Comprehensive Guide to Coil Wrapping Machines for Steel Wire Coils: Benefits, Types, and Applications

Introduction to Coil Wrapping Machines for Steel Wire Coils

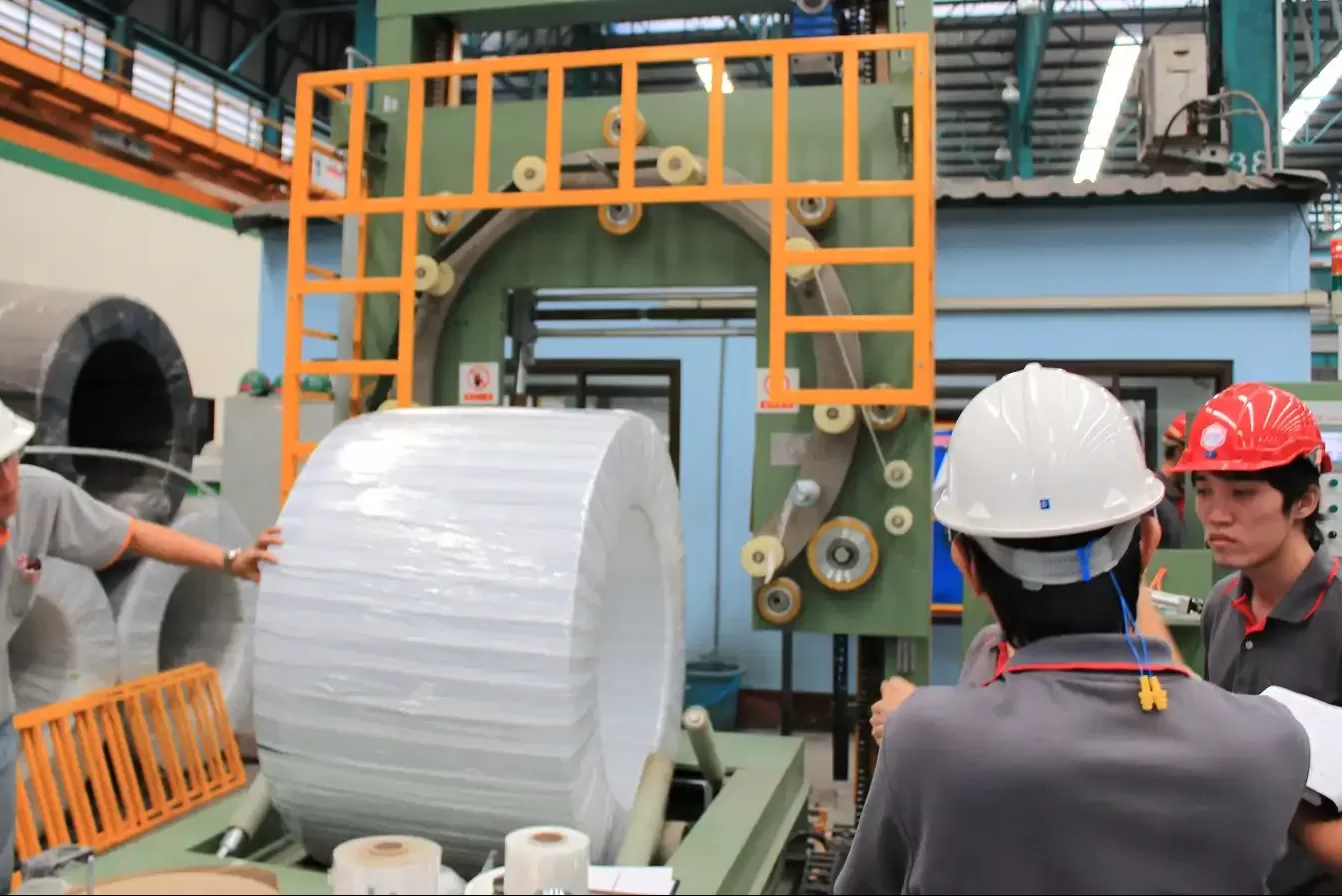

Coil wrapping machines are critical assets in industries that handle steel wire, ensuring coils are securely packaged and protected from environmental and physical damage. With growing demands in sectors like construction, manufacturing, and transportation, coil wrapping machines play a pivotal role in enhancing productivity and ensuring product quality. This guide explores how coil wrapping machines function, their benefits, and key considerations for industries relying on steel wire coils.

Understanding Coil Wrapping for Steel Wire Coils

Wrapping steel wire coils is essential for maintaining the integrity and usability of the steel, preventing damage from moisture, dust, and physical impact. Unlike other materials, steel wire requires extra protection due to its weight and potential corrosion when exposed. Wrapping machines designed for steel wire offer robust solutions that cater to these needs, making them indispensable in industrial packaging.

Importance of Coil Wrapping Machines in the Steel Industry

Coil wrapping machines streamline packaging by automating the process, which minimizes labor, reduces handling time, and enhances the overall efficiency of steel manufacturing and shipping operations. Moreover, proper wrapping provides vital protection during transit, storage, and handling, ensuring coils arrive at their destination in optimal condition. This helps avoid costly losses and protects the company's reputation by delivering quality products consistently.

Key Components of a Coil Wrapping Machine

Each coil wrapping machine is built with several critical components, each tailored to serve a specific function:

-

Turntable – Rotates the coil for efficient wrapping.

-

Film Dispenser – Ensures even application of the wrapping material.

-

Control Panel – Allows operators to set wrapping parameters.

-

Roller Conveyors – Facilitates coil movement before and after wrapping.

Customization options, such as adjustable turntables and adaptable dispensers, allow the machine to accommodate various coil sizes and shapes, making them versatile for different industrial needs.

Types of Coil Wrapping Machines for Steel Wire Coils

There are several types of coil wrapping machines tailored to specific industrial requirements:

-

Automatic Machines: Fully automated, reducing human intervention and maximizing efficiency.

-

Semi-Automatic Machines: Require manual setup but offer automated wrapping for smaller operations.

-

Horizontal Wrapping Machines: Ideal for large-diameter coils.

-

Vertical Wrapping Machines: Suited for compact, smaller coils.

Each type offers unique advantages based on the coil dimensions, production volume, and handling requirements of the facility, making it essential to choose the right machine for the job.

Working Mechanism of a Steel Wire Coil Wrapping Machine

A coil wrapping machine typically operates by placing the steel coil onto a turntable, where it is rotated as the wrapping material is applied. The operator, or automated control, initiates the wrapping process, and the machine applies the chosen film or material with uniform tension to avoid wrinkles or loose sections. Safety mechanisms, such as emergency stops and protective guards, ensure that operators are protected from any unexpected mishaps during operation.

Benefits of Using a Coil Wrapping Machine for Steel Wire Coils

The use of coil wrapping machines offers a multitude of benefits:

-

Cost Efficiency: Automation reduces labor costs and minimizes the need for rework due to damaged products.

-

Protection: Wrapped coils resist environmental elements, ensuring they stay rust-free and undamaged.

-

Improved Presentation: Neatly wrapped coils improve customer perceptions and ensure ease of identification with clear labeling.

Companies investing in these machines witness significant improvements in both operational efficiency and product quality, reinforcing the value of this technology in competitive markets.

Factors to Consider When Choosing a Steel Wire Coil Wrapping Machine

Below are key factors to evaluate in order to make an informed decision:

-

Coil Size and Weight: It’s vital to choose a machine that accommodates the dimensions and weight of the coils your operation handles. Different machines have varying capacities, and selecting one that meets your specifications will prevent potential operational issues and maintain wrapping quality.

-

Automation Level: Facilities with high production demands may benefit from fully automated coil wrapping machines, which streamline processes and reduce labor requirements. In contrast, smaller operations with lower throughput may find semi-automated machines more cost-effective, providing flexibility and control without excessive upfront investment.

-

Material Compatibility: The selected machine must be compatible with the necessary wrapping materials. For steel wire coils, durable materials like stretch film or protective wraps are often essential to prevent corrosion and mechanical damage. Ensuring material compatibility prevents material waste and maximizes protective coverage for each coil.

Automation in Coil Wrapping Machines: Enhancing Productivity

Automation in coil wrapping machines allows for faster, more consistent wrapping with minimal human oversight. Automated machines are equipped with programmable settings, allowing companies to set parameters such as wrap tension, material type, and coil size for consistent results across large batches. This reduces human error, speeds up production, and allows for accurate, uniform wrapping on every coil, thus greatly improving overall productivity and reducing waste.

Popular Brands and Models for Steel Wire Coil Wrapping

There are several leading manufacturers known for high-quality, reliable coil wrapping machines. Brands like FHOPEPACK, ROMM, Signode, and SHJLPACK offer machines with varying features tailored for steel wire coils, ranging from compact, semi-automatic models to fully automated systems with advanced sensors and programmable controls. Each model presents its own set of advantages and considerations based on machine footprint, energy consumption, and level of automation.

FAQs

-

How does a coil wrapping machine differ for steel vs. other materials?

-

Steel wire coils require extra protection due to their weight and potential for corrosion, making specialized wrapping essential.

-

What materials are used for wrapping steel wire coils?

-

Common materials include stretch films, polyethylene, and shrink wraps, chosen for durability and weather resistance.

-

Can coil wrapping machines handle different coil sizes?

-

Yes, most machines offer adjustable settings and components to accommodate a range of coil sizes.

-

Are coil wrapping machines suitable for other types of metals?

-

Yes, coil wrapping machines can be used for other metal coils like aluminum or copper, provided they are configured accordingly.

-

How can companies ensure safe operation of these machines?

-

Ensuring safety involves regular maintenance, proper operator training, and following established safety protocols, including the use of PPE and understanding emergency procedures.