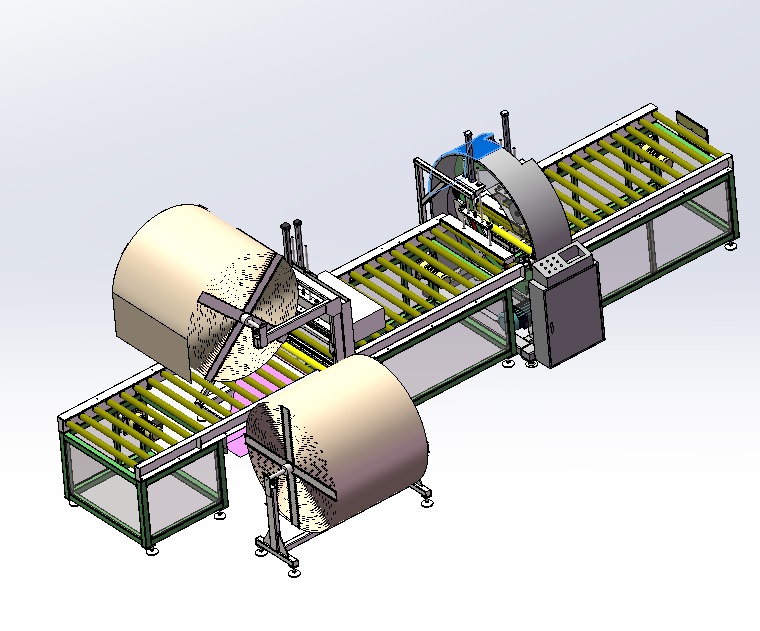

Improvement in the Bubble Film Spiral orbital wrapper:

1. Change the outer diameter of the bubble film with OD UPto 1200mm.

2. Adding the sensor to detecting the gap problems which needs the signal density 10mm.

3. Change the inner diameter of the winding film to 50 mm.

4. The sealing cutter head with clamping plate by 15mm for full cutting the bubble film.

5. The feeding direction of winding film roll adjust to the direction of the discharge conveyor line.

6. Docking with the front-line program to realize automatic package feeding and discharging.

7. Solve the problem that the film that is easy clipped in when the cutter is reset.

8. The shortest package is 400 mm.

9. Making the adjustment range allowance of the installation mechanism larger.

10. Adjust the beam on the bottom of the cutter cylinder, and move it to a position where the cutter cylinder does not interfere with each other.

11. Adjust the feeding position of the next rolled film, and consider placing it on the counter side.

12. Consider teflon treatment on the cutter splint.

13.Providing more information about stretch film coil setting.

14 Makes machine capable in realizing the packaging of single-layer and single-chip products.

15. Cancel or reduce the spring pressure because it is easy to flatten the bubble film.

16.Considering the outer diameter of the film roll of 220-250 mm.

17.Automatically identifying the lengths of products with different lengths.

18.When packaging small products, design the press down device for fixing bubble film.

19.Consider SCJ in pressing down cylinders

20. The heaviest object is 55kg. Consider PVC belt conveyor. The lightest object weight is 4.8Kg

.jpg)