What to Look for in a High-Performance Coil Wrapping Machine for Steel Strip

Introduction

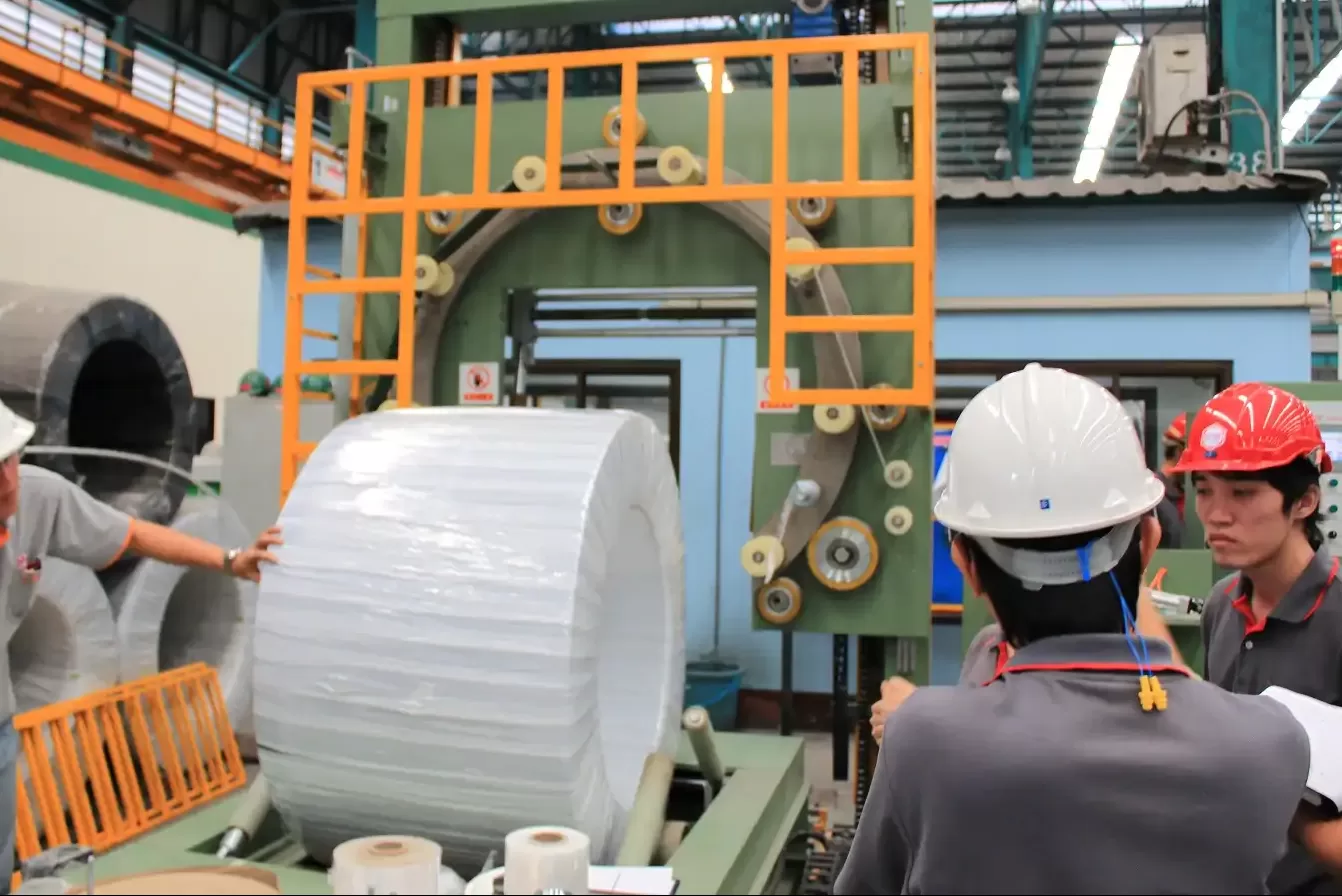

In industries that manufacture, store, and transport steel strips, efficient coil wrapping is vital for protecting the product against damage and corrosion. Investing in a high-performance coil wrapping machine can dramatically improve both the speed and quality of packaging processes, ensuring steel coils arrive in perfect condition. But with so many options on the market, how do you choose the right one? This guide covers all the essential features to look for in a high-performance coil wrapping machine, helping you make a decision that benefits your production line and bottom line.

Understanding Coil Wrapping Machines for Steel Strips

A coil wrapping machine is a specialized piece of equipment designed to wrap steel coils with protective materials, such as stretch film, VCI (Volatile Corrosion Inhibitor) paper, or other coverings, to prevent surface damage, corrosion, and contamination. These machines vary in design, with options for fully automated systems that streamline the entire wrapping process and semi-automatic machines that require some manual input. Industrial coil wrapping machines are particularly suited for sectors like construction, automotive, and manufacturing, where steel strips are frequently exposed to adverse conditions during storage and shipping.

Importance of High-Performance Coil Wrapping Machines

A high-performance coil wrapping machine enhances productivity and reliability on the production line. With advanced automation, faster wrapping speeds, and durable construction, these machines ensure consistent, high-quality wrapping that keeps steel coils protected throughout their lifecycle. High-performance machines also reduce waste by applying precise amounts of wrapping material, which helps lower operational costs while maximizing product safety.

Key Factors to Consider When Choosing a Coil Wrapping Machine

When selecting a coil wrapping machine, it’s crucial to consider various factors that impact long-term efficiency, reliability, and adaptability. Here’s a closer look at each of these essential criteria:

1. Coil Size and Weight Capacity

The first thing to evaluate is whether the machine can handle the specific dimensions and weights of the steel coils your operation processes. High-performance coil wrapping machines are typically built to accommodate a wide range of coil sizes and can handle coils weighing thousands of pounds. Ensure that the machine can support the maximum weight capacity needed in your facility to avoid overloading the equipment, which could lead to safety hazards or mechanical breakdowns.

2. Speed and Efficiency

A high wrapping speed is essential in fast-paced production environments, where productivity depends on the ability to wrap coils quickly and effectively. Many high-performance machines are designed to offer faster wrapping speeds, reducing downtime and improving throughput. However, it’s essential to choose a machine that balances speed with precision, ensuring that the wrapping material is applied smoothly and securely.

3. Flexibility and Adjustability

In modern manufacturing, flexibility is key. High-performance coil wrapping machines are often built to handle a variety of coil diameters and widths, allowing for greater adaptability to changing production demands. Adjustable settings, including wrap tension and overlap, offer better control over the wrapping process, which is especially beneficial when working with different coil sizes or sensitive materials.

4. Quality of Wrapping Materials

The quality of materials compatible with a coil wrapping machine can significantly affect the outcome. High-performance machines are often designed to work with various protective materials, such as stretch film, VCI paper, and HDPE (High-Density Polyethylene) sheeting. The ability to choose the right material allows operators to ensure optimal protection for each coil, whether it’s destined for long-term storage or immediate use in production.

5. Automation and Control Features

One of the most valuable aspects of high-performance machines is their advanced automation capabilities. Automated coil wrapping machines offer programmable settings for consistent, hands-free operation, which minimizes the risk of operator error. Touchscreen controls, pre-programmable wrap cycles, and automatic film cut-off options make these machines user-friendly and increase operational speed and reliability. Look for machines with flexible control options that allow easy adjustments for different types of coils.

6. Safety Features

High-performance machines are equipped with safety features to ensure operator protection. Emergency stop buttons, motion sensors, and safety guards are essential components in any industrial machine, preventing accidents and enabling safe operation in high-demand settings. OSHA-compliant safety protocols and mechanical locks can further ensure that the equipment operates safely even under heavy loads.

7. Energy Efficiency

For facilities focused on cost-effectiveness and sustainability, energy efficiency is a critical consideration. High-performance coil wrapping machines often incorporate energy-saving technologies, such as motor power regulation and automated shut-off mechanisms, which reduce overall energy consumption. Efficient machines not only lower your electricity bills but also reduce the carbon footprint of your operations.

8. Maintenance and Ease of Service

Maintenance is crucial for keeping high-performance coil wrapping machines running smoothly. Opt for machines designed with easy access to critical components, as this simplifies both routine checks and repairs. High-performance models often include self-diagnostics features that alert operators to potential issues before they become major problems, minimizing downtime and maintenance costs. Additionally, select a model from a vendor known for reliable service and spare parts availability.

9. Vendor Support and Reliability

When investing in a high-performance coil wrapping machine, it’s essential to choose a reputable vendor with proven reliability. Look for manufacturers that offer robust warranties, flexible support plans, and fast response times. A trustworthy vendor will provide necessary training for your team, ensuring they know how to operate the machine effectively and troubleshoot minor issues, thereby maximizing the equipment’s lifespan.

Advantages of a High-Performance Coil Wrapping Machine

A high-performance coil wrapping machine can significantly boost your operations:

-

Enhanced Productivity: Automated features and high-speed wrapping enable operators to wrap more coils per hour, increasing productivity.

-

Reduced Material Waste: Precise application of wrapping materials minimizes waste and lowers long-term costs.

-

Improved Product Protection: Consistent wrapping quality ensures each coil is adequately protected against environmental factors, reducing damage rates.

Choosing the Right Coil Wrapping Machine for Your Needs

Selecting the right coil wrapping machine involves aligning its capabilities with your specific production needs. Start by assessing your production volume, coil dimensions, and the types of materials used for wrapping. Next, consider the machine’s operational features, such as speed, automation, and flexibility, which play critical roles in meeting your production demands. Lastly, choose a reliable vendor offering strong support and warranties for added peace of mind.

Emerging Technologies in Coil Wrapping Machines

As technology advances, coil wrapping machines are integrating new features like IoT connectivity, allowing for real-time monitoring and predictive maintenance. Advanced sensors help monitor machine wear and tear, alerting operators to potential issues before they lead to downtime. These innovations contribute to better equipment longevity and higher efficiency, aligning with the Industry 4.0 shift toward smart manufacturing.

Conclusion

Investing in a high-performance coil wrapping machine for steel strips can revolutionize your production line, providing faster, more reliable, and cost-effective wrapping solutions. From size and weight capacity to automation and energy efficiency, each feature plays a vital role in ensuring that the machine fits seamlessly into your operations. By focusing on these essential criteria, you’ll find a coil wrapping machine that not only meets your current needs but also scales with future growth.

FAQs

-

What materials are compatible with coil wrapping machines?

-

Coil wrapping machines are compatible with various protective materials, such as stretch film, VCI paper, and HDPE sheeting, providing flexibility in product protection.

-

Can I wrap coils of various sizes on one machine?

-

Yes, many high-performance coil wrapping machines offer adjustable settings to handle different coil sizes and weights, making them versatile for varied production needs.

-

How often should a coil wrapping machine be serviced?

-

Regular maintenance is recommended, with frequency depending on the machine’s usage and manufacturer guidelines. Many high-performance models include self-diagnostics to assist in maintenance scheduling.

-

What is the average cost of a high-performance coil wrapping machine?

-

Costs vary based on the machine’s capacity and features, generally ranging from $10,000 to $50,000 or more for advanced, fully automated models.

-

How do automation features impact production speed?

-

Automated features streamline the wrapping process, allowing for faster, more consistent wraps, which in turn enhances production speed and efficiency.