Home > Products > Show Room > Coil Wrapping Machine >

Fhopepack Innovation

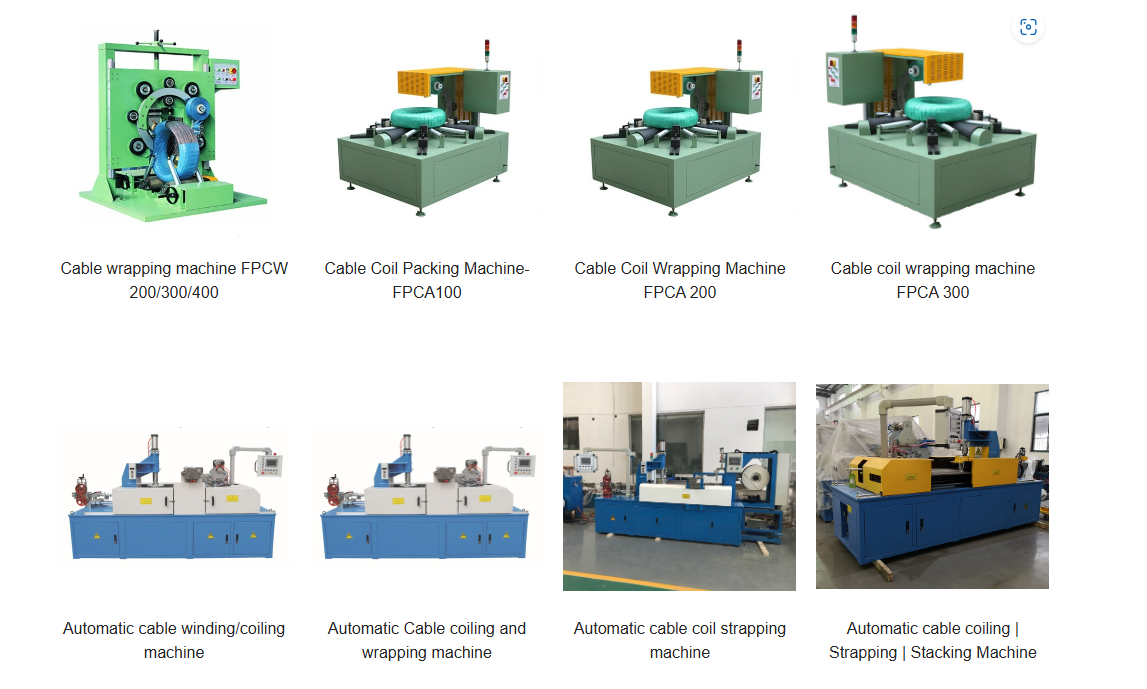

Coil Wrapping Machine For Cable Coil

The Coil Wrapping Machine for Cable Coils is an advanced packaging solution that ensures cables are wrapped securely and evenly. Ideal for maintaining product integrity, it offers adjustable speed and wrap settings, minimizing handling time and enhancing protection for cable coils in storage and transit.