Coil Wrapping Machine for Steel Coils: Benefits, Types, and Industrial Applications

Introduction to Coil Wrapping Machines for Steel Coils

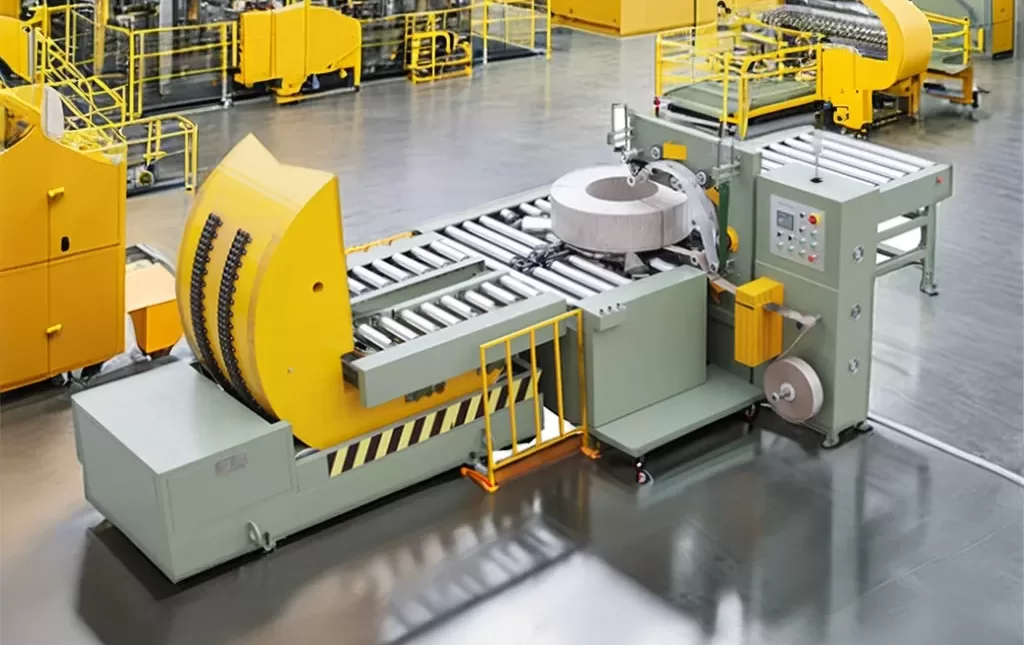

In the world of steel manufacturing, packaging and handling are essential steps for ensuring product quality and safety. Coil wrapping machines for steel coils have revolutionized these processes, providing protection, efficiency, and reliability. These machines apply protective films around steel coils, securing them for storage or transport. With advanced automation, today’s coil wrapping machines enhance both productivity and safety, making them essential equipment in modern steel mills and distribution centers.

Understanding the Need for Coil Wrapping in Steel Industries

Steel coils are prone to damage from moisture, dust, and physical impact, making protective wrapping vital. During transport and storage, unwrapped coils can rust, suffer from corrosion, or even deform under poor handling conditions. Wrapping helps maintain the integrity of the steel, preserving its quality and extending its shelf life. Wrapping also serves as a form of branding, providing an aesthetic finish that appeals to customers while allowing companies to add labeling or logos for easy identification.

How Coil Wrapping Machines Work

Coil wrapping machines function by rotating steel coils on a turntable while a roll of protective film encircles the coil, ensuring even coverage. Key components in these machines include:

-

Turntable: Holds and rotates the coil, allowing for even application of wrapping.

-

Film Dispenser: Controls film tension and speed, ensuring secure and uniform wrapping.

-

Control System: Allows operators to set specific wrapping parameters, such as wrap tension and speed.

These components work together to create a consistent, tightly wrapped product that resists environmental exposure and physical damage.

Horizontal Wrapping Machines are often used for large steel coils, while Vertical Wrapping Machines are better suited for smaller coils or applications with limited space.

Features of High-Quality Coil Wrapping Machines

A high-quality coil wrapping machine for steel applications should offer:

-

Durability: Built with industrial-grade materials to withstand heavy use.

-

Precision Wrapping: Evenly applies wrap to prevent loose ends or wrinkles.

-

Speed Control: Adjustable speed for customizing wrapping based on coil size and production needs.

Additionally, machines with advanced safety features, such as emergency stop buttons and protective guards, ensure operator safety while maintaining high efficiency.

Benefits of Using Coil Wrapping Machines for Steel Coils

Using coil wrapping machines offers many advantages:

-

Corrosion Protection: Wrapping prevents exposure to air and moisture, which can lead to rust.

-

Dust and Dirt Prevention: Secures the coil from environmental contaminants.

-

Enhanced Efficiency: Automated machines reduce labor costs and shorten wrapping times.

-

Improved Product Presentation: Neatly wrapped coils appear professional and convey quality to customers.

These benefits make coil wrapping machines a strategic investment for companies aiming to improve their production quality and customer satisfaction.

Automated Coil Wrapping Machines for Increased Productivity

Automation in coil wrapping significantly enhances productivity by reducing manual handling and increasing wrapping speed. Automated machines can wrap coils with consistent tension and precision, decreasing the likelihood of damage during transport or storage. This reduction in manual intervention not only speeds up operations but also improves consistency, leading to higher-quality outcomes.

Material Options for Wrapping Steel Coils

The wrapping material is key to effective coil protection. Common options include:

-

Stretch Film: Provides a secure wrap and is flexible enough to cover irregular surfaces.

-

Shrink Film: Applied with heat, it conforms tightly to the coil, offering excellent protection.

-

Polyethylene: Ideal for heavy-duty protection and resists punctures or tears.

Choosing the right material depends on factors like coil size, transportation conditions, and storage environment.

FAQs

-

How does a coil wrapping machine differ for steel compared to other materials?

-

Steel coils require heavier-duty wrapping materials to prevent rust and damage, making specialized wrapping essential.

-

What materials are best for wrapping steel coils?

-

Common materials include stretch and shrink films, as well as durable polyethylene wraps, chosen for their protective qualities.

-

Can one machine handle different coil sizes?

-

Yes, many coil wrapping machines are adjustable and can handle a range of coil sizes, making them versatile for various needs.

-

What are the environmental benefits of using coil wrapping machines?

-

Coil wrapping reduces waste and protects products, leading to fewer replacements and less material use, thus conserving resources.

-

How often should coil wrapping machines undergo maintenance?

-

Daily inspections are recommended, with more extensive maintenance on a weekly and monthly basis to ensure peak performance.