Reducing Repetitive Labor in Six-Sided Horizontal Orbital Stretch Wrapper for Board: How Automation Cuts Workload

In manufacturing and logistics, repetitive labor is one of the leading causes of worker fatigue, inefficiency, and higher operational costs. The use of advanced six-sided horizontal orbital stretch wrappers is revolutionizing the way businesses package boards and panels. By automating the wrapping process, these machines not only increase packaging speed but also significantly reduce the amount of manual labor required. This shift towards automation helps companies streamline their operations, improve productivity, and cut overall workload.

This article explores how automation in six-sided horizontal orbital stretch wrappers reduces repetitive labor and improves operational efficiency in board packaging. We will analyze the key benefits of automation, the challenges it addresses, and how investing in the right technology can positively impact your business.

1. Understanding the Six-Sided Horizontal Orbital Stretch Wrapper for Boards

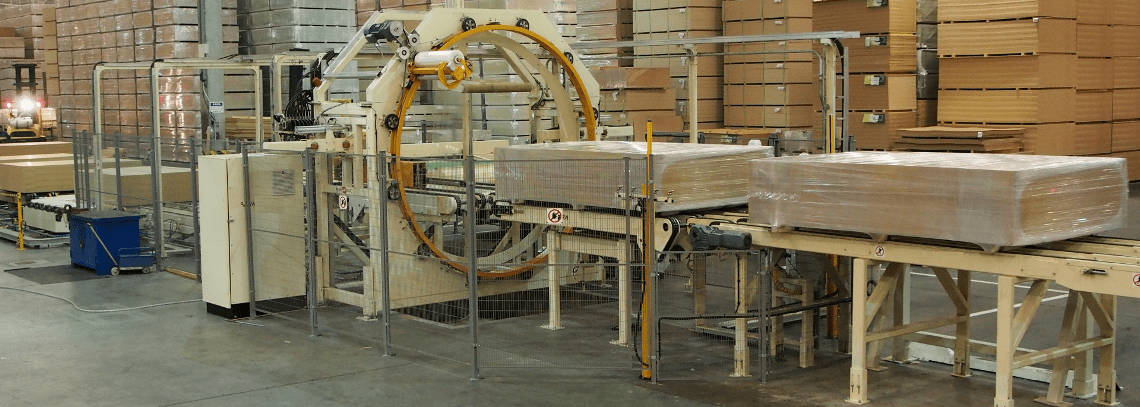

A six-sided horizontal orbital stretch wrapper is a specialized machine designed to wrap flat boards, panels, or similar products from all six sides in one continuous process. These machines use stretch film to secure the product, providing protection against dust, moisture, and damage during transport or storage.

The design of the machine allows it to wrap products efficiently and consistently, eliminating the need for manual handling or adjustment during the wrapping process. The six-sided wrapping ensures complete coverage, which is essential for protecting fragile or valuable products.

2. The Impact of Repetitive Labor in Manual Packaging

Manual packaging processes, especially for large, heavy, or flat items like boards, can be highly repetitive and labor-intensive. Workers are required to handle the products multiple times, apply the packaging material manually, and ensure that the product is securely wrapped. This leads to several challenges:

2.1 Worker Fatigue and Injuries

Repetitive manual tasks can lead to worker fatigue, which increases the likelihood of errors, injuries, and reduced productivity. Lifting, bending, and applying packaging materials repeatedly can cause strain on the body, resulting in musculoskeletal disorders over time.

2.2 Inconsistent Packaging Quality

When relying on manual labor, the quality of packaging can vary from worker to worker and from product to product. Inconsistent film tension, coverage, and application can lead to inadequate protection for the product, resulting in higher rates of damage during transportation.

2.3 High Labor Costs

Manual packaging processes require more workers, which drives up labor costs. Additionally, the time spent on each product is longer, reducing overall efficiency and increasing the cost per unit packaged.

3. How Automation in Six-Sided Orbital Wrapping Reduces Workload

Automating the packaging process with a six-sided orbital stretch wrapper drastically reduces the workload associated with repetitive manual labor. Here are some of the key ways that automation cuts down on repetitive tasks and improves operational efficiency.

3.1 Elimination of Manual Wrapping

With automation, workers no longer need to manually apply stretch film to the boards. The machine handles the entire process, automatically wrapping the product from all six sides without the need for human intervention. This reduces the physical strain on workers and allows them to focus on other tasks, increasing overall productivity.

3.2 Consistent Packaging Quality

One of the key advantages of automation is consistency. Automated machines apply the stretch film uniformly, ensuring that every board or panel is wrapped to the same standard. This results in better product protection and fewer damaged items during shipping, reducing the need for returns or replacements.

3.3 Increased Packaging Speed

Automated wrapping machines can package boards much faster than manual labor. A six-sided orbital wrapper can wrap a product in a fraction of the time it would take a human worker. This increased speed translates into higher throughput, allowing businesses to package more products in less time and meet demand more efficiently.

4. Key Technologies Behind Automation in Orbital Stretch Wrappers

Several advanced technologies contribute to the efficiency and labor-saving benefits of six-sided orbital stretch wrappers. Understanding these technologies can help businesses make informed decisions when investing in packaging automation.

4.1 Pre-Stretch Film Technology

Pre-stretch film technology is one of the most important innovations in modern orbital wrapping machines. This technology stretches the film before it is applied to the product, reducing the amount of material needed while maintaining a tight and secure wrap. By using less material, businesses can reduce packaging costs and minimize waste.

Pre-stretch technology also ensures that the film is applied evenly and with the correct tension, further improving packaging quality and reducing the risk of product damage.

4.2 Automated Tension Control

Automated tension control is another key feature of modern stretch wrappers. The machine automatically adjusts the tension of the film to suit the size and shape of the board being wrapped, ensuring that the product is neither over-wrapped nor under-wrapped. This level of precision helps reduce material waste and ensures that each board is protected without risking damage from too much tension.

4.3 Smart Sensors and Product Detection

Many advanced orbital wrapping machines are equipped with smart sensors that detect the size, shape, and position of the board as it moves through the wrapping process. These sensors help the machine automatically adjust its settings to match the specific dimensions of the product, ensuring optimal wrapping without the need for manual input.

The use of smart sensors reduces human error and ensures that the machine can handle a variety of board sizes and shapes with ease, making the packaging process more efficient and versatile.

5. Benefits of Reducing Repetitive Labor with Automation

The shift to automated packaging solutions, such as six-sided orbital stretch wrappers, offers numerous benefits that go beyond simply reducing labor. By automating the process, businesses can realize significant improvements in efficiency, cost savings, and worker safety.

5.1 Enhanced Worker Safety

Reducing the need for manual handling during the packaging process helps improve worker safety. Automated machines take over the physically demanding tasks, reducing the risk of injuries caused by repetitive movements or heavy lifting. Workers are less likely to experience strain-related injuries, leading to a safer work environment.

5.2 Lower Operational Costs

Automation reduces the number of workers needed to operate the packaging line, leading to lower labor costs. Additionally, the increased speed and efficiency of the automated system allow businesses to package more products in less time, further reducing costs per unit.

5.3 Reduced Product Damage

Consistent and uniform wrapping provided by automated machines results in fewer instances of product damage during transportation. This helps reduce the costs associated with returns, replacements, and customer dissatisfaction, while also protecting the brand's reputation for delivering high-quality products.

6. Common Challenges in Implementing Automation and How to Overcome Them

While automation offers numerous benefits, implementing automated packaging systems is not without its challenges. Businesses need to carefully plan the transition to ensure a smooth and successful integration of new technologies.

6.1 Initial Investment Costs

One of the main challenges in adopting automated packaging systems is the initial investment cost. Automated machines can require significant upfront capital, which can be a barrier for some businesses. However, the long-term cost savings from reduced labor and increased efficiency often outweigh the initial investment.

To overcome this challenge, businesses can explore financing options or look for government incentives that support automation and innovation.

6.2 Operator Training

Although automated machines reduce the need for manual labor, they still require skilled operators to manage and maintain them. Implementing automation without proper operator training can lead to operational issues and downtime.

Businesses should invest in comprehensive training programs to ensure that their operators are fully capable of running and maintaining the machines. This includes understanding machine settings, troubleshooting common issues, and performing routine maintenance.

6.3 Integration with Existing Systems

Integrating a new automated wrapping machine into an existing production line can present logistical challenges. Businesses need to ensure that the new machine can work seamlessly with their current workflow, from product handling to storage and shipping.

Working with experienced suppliers who offer installation support and system integration services can help minimize disruptions and ensure a smooth transition to automation.

7. Choosing the Right Automated Wrapping Solution for Your Business

Selecting the right six-sided horizontal orbital stretch wrapper for your business involves evaluating your specific packaging needs and operational goals. Here are some key factors to consider when choosing an automated wrapping solution:

7.1 Product Size and Shape

The size and shape of the boards you need to package will determine the specifications of the machine. Ensure that the machine you choose can accommodate the largest and heaviest items in your inventory without sacrificing speed or quality.

7.2 Production Volume

High-volume operations will benefit from fully automated machines capable of handling continuous packaging without operator intervention. For smaller businesses, semi-automated machines may offer a more cost-effective solution while still providing significant labor savings.

7.3 Customization Options

If your business handles a variety of product sizes and shapes, look for machines that offer customizable settings for film tension, wrapping speed, and product positioning. This flexibility ensures that you can package different products without the need for multiple machines.

8. Conclusion

Incorporating automation in the form of six-sided horizontal orbital stretch wrappers is a smart investment for businesses looking to reduce repetitive labor, enhance efficiency, and improve packaging quality. By automating the wrapping process, companies can eliminate the physical strain of manual packaging, lower operational costs, and ensure consistent, high-quality protection for their products.

With the right machine in place, businesses can not only streamline their packaging operations but also create a safer, more efficient work environment. Automation is the key to cutting the workload in board packaging and positioning your business for long-term success.