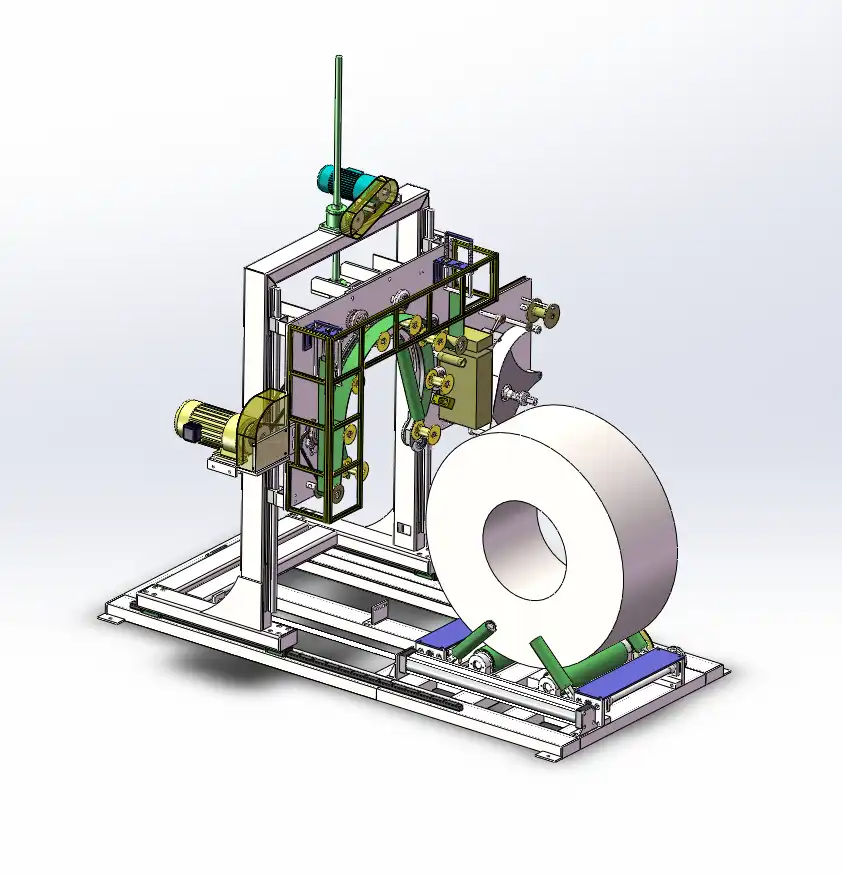

Razor wire wrapping machine

1) Benefit:

-

Designed in modules for ease of upkeep

-

Exceptional productivity in coil packaging

-

Vast suitability; custom sizing guarantees tailored solutions

-

No hazard of product harm or danger to personnel

-

Extraordinarily low costs of supplies and power

-

The equipment operates at a reduced din

-

Rapid configuration needed

-

Converter enables regulated packaging pace

-

An integrated quick-convert dispenser stocks the bundling material

The machine was special made for razor wire coil packing that is able cover the stretch film inside layer. And wrapping the paper, woven outside layer for protecting the package.

2) Basic characteristics:

1. Excellent collections. Well-known brands are adopted for main components.

2. The overlap of packing tape can be adjusted by inverter.

3. Ring speed is adjustable by frequency inverter.

4. Roller speed is adjustable by frequency inverter.

5. Level height of turning ring can be adjusted for different coils’ size.

8.Distance of up & down protective rollers can be adjusted for package.

9.The distance between protective rollers is adjustable for different size of coils.

10. Packing tape tension can be adjusted by special brake device.

11. Difference packing material can be choosing.

12. Supporting & protective rollers are covered by polyurethane for protect the surface of the coils.

13. Up and down supporting rollers are available.

14. Special draw back device is used to make sure the well and tightness package for big & small size of coils.

15. Separate electrical box & control panel for safe operation and technical testing.

electrical cabinet

15.Operation buttons are in Chinese and English.

16. Indicator lamp alarms when trouble occurs.

17. Soft start and stop for safe operation and protect the surface of coils.

18. Packing position reset.

19. Guardrail is for safe operation.

20. Friction between wheel and ring is adjustable.

21. Tape cutting time can be set on the control panel for tape cutting automatically.

22. Tape cutter is controlled by the cylinder.

23. Material fixe next to the wrapping station for wrapping.

3) Option:

Ring level adjustment by motor

Logo tape tapping device

4) Technical parameter:

Machine Model

|

FPW300-W

|

Object weight

|

10-100kg

|

Package width

|

200-300mm OD = 700-950 mm, ID = 450-700 mm OD-ID<300mm

|

Roller Speed

|

2-4m/min

|

Wrapping speed

|

20-35sec/pcs

|

Rotating speed

|

40-100r/min

|

Overlap scope

|

20%-90%

|

Power output

|

app. 1.5kw

|

Power voltage

|

380v/50Hz, 3Phase 5 wires

|

Packing material

|

Crepe paper / knit belt / compound paper / HDPE

ID: 55mm OD: 300-450mm Width:70- 90mm

|