Enhancing Coil Packaging Efficiency with a Trolley-Equipped Wrapping System

When it comes to coil packaging, efficiency, protection, and flexibility are non-negotiable. For fabricators dealing with heavy steel coils, integrating mobility into the packaging process can offer a distinct advantage. That’s where a coil wrapping machine with a trolley system stands out—combining robust packaging performance with improved logistics and operational safety on the shop floor.

1. Mobility That Matches the Pace of Production

In fast-paced manufacturing environments, adaptability is key. A trolley-mounted coil wrapping machine allows operators to bring the equipment to the coil, not the other way around. This eliminates the need for repositioning heavy coils just to access fixed machinery. Especially in large-scale facilities or warehouses, this added mobility reduces downtime and optimizes space utilization—boosting throughput without expanding footprint.

2. Flexibility Across Packaging Lines

Whether you're running multiple product lines or dealing with varying coil sizes, the trolley system introduces a level of versatility that’s hard to match. The same coil wrapping machine can be easily deployed across different stations, eliminating the need for redundant machinery. This cross-line flexibility translates into lower capital investment, more efficient use of floor space, and simplified training for operators.

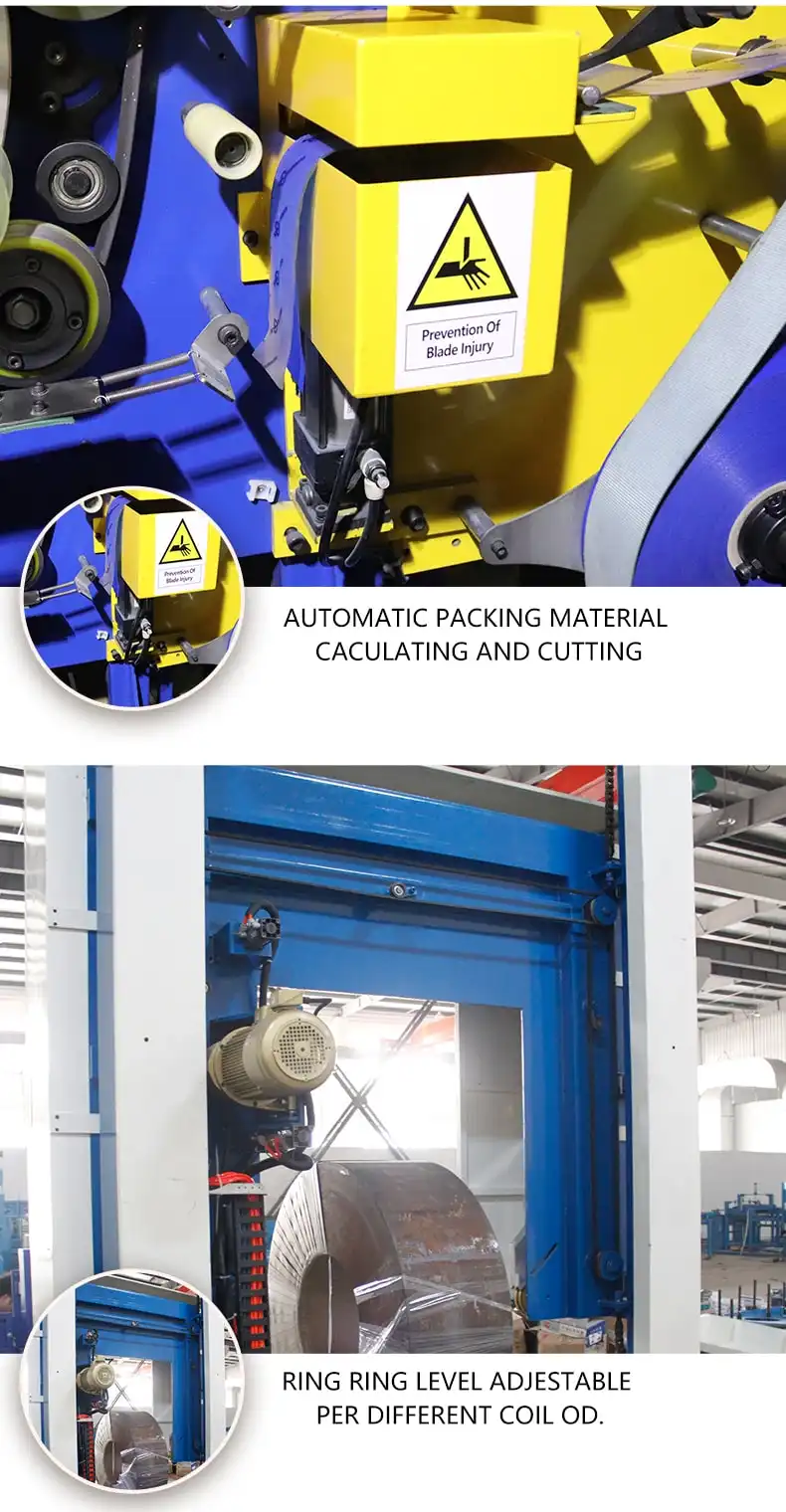

3. Built-In Safety Advantage

Transporting heavy coils is a known risk factor in industrial settings. By enabling the coil packaging machine to be moved via trolley rather than relocating the load, the risk of back strain, equipment damage, and workplace injuries is significantly reduced. The system contributes to a safer, more ergonomic working environment—one that aligns with best practices in material handling and worker safety.

4. Streamlined Maintenance and Serviceability

Downtime for maintenance is inevitable—but how it's handled can make a difference. A trolley-equipped coil wrapping system can be repositioned for easy access during servicing, keeping disruptions to a minimum. Instead of working around fixed installations, maintenance personnel can bring the machine to a designated service zone, improving both efficiency and care. The result: less production loss and extended equipment lifespan.

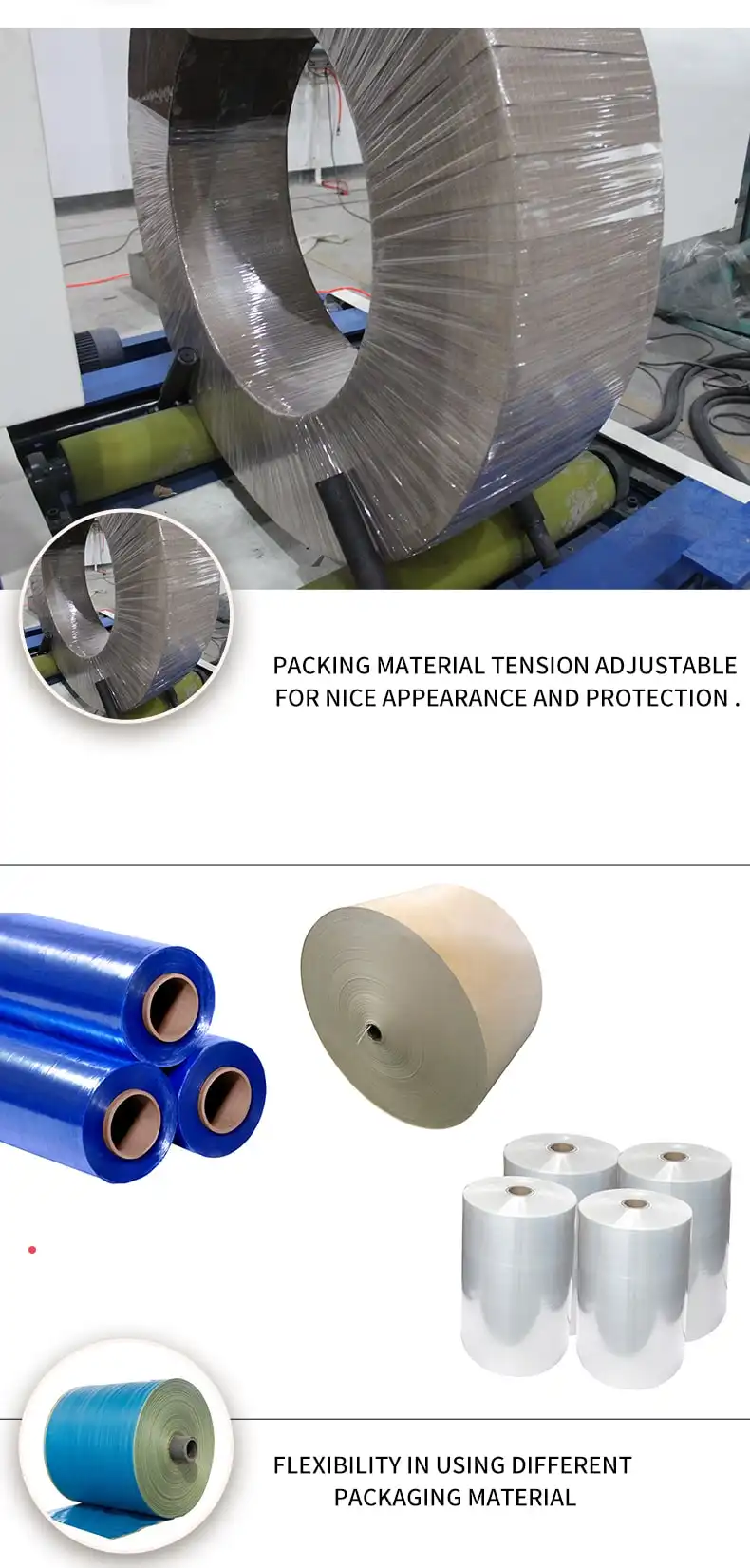

Final Thought: Mobility That Protects More Than Just the Coil

While coil protection remains the core function—achieved through tension-controlled film application and secure wrapping—the addition of a trolley doesn’t just move the machine. It moves the needle on what’s possible in modern coil packaging workflows: faster setup, safer operations, smarter use of space, and ultimately, a better bottom line.

Operational Advantages of Trolley-Equipped Coil Wrapping Machines

|

Feature

|

With Trolley System

|

Without Trolley System

|

|

Mobility

|

Machine can be moved to the coil location

|

Coil must be transported to fixed machine

|

|

Flexibility

|

Usable across multiple production lines

|

Dedicated to a single location or setup

|

|

Space Efficiency

|

Optimized floor layout with shared equipment use

|

Requires larger space or multiple units

|

|

Worker Safety

|

Minimizes manual coil handling and lifting

|

Higher risk of injury from material movement

|

|

Maintenance Accessibility

|

Machine can be serviced in designated zones

|

Technicians must work around fixed installations

|

|

Downtime Impact

|

Lower – machine can be relocated for servicing

|

Higher – maintenance may disrupt nearby processes

|

|

Capital Investment

|

Reduced – one machine serves multiple needs

|

Higher – need for additional machines per station

|

|

Protection Control

|

Maintains wrapping quality across locations

|

Consistent, but limited to one area

|

✅ Summary

This comparison highlights how integrating a trolley system with a coil wrapping machine not only improves the handling and protection of coils, but also adds significant value across production, safety, and maintenance workflows—making it a strategic upgrade for modern fabrication environments.