How We Help You Make the Best Decision When Choosing a Coil Wrapping Machine?

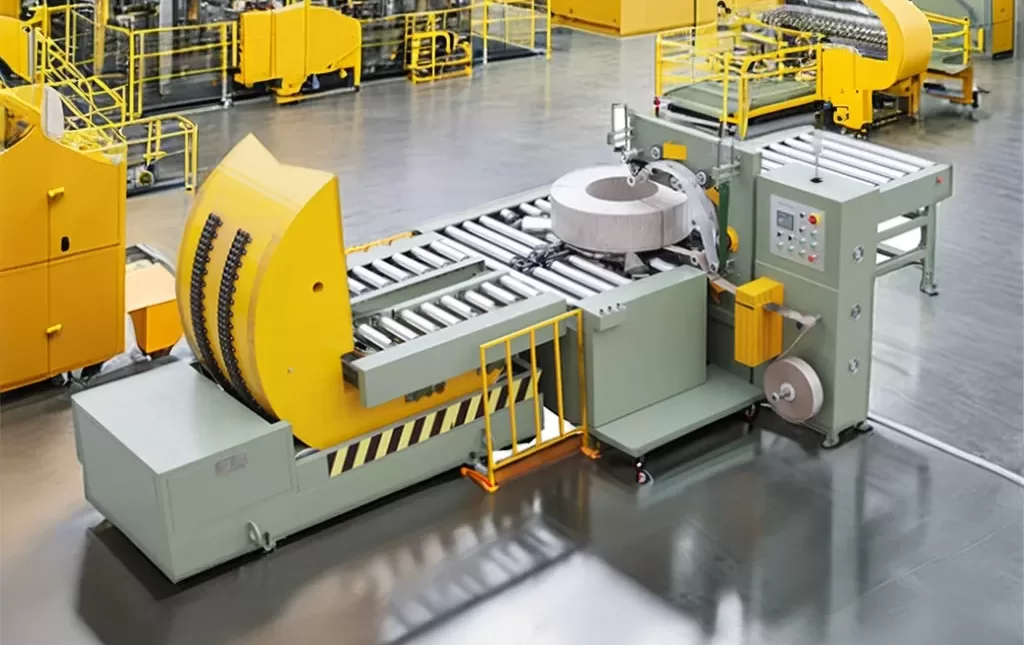

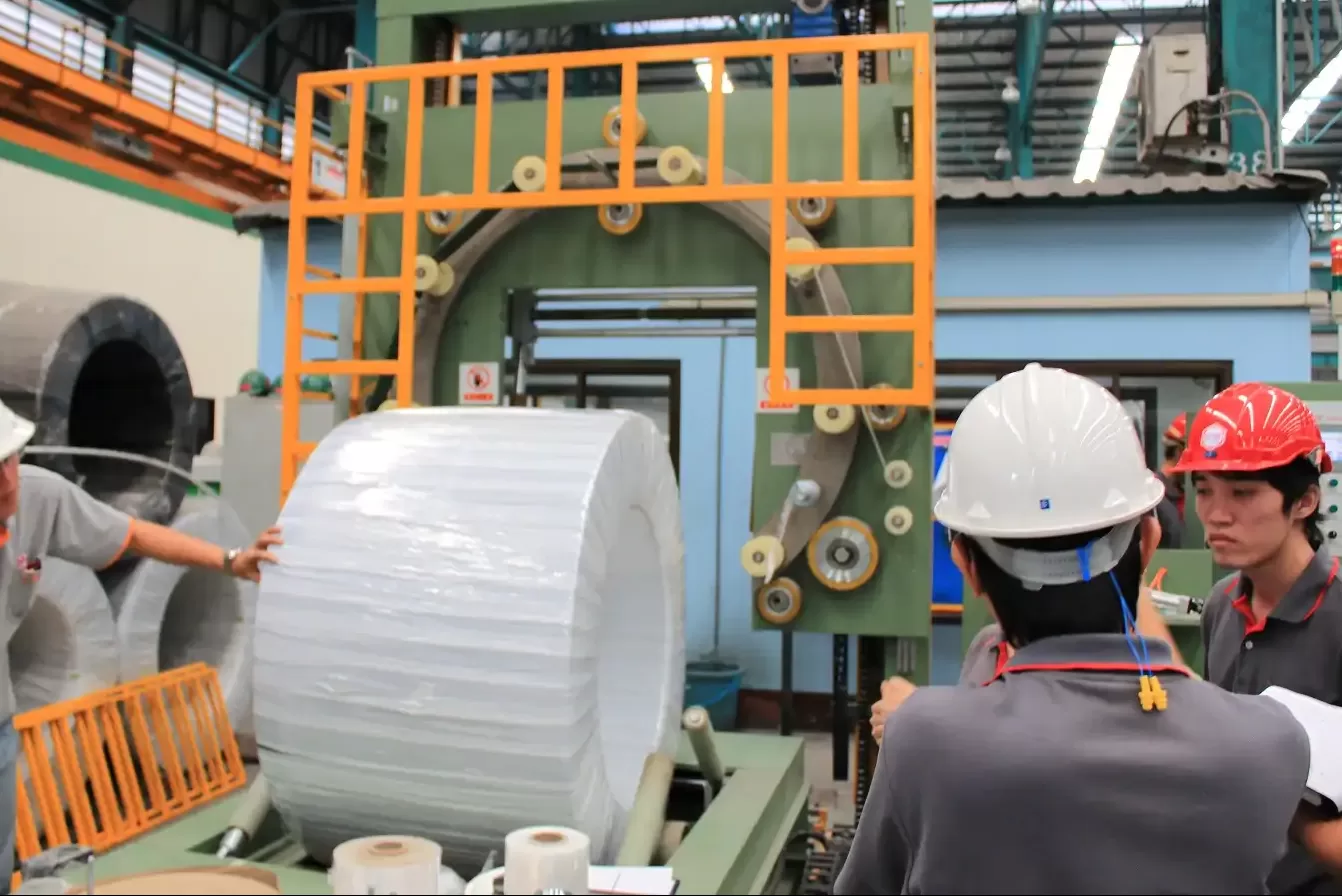

Your search for the perfect coil wrapping machine can feel overwhelming, with countless options, technical jargon, and varying price points to navigate. I’ve been in your shoes—trying to find the right balance between cost, reliability, and efficiency. You’re not just looking for a machine; you’re looking for a solution that improves your operations, protects your products, and gives you confidence in your investment. That’s exactly where we come in.

We understand that every customer has unique needs. From industries handling massive steel coils to those dealing with more delicate materials, our coil wrapping machines are designed to meet your specific production requirements. Today, I’ll guide you through how we ensure you make the best decision—one that fits your budget, aligns with your goals, and exceeds your expectations.

When you consider factors like durability, ease of operation, safety, and long-term ROI, you’ll see why our machines consistently stand out. Let’s explore how we address your concerns and deliver solutions that seamlessly integrate into your workflow.

1. What key features of our coil wrapping machine meet your production needs perfectly?

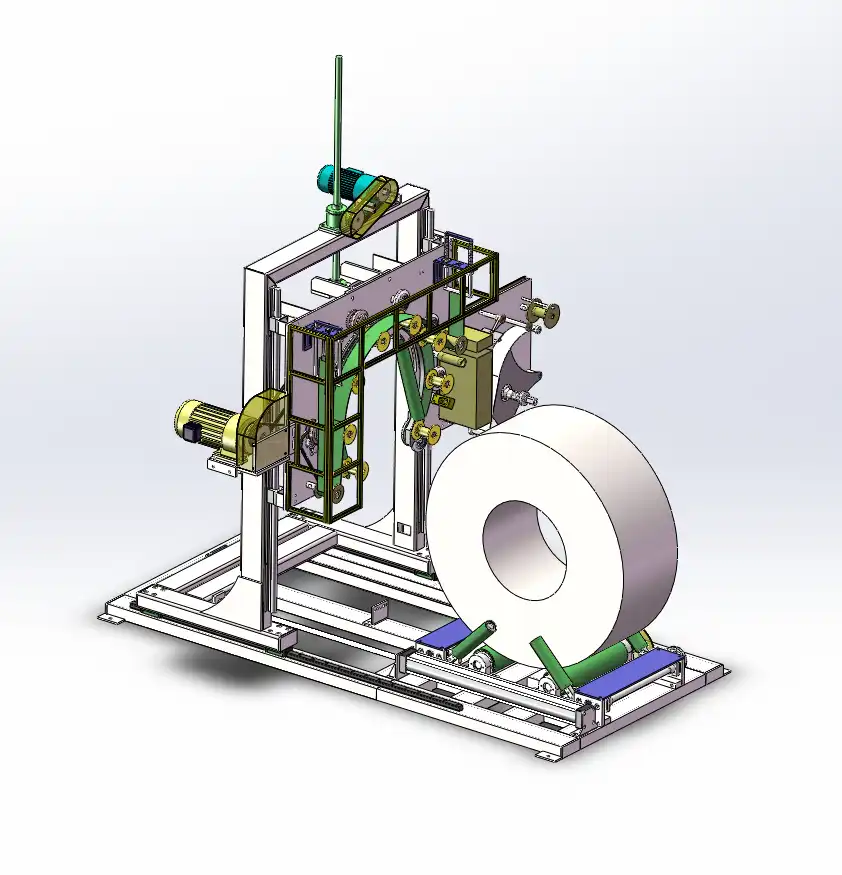

1.1 Why is precision engineering critical for your coil wrapping machine?

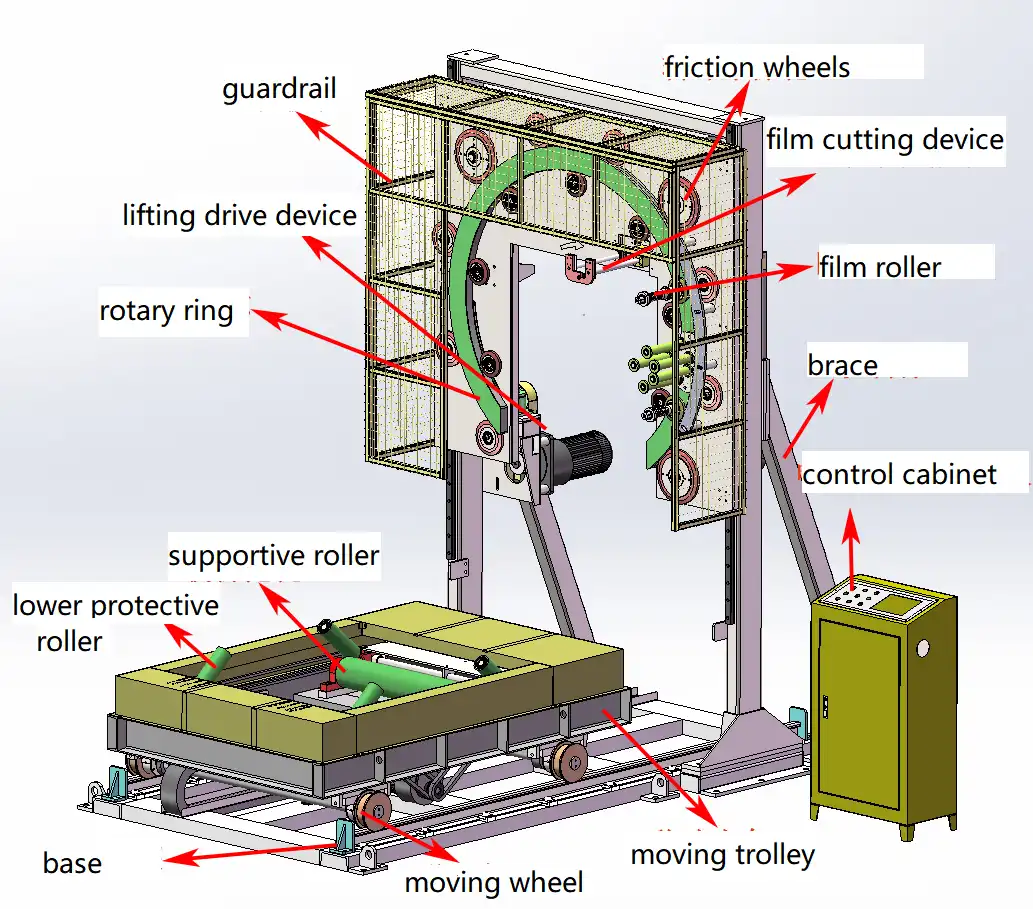

Every manufacturing process demands precision, and coil wrapping is no exception. When I first encountered the challenge of wrapping heavy-duty steel coils, I quickly realized that even the smallest miscalculation in a machine's design could lead to damaged products or inefficient processes. That’s why our coil wrapping machines are engineered with accuracy in mind.

Our machines achieve this through:

- Adjustable wrapping settings for different coil sizes: Whether you’re working with 500mm or 2000mm diameter coils, our machines adapt seamlessly.

- Smooth tension control: Ensures that the wrapping material clings perfectly to the coil without tearing or slipping.

- High-speed automated operation: Reduces downtime and increases output.

For instance, one of our customers recently upgraded to our automated horizontal coil wrapping machine and saw a 30% improvement in production efficiency, saving over $20,000 annually on labor costs.

1.2 What technical specifications matter most?

Choosing the right coil wrapping machine requires understanding its capabilities and compatibility with your products. Below is a comparison of key technical specifications across our product range:

| Feature | Semi-Automated Machine | Fully Automated Machine |

|---|---|---|

| Wrapping Speed | 25-40 coils/hour | 50-70 coils/hour |

| Material Compatibility | PE film, stretch film, paper | Multi-layer advanced films |

| Coil Diameter Range | 500-2000mm | Customizable up to 2500mm |

| Power Supply | 220V/380V, 50/60Hz | 380V, 50Hz (customizable) |

| Operator Requirement | 1-2 people | Minimal supervision |

With options to suit small-scale operations and high-capacity industrial lines, our machines are built to meet the demands of various industries—steel, aluminum, cable, and beyond.

1.3 How does automation improve your workflow?

Automation isn’t just a luxury; it’s a necessity for modern manufacturing. Our coil wrapping machines integrate cutting-edge automation features to ensure consistency, reduce human error, and maximize throughput.

Key automation features include:

- PLC-controlled operation: Allows for pre-programmed wrapping patterns and materials.

- Automatic film cutting and starting: Eliminates the need for manual intervention, saving time and effort.

- Sensor-based coil detection: Ensures perfect alignment and wrapping every time.

One of our clients in the steel industry reported that switching to our automated machine reduced errors by 95% and boosted overall production capacity by 20%.

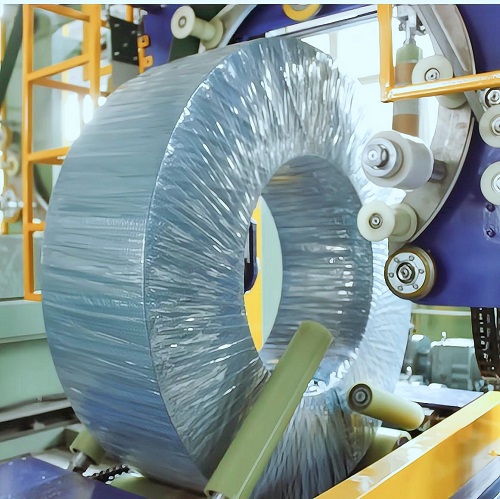

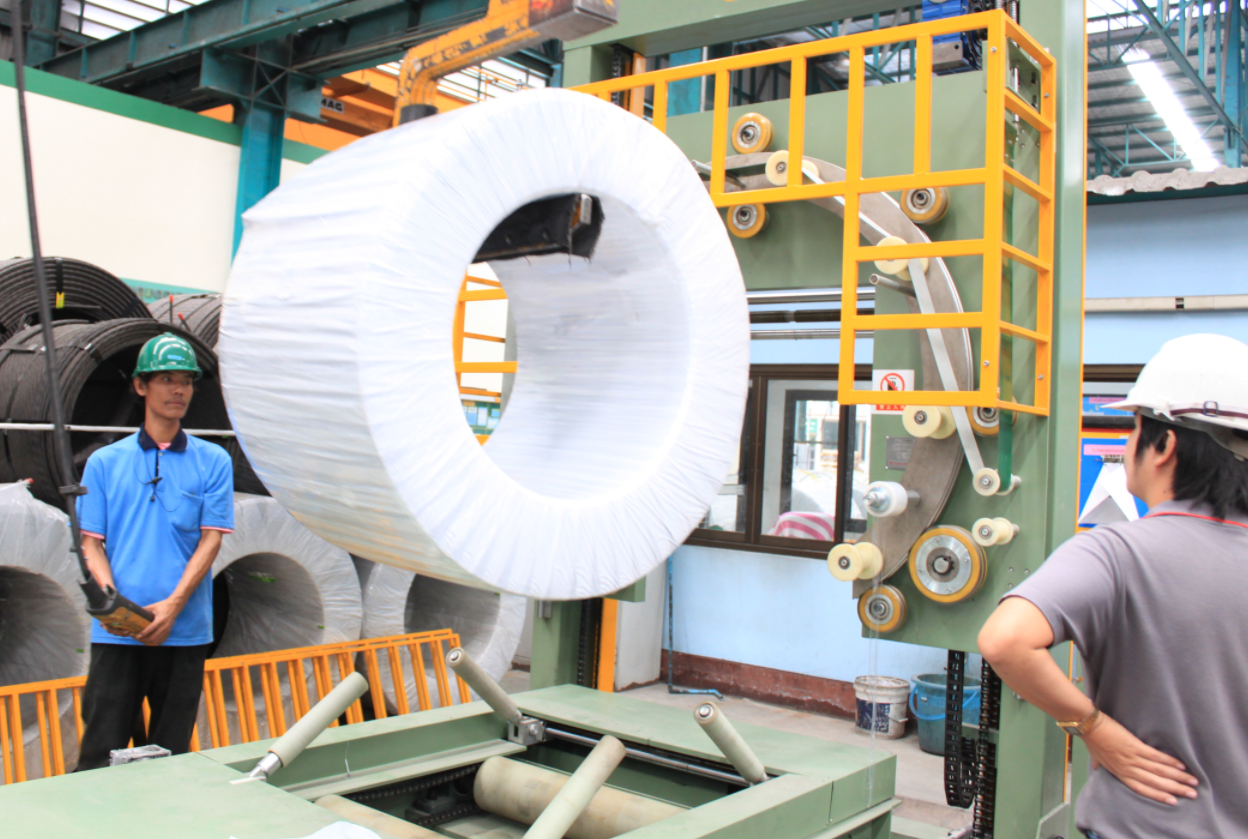

1.4 How do our machines protect your products?

The last thing you want is for your coils to be damaged during transit or storage due to poor wrapping. Our machines are designed to provide complete protection with features like:

- Edge protection systems: Prevents damage to the edges of the coils.

- Tight wrapping with no slack: Keeps coils secure during transport.

- Moisture-resistant wrapping materials: Safeguards against rust and corrosion.

For example, a customer shipping coils overseas reported zero product damage after implementing one of our machines with advanced moisture-resistant wrapping.

1.5 Comparing key solutions for your wrapping needs

To help you evaluate which solution best fits your operations, here’s a quick comparison of our offerings:

| Machine Type | Best For | Advantages | Price Range |

|---|---|---|---|

| Semi-Automated | Small to medium operations | Cost-effective, easy to operate | $8,000-$15,000 |

| Fully Automated | High-volume industrial lines | High speed, minimal operator involvement | $20,000-$35,000 |

| Custom Machines | Unique production needs | Tailored to specific requirements | $25,000+ |

This breakdown highlights how we provide tailored solutions, ensuring you get the best return on your investment.

2. How does our experience and industry reputation ensure a reliable partnership?

2.1 Why does industry expertise matter when choosing a coil wrapping machine manufacturer?

When investing in a machine that will integrate into your production line, experience isn't just an added bonus—it’s a necessity. A reliable coil wrapping machine manufacturer understands the nuanced challenges of your industry, from production bottlenecks to product protection during transportation.

With over 15 years of industry expertise, we’ve worked with clients across diverse sectors, including steel, aluminum, and cable manufacturing. This wealth of experience allows us to anticipate potential issues and provide solutions that ensure seamless operations.

For example, one of our clients in the steel industry faced frequent downtime due to subpar wrapping equipment from a competitor. After switching to our machines, they reported a 30% reduction in downtime and a significant improvement in product protection.

2.2 What do customer reviews and industry recognition say about us?

Our dedication to quality and customer satisfaction has earned us a strong reputation in the industry. Here’s a quick overview of how we’re perceived:

| Metric | Details |

|---|---|

| Customer Satisfaction | 95% of clients renew their contracts |

| Global Reach | Exported to over 50 countries worldwide |

| Industry Certifications | ISO 9001, CE certification, RoHS compliance |

| Awards | “Top Machinery Innovator” (Industry Leader Award 2023) |

Customer Testimonial:

"Before working with them, we struggled with subpar machines that couldn’t handle the weight of our steel coils. Their coil wrapping machine not only met but exceeded our expectations. We’ve since standardized all wrapping operations with their equipment." – John T., Steel Manufacturer

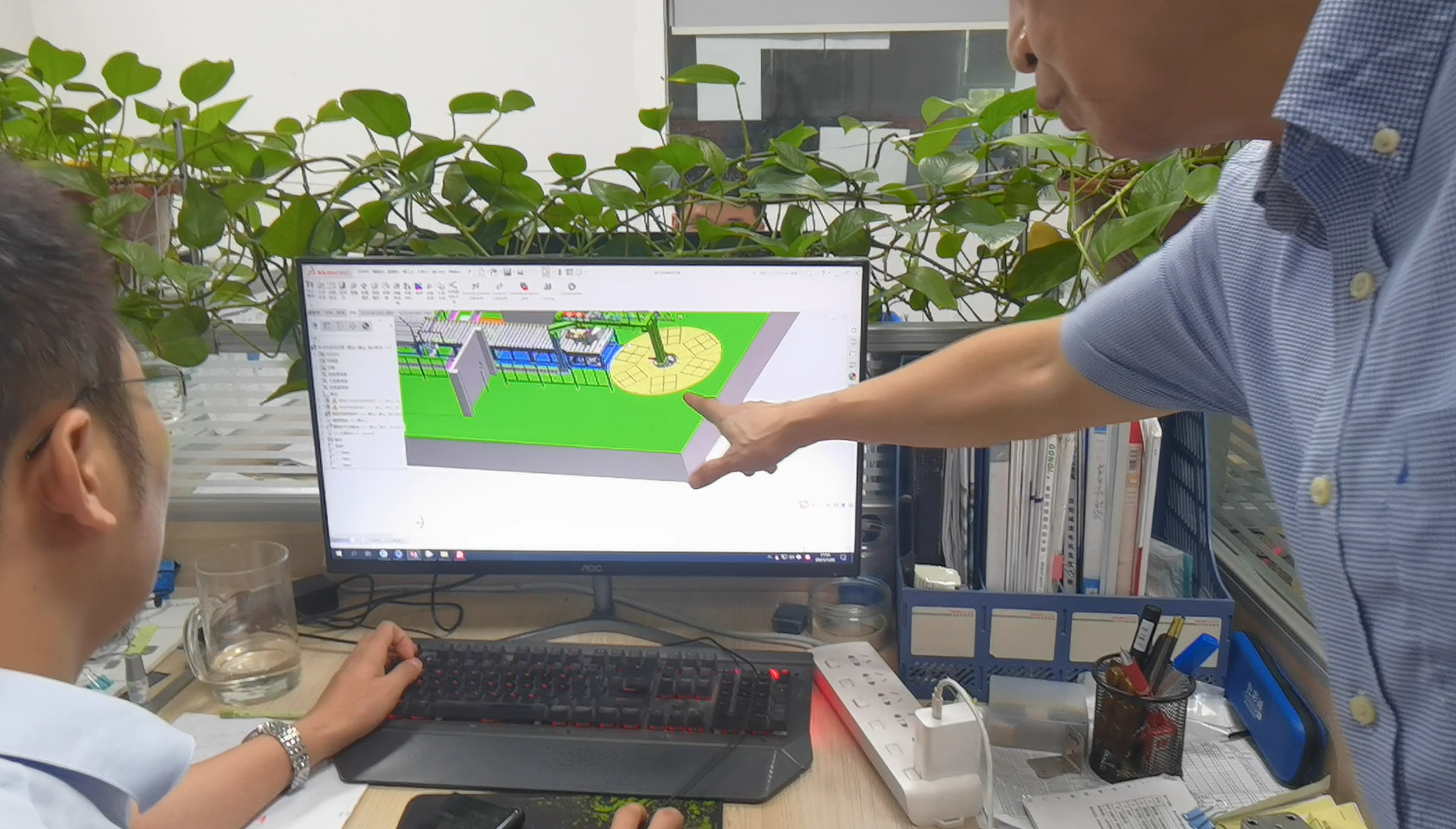

2.3 How do we support you throughout the decision-making process?

When purchasing a coil wrapping machine, you’re not just buying a product—you’re entering a partnership. Our team supports you at every stage:

- Pre-sales consultation: We carefully assess your production needs and recommend the best machine for your operations.

- Site visits and testing: For large-scale operations, we offer on-site evaluations and product demonstrations.

- Custom design solutions: If our standard machines don’t fit your needs, we’ll tailor one that does.

For instance, a cable manufacturer required a custom wrapping solution for irregularly shaped coils. We designed a machine with adjustable wrapping arms and programmable settings, which resulted in a 50% increase in wrapping efficiency.

3. What cost transparency can we provide to help you evaluate ROI confidently?

3.1 How do we break down the price of a coil wrapping machine?

Price transparency is critical when making a significant investment. We provide a detailed breakdown of costs so you know exactly where your money is going:

| Cost Component | Percentage of Total Cost | Details |

|---|---|---|

| Manufacturing | 60% | High-quality materials and precise engineering |

| Customization | 15% | Tailored features to meet unique needs |

| Shipping and Logistics | 10% | Safe delivery, including heavy-duty packaging |

| Installation and Training | 10% | On-site setup and operator training |

| After-Sales Support | 5% | Maintenance, troubleshooting, and spare parts |

This level of transparency allows you to evaluate the true value of your investment and compare it with competitors.

3.2 How do we calculate ROI for your investment?

To help you make an informed decision, we provide a detailed ROI analysis. Here’s an example of how our machines deliver measurable benefits:

| Metric | Before Our Machine | After Our Machine | Improvement |

|---|---|---|---|

| Downtime (hours/month) | 20 | 5 | 75% reduction |

| Labor Costs ($/month) | 10,000 | 6,500 | 35% savings |

| Coil Damage Incidents | 8 | 1 | 88% fewer incidents |

| Wrapping Time (minutes/coil) | 6 | 3 | 50% faster wrapping |

In this scenario, the customer recouped their investment in less than 12 months, thanks to the combined savings in labor, downtime, and reduced product damage.

3.3 What pricing models do we offer?

We understand that companies have different financial needs. That’s why we offer flexible pricing options:

- Outright Purchase: Ideal for companies with strong cash flow, giving you full ownership.

- Leasing Options: Spread the cost over time to align with your budget.

- Pay-As-You-Grow Plans: For smaller businesses or startups, this model scales costs with your production volume.

For example, one of our clients, a mid-sized aluminum coil manufacturer, opted for a leasing plan. They reported that the minimal upfront cost allowed them to invest in other production upgrades simultaneously.

3.4 Comparing our pricing transparency with competitors

It’s easy to be swayed by low upfront prices, but hidden fees can quickly turn a bargain into a burden. Here’s how we stack up against competitors:

| Aspect | Our Coil Wrapping Machine | Competitor A | Competitor B |

|---|---|---|---|

| Upfront Cost | Transparent, itemized | Lower upfront cost | Mid-range upfront cost |

| Hidden Fees | None | Yes (installation, training) | Yes (after-sales support) |

| Customization Options | Fully flexible | Limited | Moderate |

| After-Sales Support | Included in price | Extra charges | Limited warranty only |

By taking a long-term view of cost-efficiency, you’ll see that our machines provide the best value for your investment.

4. How does our comprehensive after-sales service keep your operations running smoothly?

4.1 Why is after-sales service critical for your investment?

Purchasing a coil wrapping machine is just the beginning of your journey. To ensure your investment continues delivering value, comprehensive after-sales support is essential. Machines, no matter how advanced, require maintenance, troubleshooting, and occasional upgrades to perform at their best.

Our after-sales service is designed to minimize downtime, reduce operational headaches, and extend the lifespan of your machine. Imagine having a team that’s ready to assist you at a moment’s notice, whether it’s a quick online troubleshooting session or an on-site repair by our certified technicians.

For instance, one of our steel industry clients faced unexpected downtime due to an operator error. Within 48 hours, our team provided a remote diagnosis, sent replacement parts, and walked their team through the repair process, saving them thousands of dollars in lost productivity.

4.2 What services do we include in our after-sales package?

We believe in providing holistic support that covers every aspect of your machine’s lifecycle. Here’s what you can expect:

| Service | Details |

|---|---|

| Installation Manual | Comes with a step-by-step guide for setup. |

| Online Troubleshooting | 24/7 remote support with real-time diagnosis. |

| On-Site Commissioning | Expert technicians ensure proper installation and calibration. |

| Distributor Local Service | Regional support for faster response times. |

| Preventative Maintenance | Regular health checks to prevent breakdowns. |

This comprehensive approach ensures that your machine runs smoothly, with minimal interruptions.

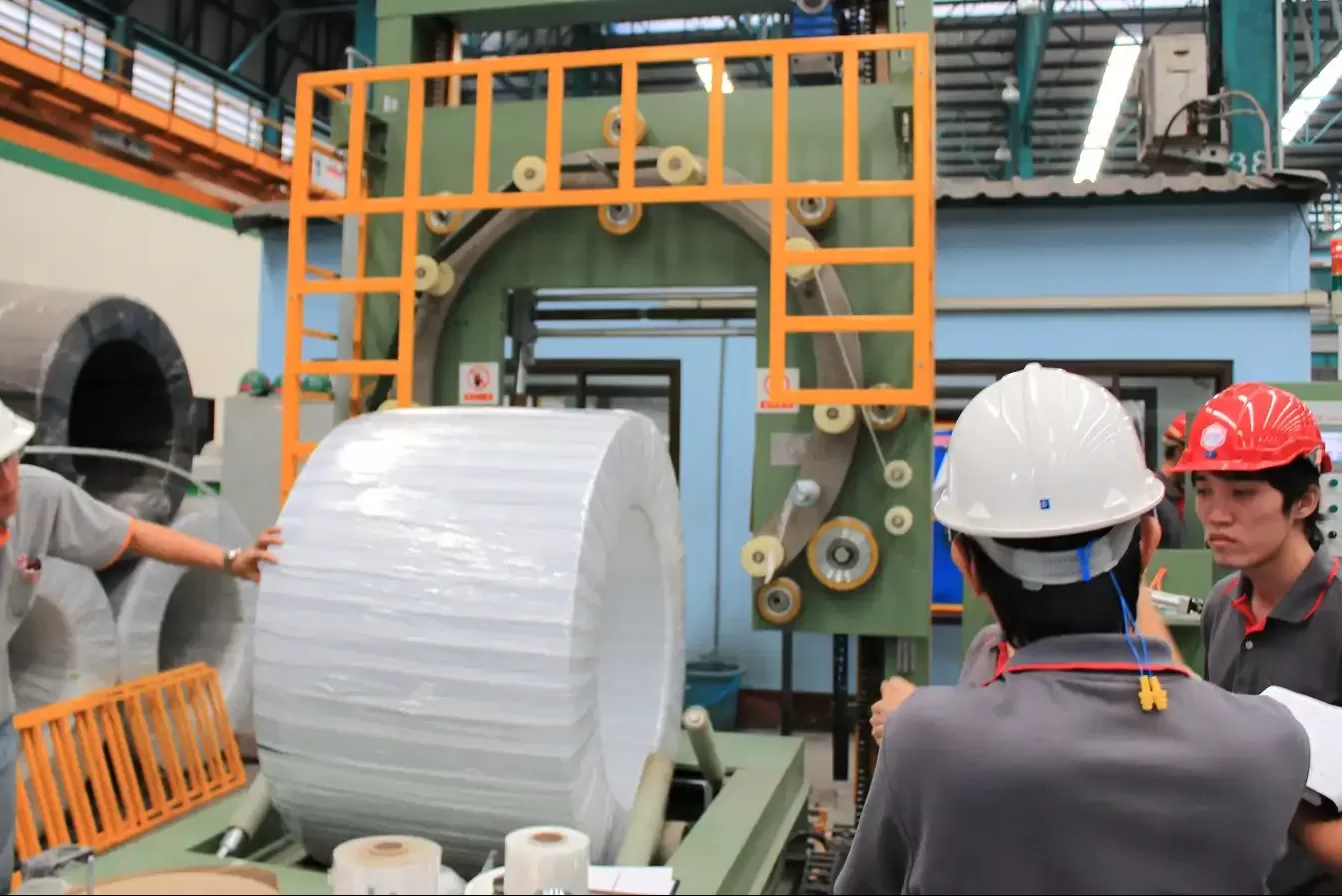

4.3 How do we handle on-site commissioning?

On-site commissioning is a game-changer for businesses that want to ensure optimal machine performance from day one. Our team of skilled technicians arrives at your location, handles the setup, tests the equipment, and trains your staff.

Steps we follow during on-site commissioning:

- Inspection: Verify the machine’s condition after transportation.

- Installation: Assemble components and connect the machine to power and air supplies.

- Calibration: Configure wrapping settings to match your production requirements.

- Testing: Perform test runs to ensure smooth operation.

- Training: Provide hands-on operator training to ensure your team is confident in using the machine.

One client noted that our on-site commissioning service saved them two weeks of trial-and-error setup time, allowing them to meet their production deadlines.】

4.4 How do we ensure fast issue resolution?

Downtime can be costly, so we’ve built a robust support system to resolve issues as quickly as possible.

| Support Channel | Response Time | Details |

|---|---|---|

| 24/7 Online Troubleshooting | Immediate | Remote diagnostics and guidance via video calls. |

| Spare Parts Availability | 48 hours (domestic), 72 hours (international) | Maintain stock of critical components. |

| Local Distributor Service | Same day | Certified technicians in your region for faster repairs. |

This layered approach ensures that no matter where you are, help is always within reach.

5. Why is our semiauto pallet wrapping machine designed to exceed safety and compliance standards?

5.1 How do we prioritize safety in our designs?

Safety isn’t just a legal requirement—it’s a fundamental responsibility. When handling heavy loads, such as pallets or coils, even a minor safety oversight can lead to accidents, injuries, or costly damage. That’s why our semiauto pallet wrapping machines are designed with layered safety features to protect operators and ensure compliance with global safety standards.

For example, our machines are built to handle up to 20% overload capacity, ensuring they remain stable and safe even in high-stress scenarios. Additionally, we incorporate safety sensors that immediately halt operations if an obstruction is detected, preventing accidents before they happen.

5.2 What advanced safety features are included in our machines?

| Safety Feature | Purpose |

|---|---|

| Overloading Design (20%) | Provides extra durability and stability beyond rated capacity. |

| Protective Fencing | Prevents unauthorized access to the machine’s working area. |

| Light Beam Sensors | Detects obstructions and halts operations instantly. |

| Emergency Stop Buttons | Allows operators to stop the machine immediately in case of danger. |

| Low Noise Operation | Reduces noise pollution, creating a safer work environment. |

These features are not just about meeting compliance—they’re about creating a workspace where your team feels secure.

5.3 How do we ensure regulatory compliance?

Our machines meet or exceed safety standards in every region we operate, giving you peace of mind that your investment is fully compliant.

| Standard | Requirement | Our Compliance |

|---|---|---|

| CE Certification (Europe) | Machinery safety and operational compliance | Fully certified for European markets. |

| ISO 12100:2010 | General principles for machinery safety | Comprehensive risk assessment and testing. |

| OSHA Standards (USA) | Workplace safety measures | Integrated safety features for compliance. |

This commitment ensures that your operations remain safe, efficient, and aligned with all legal requirements.

5.4 How do our safety features compare to competitors?

To help you see the difference, here’s a comparison of our semiauto pallet wrapping machines with those of leading competitors:

| Feature | Our Machine | Competitor A | Competitor B |

|---|---|---|---|

| Overloading Capacity | 20% | 10% | Not disclosed |

| Protective Fencing | Standard | Optional | Not included |

| Light Beam Sensors | Included | Optional | Not included |

| Noise Level | <70 dB | >80 dB | Not disclosed |

| Compliance | CE, ISO, OSHA | CE only | Limited |

By exceeding industry standards, our machines not only protect your workforce but also reduce the risk of costly legal issues.

6. What training and technical support do we offer to ensure seamless integration?

6.1 Why is training critical for seamless machine integration?

Purchasing a coil wrapping machine is only the first step. To ensure it delivers maximum efficiency and supports your production goals, your team needs proper training. Without it, even the most advanced machinery can become a bottleneck in your workflow. Our training programs are designed to eliminate confusion, increase operator confidence, and ensure smooth integration into your existing processes.

We’ve seen firsthand how training transforms operations. One of our clients, a mid-sized cable manufacturer, reported a 40% reduction in operator errors after completing our comprehensive training program. This improvement not only boosted their productivity but also minimized material waste.

6.2 What technical support do we provide to minimize downtime?

Our technical support services are tailored to address both immediate issues and long-term maintenance needs. Here’s an overview of what we offer:

| Support Service | Details | Benefits |

|---|---|---|

| On-Site Training | Hands-on operator training during installation | Ensures your team can operate the machine confidently. |

| Video Tutorials | Step-by-step guides covering common operations | Provides quick, accessible solutions. |

| Online Support | Remote troubleshooting via video calls | Reduces downtime by resolving issues quickly. |

| Upgraded Manuals | Comprehensive, easy-to-follow documentation | Simplifies machine setup and maintenance. |

This multi-channel approach ensures that you have access to the resources you need, whenever you need them.

6.3 How do we tailor training to your specific needs?

No two operations are the same, which is why we customize our training programs to match your unique requirements.

For instance, if your facility uses forklifts for loading, we provide specific guidance on integrating that workflow with the machine. For customers using conveyors or hand jacks, we adapt our training to optimize those systems.

Training modules include:

- Basic operations: Understanding machine components and controls.

- Safety protocols: Ensuring compliance with workplace safety standards.

- Troubleshooting: Identifying and resolving common issues.

- Efficiency tips: Optimizing settings for faster and more consistent wrapping.

This level of customization ensures your team is fully equipped to maximize the machine’s potential.

6.4 How does our technical support reduce long-term costs?

Effective technical support isn’t just about fixing problems—it’s about preventing them. By providing proactive maintenance tips and real-time assistance, we help you avoid costly downtime and repairs.

| Key Metric | Without Our Support | With Our Support | Improvement |

|---|---|---|---|

| Downtime (hours/month) | 15 | 5 | 67% reduction |

| Maintenance Costs ($/year) | $8,000 | $4,000 | 50% savings |

| Operator Errors | 10/month | 2/month | 80% fewer errors |

Our goal is to ensure your machine operates at peak performance for years to come, delivering exceptional ROI.

7. How do we customize semiauto pallet wrapping machines to maximize efficiency?

7.1 Why is customization important for your operations?

Every production facility is different, with unique challenges and requirements. A one-size-fits-all machine may work, but it’s unlikely to deliver optimal results. That’s why we focus on customization—designing semiauto pallet wrapping machines that align perfectly with your workflow, product types, and operational goals.

For example, a client in the food packaging industry required a machine that could handle both vertical and horizontal wrapping for various pallet sizes. By customizing their machine with adjustable wrapping arms and programmable settings, we helped them achieve a 25% boost in daily output.

7.2 What customization options do we offer?

Our machines are designed to adapt to your specific needs, offering a wide range of customization options:

| Customization Feature | Details | Benefits |

|---|---|---|

| Loading Methods | Compatible with forklifts, conveyors, or hand jacks | Flexibility to match your existing equipment. |

| Wrapping Station Type | Movable, fixed, horizontal, or vertical | Tailored to your space and product types. |

| Motor and PLC Upgrades | High-efficiency motors, advanced PLC systems | Faster, more reliable operation. |

| Brand Components | Options for Siemens, Schneider, or ABB parts | Enhances durability and performance. |

| Film Stretch Ratio | Adjustable settings for different materials | Reduces material waste and costs. |

This flexibility ensures that your machine integrates seamlessly into your workflow, maximizing efficiency and minimizing disruptions.

7.3 How do we optimize wrapping for different pallet types?

Pallets come in all shapes and sizes, and our machines are designed to handle them all. Whether you’re wrapping standard pallets, oversized loads, or irregular shapes, we provide solutions that ensure stability and protection.

Key features for pallet optimization include:

- Adjustable wrapping arms: Accommodate pallets of different heights and widths.

- Pre-stretch film technology: Ensures even wrapping for irregularly shaped loads.

- High-speed rotation: Reduces wrapping time without compromising quality.

One of our clients, who ships fragile electronic equipment, reported a 90% reduction in product damage after upgrading to our customized wrapping machine with advanced tension control.

7.4 Comparing customization solutions for various industries

To help you understand how customization impacts efficiency, here’s a comparison of solutions for different industries:

| Industry | Customization Required | Our Solution | Outcome |

|---|---|---|---|

| Steel Manufacturing | Heavy-duty wrapping for large coils | Horizontal wrapping machine with edge protection | 30% faster wrapping, zero product damage |

| Food Packaging | Flexible wrapping for various pallet sizes | Movable station with programmable settings | 25% increase in output |

| Electronics | Delicate product protection | Precision tension control and pre-stretch film | 90% fewer damages during transit |

By tailoring our machines to meet your industry’s specific demands, we ensure you achieve the best possible results.

8. What makes our delivery timelines and installation process stress-free and efficient?

8.1 How do we simplify the delivery and installation process?

Delivery and installation can often be the most stressful part of purchasing a coil wrapping machine. Long timelines, confusing installation procedures, and unexpected delays can disrupt your operations. That’s why we’ve streamlined our process to ensure fast delivery and hassle-free installation, saving you time and effort.

Our machines are designed with a “plug-and-play” philosophy—requiring minimal setup. Once the machine arrives, all you need to do is unpack, connect the power and air supply, and follow our easy-to-use installation guide. For customers who prefer additional support, we provide remote assistance or on-site installation services.

One of our clients, a mid-sized manufacturer, praised our simplified process:

"We were up and running in less than two hours after delivery. The video guide made the setup process incredibly straightforward."

8.2 What tools and resources do we provide for installation?

We equip you with everything you need to get your machine operational quickly and efficiently:

| Resource | Details |

|---|---|

| Installation Manual | Step-by-step guide with diagrams and instructions. |

| Video Tutorials | Detailed walkthroughs for unpacking and setup. |

| Remote Support | Real-time assistance via video calls, if needed. |

| On-Site Installation | Expert technicians handle the setup for you. |

Additionally, our machines come pre-assembled to the greatest extent possible, reducing the need for complex mechanical work during installation.

8.3 How do we minimize delays in delivery?

Timely delivery is a priority for us. We work closely with reliable logistics partners to ensure your machine reaches you without delays. Here’s how we achieve that:

- Optimized Packaging: Machines are securely packed to prevent damage during transit.

- Pre-shipment Testing: Every machine is tested before shipping to avoid issues upon arrival.

- Real-Time Tracking: You’ll receive updates on your shipment’s status at every stage.

For example, one of our international clients in South America received their machine within 10 days, significantly faster than the industry average of 15-20 days.

8.4 Comparison of our delivery and installation process with competitors

| Aspect | Our Process | Competitor A | Competitor B |

|---|---|---|---|

| Delivery Time | 7-15 days (domestic), 15-20 days (international) | 15-20 days | 20-30 days |

| Installation Requirements | Plug-and-play, simple setup | Complex assembly required | Partial pre-assembly |

| Support Options | Manual, video guide, remote & on-site support | Manual only | Manual & limited support |

| Pre-shipment Testing | Standard for all machines | Limited | Limited |

Our streamlined delivery and installation process ensures your operations are disrupted as little as possible, and you can start using your machine quickly.

9. How can our success stories and case studies build trust in our solutions?

9.1 Why are customer success stories important?

When it comes to investing in a coil wrapping machine, nothing speaks louder than real-world results. Success stories and case studies provide tangible proof of our machines’ performance, reliability, and value. They demonstrate how we’ve helped businesses like yours overcome challenges, improve efficiency, and reduce costs.

For example, a steel coil manufacturer faced frequent damage during transportation due to poor wrapping. After switching to our fully automated coil wrapping machine, they reported a 95% reduction in product damage, saving over $50,000 annually in claims and replacements.

9.2 What are some of our most notable case studies?

Here are three examples of how we’ve delivered results for our clients:

| Client | Challenge | Solution | Outcome |

|---|---|---|---|

| Steel Manufacturer | High product damage during transit | Horizontal coil wrapping machine with edge protectors | 95% reduction in damage, $50K savings |

| Cable Manufacturer | Low efficiency with manual wrapping | PLC-controlled automated wrapping machine | 40% increase in efficiency, reduced labor |

| Aluminum Coil Exporter | Corrosion issues due to inadequate wrapping | VCI film wrapping with moisture-resistant settings | Zero corrosion incidents in 12 months |

These case studies highlight how our machines consistently deliver measurable improvements in productivity, cost savings, and product protection.

9.3 How do we ensure transparency in our success stories?

We believe in full transparency when sharing our success stories. That means:

- Providing specific data on performance improvements, cost savings, and ROI.

- Including direct quotes and testimonials from our clients.

- Offering references so potential customers can verify our claims.

For instance, one client allowed us to publish a detailed report on how our machine improved their wrapping process, including before-and-after metrics and their testimonial. This openness reinforces trust and demonstrates our commitment to delivering real results.

9.4 Why do our success stories set us apart?

Unlike competitors who rely on generic claims, we provide detailed, verifiable case studies that showcase our commitment to quality and customer satisfaction. Here’s how we compare:

| Aspect | Our Approach | Competitor A | Competitor B |

|---|---|---|---|

| Case Study Detail | Metrics, testimonials, references | General claims | Limited details |

| Industry Coverage | Steel, aluminum, cable, etc. | Limited to one industry | Limited to one industry |

| Transparency | Full transparency | Limited insights | No verifiable data |

Our success stories aren’t just marketing—they’re proof of our ability to deliver solutions that exceed expectations.

10. What clear and flexible contract terms do we offer to protect your investment?

10.1 Why are transparent contract terms important?

Investing in a coil wrapping machine is a significant decision, and the last thing you want is to be surprised by hidden fees or unclear conditions. Transparent and flexible contract terms not only protect your investment but also build trust between you and the manufacturer. We prioritize clarity, ensuring you know exactly what you’re paying for and what to expect from our partnership.

Our contracts are designed to provide peace of mind. From warranty coverage to payment schedules, every detail is outlined in plain language—no fine print, no surprises. For example, one of our clients, a new entrant in the aluminum coil industry, appreciated our flexible payment options, which allowed them to get started with minimal upfront costs.

10.2 What key elements are included in our contracts?

We take pride in offering contracts that are both comprehensive and flexible, covering every aspect of your purchase. Our standard contracts include:

| Contract Element | Details |

|---|---|

| Warranty Terms | Covers parts and labor for 12-24 months, with optional extensions. |

| Payment Options | Full payment, leasing, or installment plans to suit your budget. |

| Delivery Guarantee | Ensures on-time delivery with penalties for delays. |

| After-Sales Support | Includes free troubleshooting, spare parts discounts, and maintenance. |

| Training Programs | Operator training included in the package, with an option for advanced sessions. |

This level of detail ensures that you’re fully protected while also enjoying the flexibility to customize terms based on your specific needs.

10.3 How do our contracts address potential risks?

We’ve built provisions into our contracts to safeguard your investment from unforeseen risks. These include:

- Damage During Shipping: In the rare event that your machine is damaged during transit, we cover the cost of repairs or replacements.

- Performance Guarantees: If the machine does not meet the agreed-upon specifications, we’ll make the necessary adjustments at no additional cost.

- Flexible Return Policy: If the machine fails to integrate into your operations due to technical incompatibility, you can return it within an agreed-upon period.

For instance, one of our clients in the cable industry needed to return a machine due to a shift in their production requirements. Thanks to our flexible return policy, they were able to upgrade to a more suitable model without incurring additional fees.

10.4 How do our contract terms compare to competitors?

Here’s a side-by-side comparison of how our contract terms stack up against industry standards:

| Aspect | Our Contract | Competitor A | Competitor B |

|---|---|---|---|

| Warranty Length | 12-24 months, extendable | 12 months | 6-12 months |

| Payment Options | Multiple flexible options | Full payment upfront | Limited flexibility |

| Delivery Guarantee | Included with penalties | Not guaranteed | Not guaranteed |

| Return Policy | Flexible for compatibility | No returns | Strict conditions apply |

| After-Sales Support | Comprehensive and included | Limited | Extra cost |

This commitment to transparency and flexibility places us ahead of the competition, ensuring your investment is secure and your expectations are met.

Conclusion

Making the right choice in a coil wrapping machine means considering every factor—performance, reliability, cost, and support. As a trusted coil wrapping machine manufacturer, we aim to simplify this process for you, ensuring not only that you get the best machine for your needs but also that your investment is protected at every stage.

Our machines stand out because they are designed to meet the unique challenges of your operations, whether it’s protecting delicate aluminum coils from corrosion or ensuring heavy steel coils are wrapped efficiently for transport. But we don’t stop there. From our industry-leading after-sales support to our transparent contract terms, we aim to build a partnership that you can rely on for years to come.

When you choose us, you’re not just buying a machine—you’re investing in a solution tailored to increase efficiency, reduce costs, and drive your business forward. Our clients’ success stories speak for themselves, and we’re ready to help you become the next one.

Are you ready to make the best decision for your production needs? Let’s start this journey together.