Choosing the Right Steel Coil Wrapping Machine: FPS-300 vs. FPCA-1200

Steel coil packaging is a critical process in industries where protection, efficiency, and durability are paramount. Two standout solutions—FPS-300 and FPCA-1200—represent innovation in steel coil wrapping technology. Each model offers unique features tailored to specific operational needs. In this article, we’ll explore their capabilities, helping you make an informed choice.

Both machines excel in safeguarding coils against environmental damage and transport risks, yet their designs cater to distinct industrial requirements. So, which one is the right fit for your business? Let’s dive in.

Steel coil packaging machines may seem similar at first glance, but their differences lie in the details. Each model introduces unique capabilities, from operational efficiencies to design versatility. Understanding these differences is key to selecting the best solution for your needs.

Efficiency, precision, and adaptability define modern coil wrapping solutions. These qualities distinguish the FPS-300 and FPCA-1200 models, each designed to tackle unique challenges in coil packaging. By comparing their features, you’ll uncover the specific advantages that align with your business goals.

Key Takeaway

When choosing between the FPS-300 and FPCA-1200, consider your specific operational needs. The FPS-300 is a space-efficient, cost-effective solution for vertical coil wrapping in compact environments. On the other hand, the FPCA-1200 excels in high-speed, automated horizontal wrapping for large-scale production lines. By aligning the machine's features with your business goals, you can enhance efficiency, protect your products, and maximize your ROI.

1. What makes the FPS-300 a standout option?

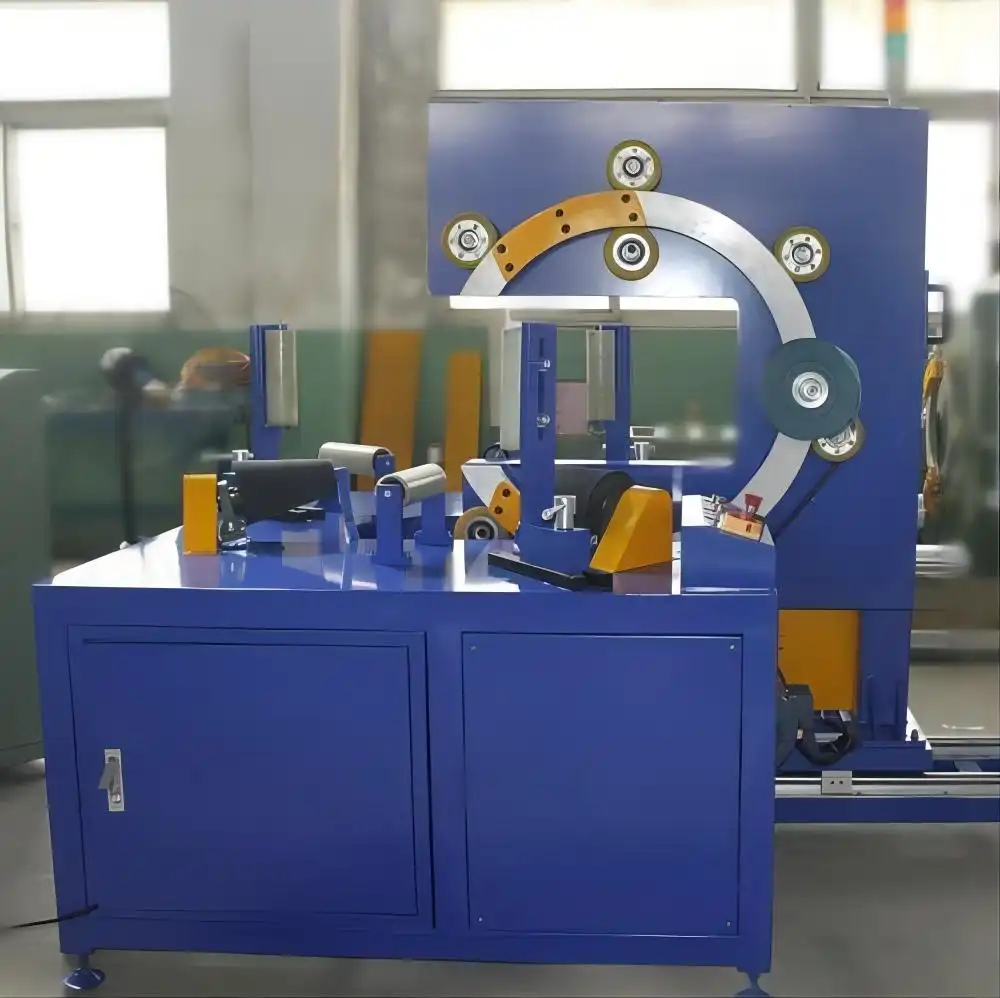

A compact powerhouse for steel coil protection

The FPS-300 stands out for its compact design, making it ideal for facilities with limited floor space. Despite its smaller footprint, this machine delivers high-speed wrapping with precision. Its robust structure ensures durability, even in demanding industrial environments.

Advanced wrapping technology in a compact design

This model employs a vertical wrapping system that tightly secures coils with durable stretch film or woven fabric. The FPS-300 includes adjustable tension controls, allowing operators to fine-tune the wrapping process based on coil specifications.

Designed for precision and longevity

Its construction integrates advanced control systems and heavy-duty rollers, ensuring consistent performance over time. The FPS-300 is an excellent choice for industries requiring robust protection in limited spaces, combining reliability with ease of operation.

2. How does the FPCA-1200 address horizontal packaging needs?

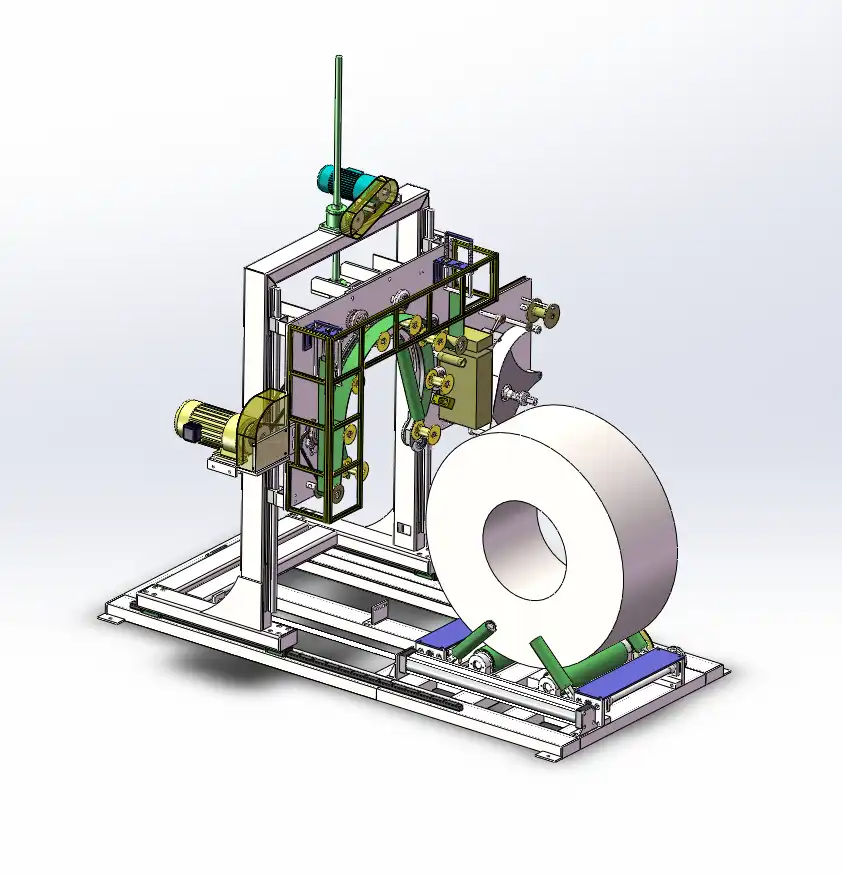

Streamlined solutions for horizontal steel coil packaging

The FPCA-1200 is tailored for horizontal wrapping, offering unmatched efficiency for handling large-diameter coils. Its design emphasizes throughput, making it a preferred choice for high-volume production lines where speed is critical.

Efficiency through horizontal design

The FPCA-1200’s horizontal wrapping mechanism eliminates the need for manual rotation, improving productivity. It seamlessly integrates with conveyor systems, enabling continuous operations without interruptions.

Tailored for large-scale operations

With features like automatic coil loading and unloading, the FPCA-1200 optimizes labor efficiency. Its customizable settings accommodate various coil sizes, making it versatile for diverse industrial applications.

3. Which model offers superior versatility and adaptability?

Comparing operational flexibility

The FPS-300 and FPCA-1200 excel in different operational contexts. The FPS-300 focuses on vertical precision, while the FPCA-1200 prioritizes horizontal efficiency. Both machines allow for customization, ensuring they meet specific industry demands.

Enhanced adaptability through design

The FPS-300’s compact frame suits facilities with space constraints, while the FPCA-1200’s horizontal wrapping system is ideal for expansive production lines. Both machines integrate seamlessly with conveyor systems, enhancing workflow automation.

Building solutions around your needs

Whether you prioritize space-saving features or large-scale throughput, these machines offer solutions tailored to your goals. Choosing the right model ensures optimal performance and long-term cost savings.

4. How to choose between the FPS-300 and FPCA-1200 for your operations?

Matching machine capabilities to business needs

Start by assessing your facility’s layout, production volume, and coil specifications. The FPS-300 is ideal for precision wrapping in compact spaces, while the FPCA-1200 supports horizontal wrapping for high-capacity production lines.

Balancing efficiency and cost

Consider the upfront investment versus long-term operational savings. The FPS-300’s simplicity and durability reduce maintenance costs, whereas the FPCA-1200 enhances efficiency in large-scale packaging lines, delivering faster ROI.

Your perfect coil wrapping solution

Both models represent cutting-edge technology, ensuring your steel coils are wrapped securely and efficiently. Evaluate your specific requirements to make the best choice for your business.

Comparison Table: FPS-300 vs. FPCA-1200

|

Feature

|

FPS-300

|

FPCA-1200

|

|

Machine Type

|

Vertical Steel Coil Wrapping Machine

|

Horizontal Steel Coil Wrapping Machine

|

|

Primary Application

|

Compact spaces; vertical wrapping for standard steel coils

|

Large-diameter coils; horizontal wrapping for high-volume operations

|

|

Wrapping Orientation

|

Vertical

|

Horizontal

|

|

Space Requirements

|

Compact, ideal for facilities with limited floor space

|

Larger footprint, suited for expansive production lines

|

|

Material Handling

|

Requires manual or conveyor-assisted loading

|

Fully automated coil loading and unloading

|

|

Integration

|

Can integrate with conveyor systems for automated workflows

|

Seamless conveyor integration for continuous operation

|

|

Key Features

|

- Adjustable tension control

- Heavy-duty rollers

- Compact design for smaller spaces

|

- Automatic loading/unloading

- Customizable settings for diverse coil sizes

- High-speed wrapping

|

|

Customization

|

Adjustable for different coil sizes and film tension

|

Highly customizable for various coil diameters and packaging needs

|

|

Speed

|

Moderate

|

High-speed wrapping suitable for high-capacity production

|

|

Durability

|

Heavy-duty frame for longevity in demanding environments

|

Reinforced structure for handling large and heavy steel coils

|

|

Industries Best Suited For

|

- Metalworking

- Manufacturing

- Distribution centers

|

- Steel processing

- Large-scale industrial manufacturing

|

|

Notable Advantage

|

Space-saving, cost-efficient solution

|

High throughput with advanced automation features

|

|

Ideal For

|

Businesses prioritizing space efficiency and cost-effectiveness

|

Operations requiring fast, automated, and large-scale coil packaging

|

This table simplifies the decision-making process, helping readers quickly identify which machine aligns with their operational needs.

Conclusion

When it comes to steel coil wrapping machines, the FPS-300 and FPCA-1200 each deliver unique benefits. Whether your focus is on maximizing floor space, achieving precision, or enhancing throughput, these models offer industry-leading solutions. Choosing the right machine means aligning its capabilities with your operational goals. For tailored advice and expert guidance, contact us to ensure you invest in the best solution for your needs.