Customizable Features in Horizontal Orbital Wrappers: Tailoring the Machine to Your Timber Wooden Packing

When it comes to the packaging of timber and wooden products, having the right equipment can make a significant difference in efficiency, product protection, and cost-effectiveness. The horizontal orbital wrapper is one such machine that has become increasingly popular across industries dealing with heavy or large wooden products. Its ability to wrap items horizontally, combined with its customizable features, makes it an ideal solution for businesses seeking to improve their timber packing processes.

In this article, we'll explore the various customizable features available in horizontal orbital wrappers, particularly focusing on how these features can be tailored to meet the specific requirements of timber and wooden packing. From enhanced material handling to automation options, we'll break down how the right customization can optimize your operations.

1. Introduction to Horizontal Orbital Wrappers

A horizontal orbital wrapper is a specialized packaging machine designed to wrap large or long items, such as wooden beams, panels, or boards, using stretch film. Unlike traditional wrapping machines, which wrap products vertically, this machine operates horizontally, making it particularly suitable for timber and wooden packing.

These machines are highly valued for their ability to protect products during storage and transportation by providing a secure, weather-resistant layer of protection. As with any packaging equipment, the efficiency and effectiveness of a horizontal orbital wrapper can be further enhanced by integrating customizable features that align with your specific packing needs.

2. Why Customization Matters in Timber Wooden Packing

Every timber or wood-based business has unique requirements based on the size, shape, and type of wood products they handle. For example, hardwood beams may require different wrapping techniques compared to plywood panels. This is where customization becomes essential. By incorporating tailored features into your horizontal orbital wrapper, you can ensure that the machine works perfectly with the types of products you're packaging.

Customized features not only increase the flexibility of the machine but also enhance productivity and reduce material waste. When tailored to specific needs, these machines minimize the risk of product damage and ensure that the wrapping process is as efficient as possible.

3. Customizable Film Delivery System

One of the most important customizable features in a horizontal orbital wrapper is the film delivery system. Timber and wooden products often have varying dimensions, meaning a standard film application may not always provide optimal coverage. Customizing the film delivery system allows businesses to adjust the amount of stretch film used for different product types.

For example, a dual-film delivery system can be implemented to provide additional layers of protection for larger or heavier wooden products. This feature ensures that the wrapping is tight and secure, reducing the risk of the product shifting during transport. Furthermore, customizable film tension settings help in minimizing film usage, which reduces overall packaging costs.

4. Adjustable Machine Size for Varied Product Dimensions

Another critical customization option for horizontal orbital wrappers is the ability to adjust the machine’s size to accommodate a wide range of product dimensions. Timber products come in various sizes, from long wooden beams to small wooden crates. Investing in a customizable machine frame ensures that your wrapper can handle both large and small items without requiring a separate machine for each product size.

In addition, the flexibility to adjust the height and width of the machine's wrapping area makes it easier to wrap irregularly shaped wooden products. This feature is especially beneficial for businesses that deal with bespoke timber products, as it allows for greater versatility in the packaging process.

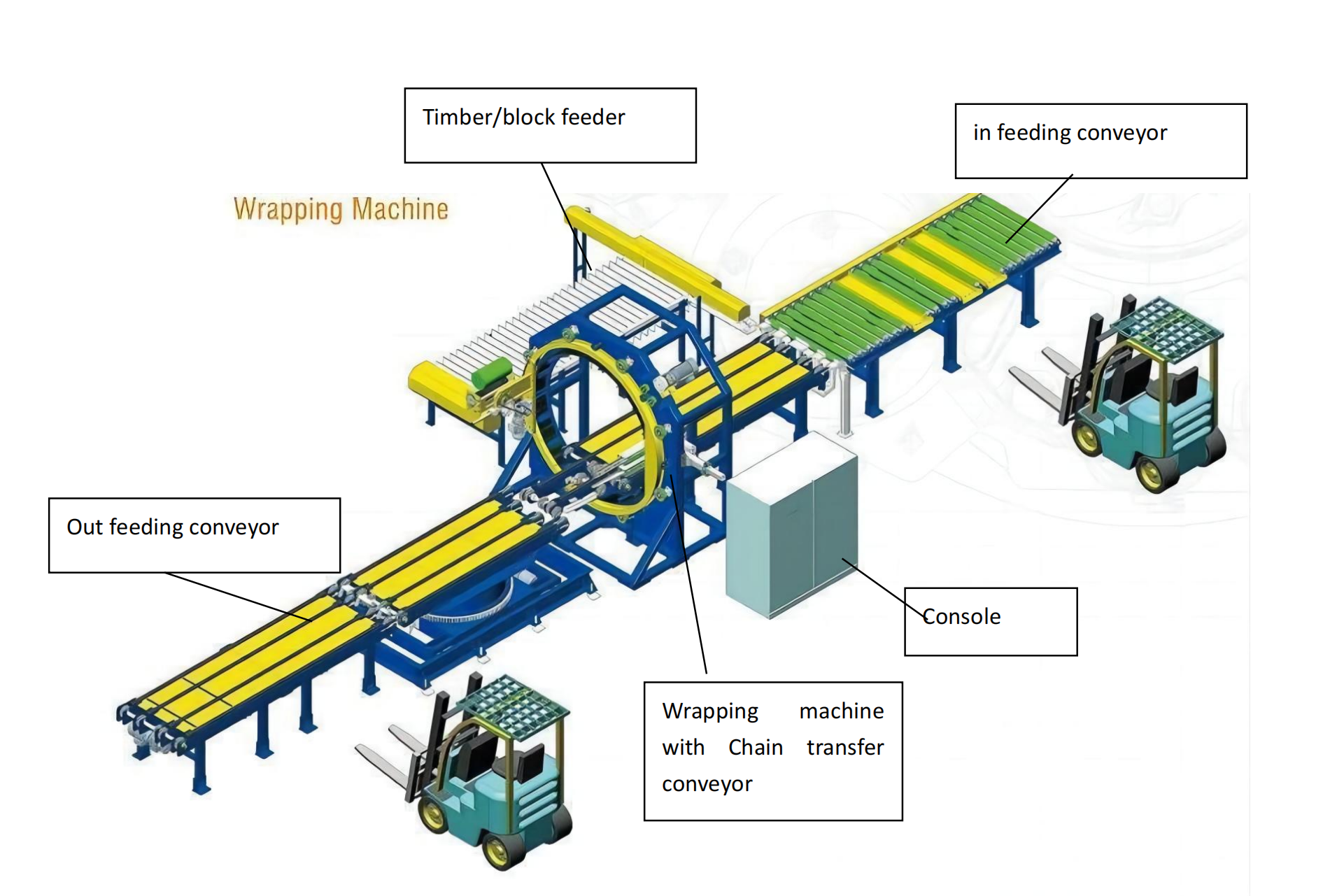

5. Integration with Material Handling Systems

Efficient packaging goes hand in hand with effective material handling. Many horizontal orbital wrappers can be customized to integrate with existing material handling systems such as conveyors, automated loaders, and sorting systems. This integration streamlines the packaging process by ensuring that timber products move smoothly from production to wrapping without manual intervention.

For companies with high-volume production lines, this integration can lead to significant improvements in productivity and efficiency. By customizing the wrapper to work with your material handling systems, you eliminate bottlenecks and ensure a seamless flow of products through the packaging process.

6. Customizable Speed and Automation Controls

The speed at which a horizontal orbital wrapper operates is a crucial factor in determining how efficiently your timber products are wrapped. Customizable speed controls allow you to set the machine’s wrapping pace based on the size and type of the product, ensuring optimal coverage without wasting time.

Many modern horizontal orbital wrappers also come with automation features that can be tailored to your specific packaging needs. For instance, an automated start-stop system can be integrated to control the flow of products in and out of the machine, reducing the need for manual handling. This type of automation not only improves operational efficiency but also enhances workplace safety by minimizing the risk of accidents during the wrapping process.

7. Enhanced Safety Features for Timber Handling

When dealing with large or heavy wooden products, safety becomes a top priority. Customizing a horizontal orbital wrapper with enhanced safety features can help protect both workers and the products themselves. Features such as emergency stop buttons, safety barriers, and load sensors can be integrated into the machine to prevent accidents and ensure the secure handling of timber products.

Additionally, some machines offer automated product centering systems, which align the product in the correct position before wrapping begins. This feature reduces the risk of misalignment, which can lead to damaged goods or machine malfunctions.

8. Custom Wrapping Patterns for Timber Protection

Not all timber products require the same level of protection, which is why customizable wrapping patterns are a valuable feature for businesses. Horizontal orbital wrappers can be programmed to apply different wrapping patterns based on the product’s fragility, size, and shape.

For instance, cross-wrapping can provide extra protection for fragile wooden products by securing them with multiple layers of stretch film in a criss-cross pattern. In contrast, spiral wrapping may be more suitable for larger, sturdier items like wooden beams, offering sufficient protection while using less film.

This flexibility in wrapping patterns allows businesses to optimize their packaging materials, ensuring that each product receives the appropriate level of protection without wasting film.

9. Remote Monitoring and Diagnostics

As with any automated machinery, downtime can be costly. Customizing your horizontal orbital wrapper with remote monitoring and diagnostics tools can help minimize this downtime by allowing operators to monitor the machine’s performance in real-time. These tools can alert operators to potential issues such as film jams, motor malfunctions, or sensor misalignments before they cause significant delays in production.

By addressing problems early, businesses can reduce the risk of costly repairs and extend the lifespan of the machine. Remote monitoring also allows for predictive maintenance, where the machine’s wear and tear can be tracked, enabling timely maintenance that prevents unexpected breakdowns.

10. Environmental Considerations: Sustainable Packaging Solutions

In today’s business environment, sustainability is more important than ever. Customizable features that focus on eco-friendly packaging solutions can help businesses meet their environmental goals. Horizontal orbital wrappers can be equipped with features that minimize film waste, use recyclable materials, or reduce energy consumption.

For example, machines can be customized to apply only the necessary amount of film, ensuring that packaging waste is kept to a minimum. Additionally, some machines come with energy-saving modes that reduce power consumption when the machine is not in use, further contributing to a sustainable packaging process.

By integrating these eco-friendly features, businesses can reduce their carbon footprint while still maintaining the efficiency and effectiveness of their timber packaging operations.

Conclusion: Maximizing Efficiency with Customized Horizontal Orbital Wrappers

For businesses in the timber and wood industries, investing in a customizable horizontal orbital wrapper is essential for improving packaging efficiency, protecting products, and reducing operational costs. The ability to tailor the machine to your specific needs—whether it’s adjusting the machine size, integrating with material handling systems, or adding custom safety features—ensures that your packaging process is as streamlined and effective as possible.

By taking advantage of the customizable features available in horizontal orbital wrappers, companies can optimize their timber packing processes, increase productivity, and ensure their products are safely protected during transportation and storage. As packaging requirements continue to evolve, investing in a customizable machine that can grow with your business will prove to be a smart, long-term decision.