Coil Wrapping Machines for Copper Coils: Ensuring Protection and Durability

Coil wrapping machines for copper coils are essential for maintaining product integrity during storage and transport. These machines come in various configurations, each designed to accommodate production volume, coil size, and automation needs. Below is an overview of the primary types of copper coil wrapping machines, each suited to different operational requirements:

Rotary Arm Wrapping Machines

Rotary arm wrapping machines are ideal for copper coils stored and transported on pallets in an “eye to sky” orientation, with the center of the coil facing upward. In these machines, a rotary arm moves around the stationary coil, applying a consistent wrap of protective film. This configuration is particularly beneficial for large, heavy copper coils that need secure wrapping without being rotated. By keeping the coil steady on a pallet, rotary arm machines minimize the risk of deformation or damage and make handling with forklifts easier, making them suitable for high-volume applications where robust protection is needed.

Semi-Automatic Coil Wrapping Machines

Semi-automatic machines offer a balance between manual control and automation, making them suitable for mid-volume production facilities. These machines require some initial setup, such as loading the coil and securing the film, but automate the wrapping process itself. This setup provides a high level of efficiency without fully automating the process. Semi-automatic machines offer reliable wrapping with precise film tension, ensuring even coverage across the copper coil without overstretching or causing material damage. This type is cost-effective and adaptable, ideal for mid-scale production needs while allowing for operator control.

Film Covering and Box Packing Machines

For copper coils that require additional protection, film covering and box packing machines offer a comprehensive solution. These machines wrap the coil in protective film, often with vapor corrosion inhibitors (VCI) or stretch film, and then package it in a box for maximum protection. This method is ideal for coils sensitive to environmental factors or requiring high levels of protection during transport. The box packing option adds an extra layer of impact resistance, making it particularly beneficial for long-haul transportation or export packaging needs.

Automatic Master Coil Wrappers

Automatic master coil wrappers are tailored for high-volume, large-diameter copper coils and require minimal human involvement. Equipped with advanced automation features like conveyor systems for coil infeeding and out-feeding, film length calculation, and automatic cutting, these machines streamline the wrapping process and reduce labor costs. Automatic master coil wrappers can handle larger coil sizes and provide consistent, high-quality wraps, making them suitable for facilities with high output demands. Operators can customize parameters for wrap tension, film type, and wrapping speed, ensuring optimal wrapping based on specific coil sizes and types.

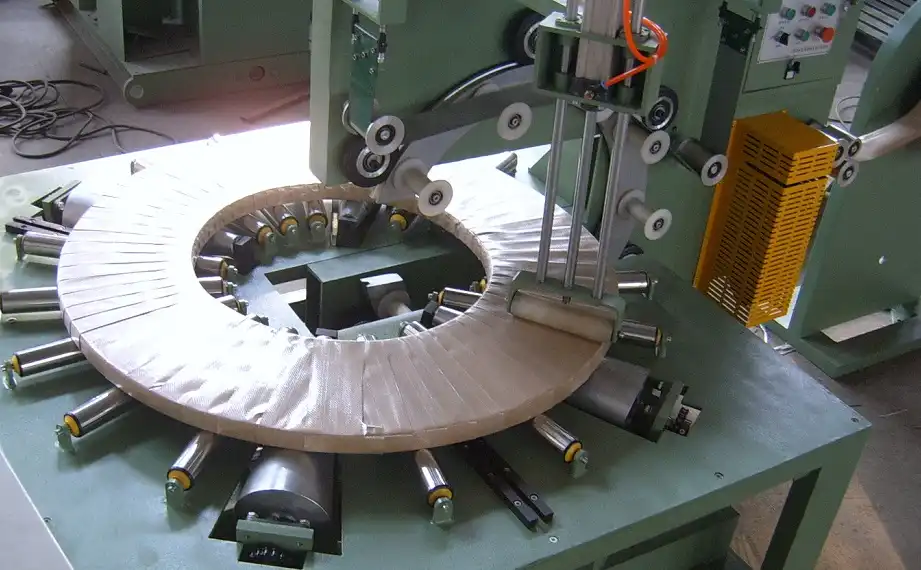

Horizontal Wrapping Machines

Horizontal wrapping machines are commonly used for large-diameter copper coils. In these machines, coils are loaded and wrapped while lying flat, simplifying the handling of heavy coils. Often featuring a rotating ring that moves around the circumference of the coil, horizontal wrapping machines apply film with consistent tension. This configuration is ideal for high-output facilities where large coils are frequently handled, as it allows for efficient wrapping and enhanced stability for bulky or heavy coils.

Vertical Wrapping Machines

Vertical wrapping machines are compact and suitable for smaller to mid-sized copper coils. With a smaller footprint, they’re ideal for facilities with limited space or budget constraints. These machines hold the coil in an upright position, which minimizes floor space requirements and simplifies loading and unloading. Vertical wrapping machines are perfect for companies with medium to low production volumes that still require reliable, consistent wrapping for copper coils. This solution is both cost-effective and space-efficient, allowing businesses to maximize productivity in tighter spaces without compromising wrapping quality.

Parameters:

Model

|

Voltage (V/Hz)

|

Power (KW)

|

Coil ID (mm)

|

Coil OD (mm)

|

Coil Width (mm)

|

Coil Weight (Kg)

|

Packing Material

|

|

FPW-300

|

customized

|

1.5

|

508-610

|

600-1200

|

100-300

|

20-1000

|

PVC/LLDPE/PE/PAPER/HDPE

|

|

FPS-400

|

customized

|

4.0

|

508-610

|

800-1400

|

100-400

|

100-2000

|

PVC/LLDPE/PE/PAPER/HDPE

|

|

FPS-500

|

customizable

|

2.0

|

508-610

|

700-1400

|

200-500

|

100-1000

|

PVC/LLDPE/PE/PAPER/HDPE

|

|

FPS-600

|

customizable

|

7.5

|

700-1100

|

1000-1500

|

200-600

|

200-2000

|

Crepe paper/plastic knit tape

|

|

FPS-800

|

customizable

|

7.5

|

508

|

800-1400

|

400-800

|

200-1000

|

PVC/LLDPE/PE/PAPER/HDPE

|

|

FPCA-1000

|

customizable

|

4.5

|

508-610

|

700-1600

|

20-400

|

100-2000

|

PVC/LLDPE/PE/PAPER/HDPE

|

|