Some Common Issues About Coil Wrapping Machines That You Need to Know

Introduction

Coil wrapping machines are indispensable in industries that deal with heavy and delicate materials. From steel coils to electrical wires, these machines ensure that products are securely wrapped and protected for storage or transportation. Their ability to provide consistent wrapping and safeguard goods against damage has made them a cornerstone of industrial packaging.

The significance of coil wrapping machines in industrial applications cannot be overstated. They are used in a wide range of sectors, including manufacturing, logistics, and shipping. By automating the wrapping process, these machines reduce labor costs, improve efficiency, and maintain uniformity. However, like any piece of machinery, coil wrapping machines are not immune to problems, and understanding these issues is key to ensuring optimal performance.

In this article, we’ll delve into the common issues associated with coil wrapping machines. From mechanical failures to operator errors, we’ll explore the root causes and provide insights into troubleshooting and prevention. By the end, you’ll have a clearer understanding of how to maintain and maximize the performance of your coil wrapping equipment.

Understanding Coil Wrapping Machines

What is a Coil Wrapping Machine?

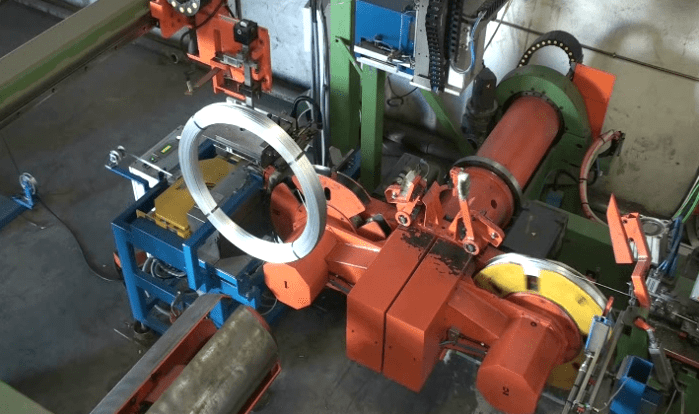

A coil wrapping machine is a specialized piece of equipment designed to wrap coils of various materials, such as wires, cables, steel, or other industrial products. These machines use different types of wrapping materials like plastic films, paper, or stretch wraps to encase the coils, ensuring their protection during storage or transportation.

There are several types of coil wrapping machines tailored to specific applications:

-

Horizontal Coil Wrapping Machines – These are commonly used for wrapping larger, heavier coils like steel and aluminum.

-

Vertical Coil Wrapping Machines – Designed for smaller, more delicate coils like cables or wires.

-

Automatic vs. Semi-Automatic Machines – Automatic machines require minimal operator intervention, while semi-automatic machines need manual adjustments for some processes.

Each type is suited to particular needs, and choosing the right one depends on the material, size, and production requirements of your business.

Key Components of Coil Wrapping Machines

Understanding the core components of a coil wrapping machine is essential for maintaining its functionality:

-

Rollers: These support and rotate the coils during the wrapping process. Misaligned or damaged rollers can disrupt operations.

-

Sensors: Sensors monitor and guide the wrapping process, ensuring accuracy and efficiency. They detect coil dimensions and position the wrapping material accordingly.

-

Control Panels: Modern machines are equipped with digital control panels that allow operators to adjust settings such as speed, tension, and material feed. Faulty control panels can lead to improper wrapping.

-

Wrapping Materials: The choice of material plays a critical role. High-quality plastic film, stretch wraps, or paper are typically used to provide adequate protection and stability.

These components work in tandem to achieve precise and consistent wrapping. Regular inspection and maintenance are crucial to avoid breakdowns.

Benefits of Using Coil Wrapping Machines

The advantages of coil wrapping machines extend beyond just saving time and labor:

-

Efficiency and Consistency: These machines automate the wrapping process, ensuring that each coil is uniformly wrapped. This reduces human error and increases production speed.

-

Protection of Products: Wrapped coils are protected from environmental factors such as moisture, dust, and physical damage, which is particularly important for materials stored over long periods or shipped across long distances.

-

Cost Savings: By minimizing material waste and reducing the need for manual labor, businesses can achieve significant cost savings in the long run.

-

Enhanced Product Presentation: Professionally wrapped products create a better impression on customers and clients, boosting brand reputation.

With these benefits in mind, it’s clear that coil wrapping machines are a worthy investment for any industry dealing with coiled materials.

Common Issues with Coil Wrapping Machines

Mechanical Failures

Mechanical failures are one of the most common problems encountered with coil wrapping machines:

-

Misaligned Rollers: Rollers that are not properly aligned can cause irregular wrapping or even damage the coil. Misalignment often occurs due to wear and tear or improper adjustments.

-

Wear and Tear on Machine Components: Over time, parts like rollers, gears, and bearings may wear out, leading to decreased performance and frequent breakdowns. Regular lubrication and timely replacement of worn parts can prevent such issues.

Electrical Problems

Electrical malfunctions can halt production and require immediate attention:

-

Sensor Malfunctions: Sensors are vital for guiding the wrapping process. Faulty sensors may fail to detect the coil’s position or dimensions, leading to uneven wrapping or errors.

-

Issues with Control Systems: Problems with the control panel, such as unresponsive buttons or software glitches, can make it difficult to adjust settings and control the machine. These issues often require professional repair or replacement.

Wrapping Material Issues

The choice and handling of wrapping materials can also cause problems:

-

Quality of Materials: Low-quality plastic films or wraps may tear easily, compromising the integrity of the wrapping.

-

Problems with Film Tension: Incorrect tension settings can result in loose or overly tight wrapping, both of which are undesirable. Loose wrapping fails to protect the coil, while tight wrapping can damage it.

Regularly inspecting and replacing wrapping materials and adjusting tension controls can help mitigate these issues.

Operator Errors

Human error is another significant factor in coil wrapping machine issues:

-

Lack of Training: Inexperienced operators may struggle with adjusting machine settings or troubleshooting basic problems, leading to inefficiencies and downtime.

-

Incorrect Machine Settings: Setting the wrong parameters for coil dimensions, speed, or material feed can result in poor wrapping quality or even damage to the machine and product.

Investing in proper training for operators and implementing a clear set of guidelines can greatly reduce these errors.

Troubleshooting Coil Wrapping Machines

Efficiently troubleshooting coil wrapping machines requires a systematic approach to identify and resolve issues. Addressing problems promptly minimizes downtime, enhances productivity, and ensures long-term reliability. Below are detailed steps and solutions for common challenges faced by operators.

Identifying the Problem

A clear understanding of the root cause is crucial for effective troubleshooting. Here’s how you can identify problems efficiently:

-

Conducting Regular Inspections

Frequent inspections are the first step in identifying potential issues. Examine machine components like rollers, belts, sensors, and wrapping materials for visible wear and tear. Pay attention to unusual noises, uneven wrapping, or machine vibrations, as these may indicate underlying mechanical problems.

-

Using Diagnostic Tools

Advanced diagnostic tools and software are invaluable in pinpointing specific issues. Many modern coil wrapping machines come equipped with built-in diagnostic systems that alert operators to malfunctions. For older machines, portable diagnostic tools like multimeters, thermal imaging cameras, and alignment gauges can help detect electrical, thermal, and mechanical anomalies.

Solutions for Mechanical Failures

Mechanical problems are often the most common issues with coil wrapping machines. Addressing these quickly is key to keeping operations running smoothly.

-

Lubrication and Realignment

Proper lubrication reduces friction and prevents excessive wear on moving parts such as rollers, bearings, and gears. Misaligned rollers can cause uneven wrapping or coil damage. Regularly check roller alignment and make necessary adjustments to maintain optimal performance.

-

Replacing Worn-Out Parts

Over time, components such as belts, rollers, and gears wear out. Proactively replacing these parts before they fail completely ensures uninterrupted operation. Keep a stock of essential spare parts to minimize downtime.

Fixing Electrical Issues

Electrical failures can disrupt the wrapping process and often require immediate attention.

-

Resetting Sensors and Recalibrating Systems

Malfunctioning sensors may fail to detect coil dimensions or position accurately, leading to errors. Resetting sensors and recalibrating the system often resolves these issues. Follow the manufacturer’s instructions for proper sensor alignment and calibration.

-

Professional Repairs

Complex electrical problems, such as circuit board failures or unresponsive control panels, require professional intervention. Always consult certified technicians to handle intricate repairs, as improper fixes can exacerbate the issue.

Addressing Wrapping Material Problems

The choice and handling of wrapping materials directly affect the performance of the machine and the quality of the final product.

-

Choosing High-Quality Films

Low-quality wrapping materials can tear or stretch unevenly, compromising the integrity of the wrapping. Invest in high-quality films or wraps that are compatible with your machine’s specifications.

-

Adjusting Tension Controls

Incorrect tension settings can lead to loose or overly tight wrapping. Use the control panel to adjust film tension as per the product requirements, ensuring a secure and uniform wrap.

Maintenance Tips to Prevent Common Issues

Preventive maintenance is the most effective way to reduce machine downtime and prolong its lifespan. Here are actionable maintenance tips:

Routine Inspections

-

Checklist for Regular Maintenance

Create a detailed maintenance checklist covering key components such as rollers, belts, gears, sensors, and wrapping material feeds. Regularly inspect for signs of wear, alignment issues, or loose connections.

-

Importance of Preventive Measures

Preventive maintenance not only reduces the likelihood of sudden breakdowns but also improves the machine’s overall efficiency. Schedule routine maintenance sessions to identify and address minor issues before they escalate.

Proper Cleaning

-

Cleaning Machine Components

Dust, debris, and material residue can accumulate on machine components, hindering their performance. Clean rollers, sensors, and other parts using appropriate cleaning agents and tools recommended by the manufacturer.

-

Avoiding Dust and Debris Buildup

Keep the workspace clean and free from dust to prevent debris from entering the machine. Install protective covers or enclosures for sensitive components like sensors and electrical circuits.

Staff Training

-

Importance of Skilled Operators

Well-trained operators are less likely to make errors, ensuring smoother operations. A skilled operator can also identify potential issues early and take corrective actions before significant damage occurs.

-

Training Programs and Certifications

Provide comprehensive training programs for your team, focusing on machine operation, maintenance, and troubleshooting. Encourage operators to obtain certifications that validate their expertise and enhance their skill set.

Upgrading and Modernizing Coil Wrapping Machines

Investing in upgrades and modern technology can transform the efficiency and reliability of coil wrapping machines, ensuring they remain competitive in evolving industrial landscapes.

Why Upgrade?

-

Benefits of Modern Technology

Upgraded machines incorporate advanced technologies such as IoT-enabled sensors, automated controls, and real-time monitoring. These features enhance accuracy, reduce human intervention, and improve overall efficiency.

-

Improved Efficiency and Performance

Modern machines are faster, more energy-efficient, and capable of handling complex tasks with greater precision. Upgrading reduces downtime and boosts productivity.

Choosing the Right Upgrades

-

Smart Sensors and Automation

Add smart sensors for real-time monitoring and feedback. Automation can further streamline operations, minimizing errors and improving consistency.

-

Energy-Efficient Components

Replacing older, energy-intensive components with modern, energy-efficient alternatives reduces operational costs and aligns with sustainability goals.

Costs vs. Benefits

-

ROI of Upgrading Machines

While upgrading involves initial costs, the return on investment (ROI) is significant. Improved productivity, reduced maintenance costs, and higher product quality offset the expenditure over time.

-

Long-Term Advantages

Modernized machines are future-proof, capable of adapting to new materials and processes. They also require less frequent maintenance, further reducing operational expenses.

When to Seek Professional Help

Coil wrapping machines are complex pieces of equipment, and while regular maintenance can address many issues, some problems require expert attention. Knowing when to seek professional help can save you time, money, and unnecessary frustration.

Signs You Need Expert Assistance

-

Persistent Mechanical Problems

If you’re repeatedly facing mechanical issues such as misaligned rollers, jammed components, or inconsistent wrapping despite routine maintenance, it’s time to involve a professional. Persistent problems can indicate deeper issues, like damaged internal components or structural misalignments that require advanced tools and expertise to fix.

-

Complex Electrical Failures

Electrical issues, such as malfunctioning control panels, unresponsive sensors, or frequent power failures, are often beyond the scope of basic troubleshooting. These failures may stem from wiring issues, circuit board damage, or software glitches, all of which require a skilled technician to diagnose and repair.

Finding Reliable Service Providers

-

Tips for Choosing a Technician

Finding the right service provider ensures that your machine is in capable hands:

-

Experience: Look for technicians or companies specializing in coil wrapping machines with a proven track record of resolving similar issues.

-

Certifications: Certified professionals are more likely to adhere to industry standards, ensuring high-quality service.

-

Customer Reviews: Check reviews and testimonials to gauge the provider’s reliability and performance.

-

Importance of Warranties and Guarantees

Professional repairs should come with warranties or guarantees to protect your investment. These not only provide peace of mind but also ensure accountability from the service provider. Always confirm warranty details before authorizing repairs.

The Future of Coil Wrapping Machines

The packaging industry is evolving rapidly, and coil wrapping machines are no exception. Innovations in technology and sustainability are reshaping how these machines operate, paving the way for greater efficiency and environmental responsibility.

Trends in Coil Wrapping Technology

-

Integration with IoT

The Internet of Things (IoT) is revolutionizing industrial machinery by enabling real-time monitoring and control. IoT-enabled coil wrapping machines can:

-

Collect performance data to identify inefficiencies.

-

Send alerts about potential issues, reducing downtime.

-

Allow remote operation and diagnostics, improving convenience.

-

Enhanced Safety Features

Modern machines are being designed with advanced safety features to protect operators and reduce workplace accidents. Features such as automated emergency stops, improved sensor precision, and tamper-proof controls are becoming standard, ensuring a safer and more reliable working environment.

Sustainability in Wrapping Solutions

-

Eco-Friendly Materials

The push for sustainable packaging has led to the development of biodegradable and recyclable wrapping materials. These materials not only reduce environmental impact but also appeal to eco-conscious consumers and clients.

-

Energy-Saving Designs

Energy efficiency is a top priority in modern coil wrapping machines. Advances such as energy-efficient motors, optimized power consumption, and low-friction components reduce operational costs and carbon footprints, aligning with global sustainability goals.

Conclusion

Coil wrapping machines are essential for protecting and packaging coiled materials, but their effectiveness depends on regular maintenance, timely troubleshooting, and the adoption of modern technology.

-

Recap of Key Points: We explored common issues with coil wrapping machines, including mechanical, electrical, and material-related problems. Solutions such as routine inspections, proper training, and upgrading components were discussed to enhance efficiency.

-

Importance of Addressing Issues: Ignoring problems can lead to costly downtime and damage. Timely intervention, whether through troubleshooting or professional repairs, is crucial for maintaining optimal performance.

-

Final Thoughts: Embracing trends like IoT integration and sustainable materials will ensure your coil wrapping machines remain competitive and eco-friendly in the years to come.

By understanding these aspects, you can make informed decisions to prolong the life of your equipment and enhance your overall operations.