Horizontal Stretch Wrappers For Sale

Horizontal stretch wrappers are transforming the way industries manage their packaging needs. These machines combine innovation and efficiency to optimize operations, offering tailored solutions for a wide range of applications. Whether you’re packaging delicate materials or heavy industrial products, horizontal stretch wrappers deliver unmatched reliability and protection.

Selecting the right horizontal stretch wrapper for your business can be a game-changer. From ensuring the safety of goods during transit to reducing packaging waste, these machines provide an essential tool for scaling operations. But how do you navigate the options to find the perfect fit?

The transition to automated wrapping solutions isn’t just a trend; it’s a strategic move toward operational excellence. Let’s delve into the essential aspects of horizontal stretch wrappers, explore the technology, and uncover why now is the best time to invest in these systems.

[claim] Horizontal stretch wrappers not only enhance packaging efficiency but also contribute to sustainability and cost-effectiveness, making them indispensable for modern businesses.

1. Why Should You Invest in a Horizontal Stretch Wrapper?

1.1 The demand for automation in packaging

The rise of e-commerce and global trade has placed immense pressure on businesses to optimize their packaging processes. Horizontal stretch wrappers cater to this demand by offering unparalleled efficiency, ensuring goods are secured for transit while reducing manual labor.

Automation is no longer a luxury but a necessity for businesses looking to scale. These machines bridge the gap between production and logistics, enabling seamless operations.

1.2 Financial and operational benefits

Investing in a horizontal stretch wrapper translates to tangible benefits. Businesses experience reduced material waste, improved productivity, and enhanced safety standards. Additionally, the cost savings from streamlined processes often offset the initial investment within months.

1.3 Broad industry applications

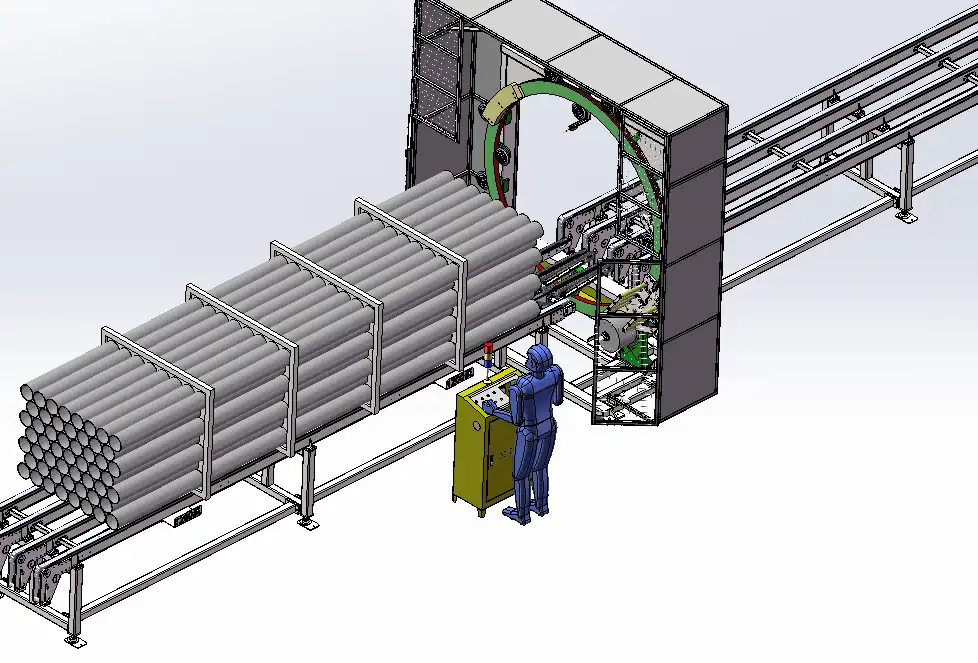

From manufacturing and distribution to agriculture and retail, the versatility of horizontal stretch wrappers ensures they meet the diverse needs of industries. Whether wrapping pipes, timber, or textiles, these machines adapt to various dimensions and weights, providing a universal packaging solution.

Horizontal stretch wrappers excel in environments that demand consistency and precision, making them a cornerstone of industrial packaging strategies.

2. How Do Horizontal Stretch Wrappers Improve Efficiency?

2.1 Enhancing speed without compromising quality

Efficiency is a hallmark of horizontal stretch wrappers. These machines operate at high speeds, significantly outpacing manual wrapping methods. Despite the increased throughput, they maintain superior wrapping consistency, ensuring every package is securely enclosed.

By eliminating bottlenecks in the packaging line, businesses can focus on scaling operations without worrying about delays or compromised quality

2.2 Reducing material waste and environmental impact

Traditional wrapping methods often lead to excess material usage. Horizontal stretch wrappers utilize pre-stretch film technology, minimizing waste while ensuring maximum coverage. This not only saves costs but also aligns with sustainability goals, an increasingly important consideration for businesses today.

2.3 Streamlining labor and operational demands

With these machines, the need for extensive manual labor is drastically reduced. Employees can redirect their focus to other critical tasks, enhancing overall operational efficiency. Moreover, the intuitive design of most horizontal stretch wrappers ensures quick training and minimal downtime.

Efficiency gains extend beyond the packaging line, as improved workflows often result in better inventory management and faster shipping times.

3. What Are the Key Features to Look for in a Horizontal Stretch Wrapper?

3.1 Advanced automation options

Automation is at the heart of modern horizontal stretch wrappers, but not all machines are created equal. Look for models with programmable logic controllers (PLCs), touch-screen interfaces, and customizable settings. These features ensure precise control over wrapping parameters, adapting effortlessly to different products and packaging needs.

Automation doesn’t just improve efficiency—it empowers operators with consistent, repeatable results that reduce errors and waste.

3.2 Compatibility and flexibility

One of the most critical factors when selecting a horizontal stretch wrapper is its compatibility with your existing production line. Machines that can handle a wide range of product sizes, shapes, and weights offer unmatched flexibility.

Machines with modular designs provide even greater adaptability, allowing for seamless upgrades or adjustments as your business evolves. This ensures you’re investing in a future-proof solution.

3.3 Durability and safety enhancements

A durable machine is a cost-effective machine. Look for rugged construction materials, corrosion-resistant components, and designs that prioritize easy maintenance. Additionally, safety features like emergency stop buttons, interlocked doors, and automated film cutters enhance operator protection.

Durability combined with advanced safety measures ensures long-term reliability and compliance with industry standards.

4. How to Ensure Long-Term Value from Your Horizontal Stretch Wrapper?

4.1 Choosing the right supplier

Partnering with a reputable supplier is critical to maximizing the value of your investment. Reliable manufacturers provide high-quality machines, offer warranties, and deliver robust after-sales support. Research customer reviews, case studies, and testimonials to identify trusted suppliers.

Suppliers who offer training and ongoing maintenance services further enhance the long-term efficiency of your horizontal stretch wrapper.

4.2 Maintenance and optimization

Regular maintenance is essential to keeping your machine in peak condition. Develop a preventative maintenance schedule, including inspections, lubrication, and component replacements. Optimization efforts, such as adjusting wrapping speeds and upgrading software, can further boost performance.

Proactively maintaining your equipment reduces unexpected downtime and extends its lifespan, ensuring you reap maximum benefits from your investment.

4.3 Scalability for future needs

Investing in a scalable solution is essential for growing businesses. Horizontal stretch wrappers with modular designs and upgradable features allow you to adapt to changing demands without replacing the entire system.

Choosing a machine that can handle increasing workloads or integrate with advanced technologies ensures your operations remain efficient and competitive for years to come.

Conclusion

[claim] Horizontal stretch wrappers are more than just packaging machines—they’re strategic tools for businesses aiming to boost efficiency, reduce waste, and achieve sustainability goals. By investing in the right machine and prioritizing long-term maintenance, companies can ensure their operations remain resilient and future-ready.

Whether you’re looking to optimize your current processes or explore new packaging solutions, horizontal stretch wrappers offer a clear path to operational success. With the right features, supplier, and maintenance strategy, these machines will deliver unmatched value for your business.