Automatic Coil Packing Line Manufactuer | Fhopepack

Automatic coil packing line can be used to pack copper coil, wire coil, steel coil and hose coil. We use different types of conveyors to connect the packing line with the production line for highest efficiency. No matter through stratch wrapping or shrink packing, our machines are able to reduce huge amount of labor cost and material waste, that's why the machinery has a fast return on investment.

Automatic Coil Packing Line

-

Steel Coil Packaging lineAutomatic steel coil packaging system/strip coil packaging line is designed for the steel industry and is available at Fhope in China. This packaging line features a turnstile, coil upender, wrapping machine, and more, providing businesses with an all-in-one solution for their automatic slitted coil packaging needs. ...

-

Vertical coil packaging lineAutomatic steel coil packaging system/metal coil packaging line is designed for the steel industry and is available at Fhope in China. This packaging line features a turnstile, coil upender, wrapping machine, and more, providing businesses with an all-in-one solution for their automatic slitted coil packaging needs. With advanced...

-

Hose Coil Packaging lineAt Fhope, we offer a range of automatic hose coil packaging solutions, including hose coiling machines for HDPE pipes and corrugated coil packaging machines from coiling to stacking. Our comprehensive packaging line is designed to streamline the packaging process and increase productivity, providing businesses with a cost-effecti...

-

Copper Coil Packaging lineAutomatic wire coil packaging line is designed for the wire industry worldwide and features a film and paper automatic cutting and feeding system. This special coil wrapping machine is designed with a conveyor, providing businesses with a comprehensive and efficient solution for their wire coil packaging needs. With advanced feat...

-

Wire Coil Packaging lineAutomatic wire coil packaging line is designed for the wire industry around the world, featuring a film and paper automatic cutting and feeding system. This special coil wrapping machine is designed with a conveyor, providing businesses with a comprehensive and efficient solution for their wire coil packaging needs. With its adva...

-

Stainless steel coil packing lineThis copper coil stacking machinery is composed of turnstile, coil separator, weighing device, strapping machine, stacking system, conveyor line and etc. It can be used for separating, strapping, stacking and weighing of copper coils of width 10mm~300mm. This machinery is controlled by a supervisory control system, and each par...

-

Slit coil handling and packaging lineThe slit coil handling and packaging line includes strapping machines for coil tail and position coil spacer handling, providing businesses with a comprehensive solution for their coil packaging needs. This line also includes packing and stacking components, streamlining the packaging process and increasing productivity. With its...

-

Coil packing and storage lineAt our company, we offer a range of solutions for handling, strapping, and packaging cold roll steel coils. Our comprehensive solutions include roll blocks, roll cradles, packing machines, eye-through wrapping stations, and more, providing businesses with an all-in-one solution for their packaging needs. With our advanced feature...

-

Slitting steel coil packing line | Economic VersionEconomic type coil packaging line is a cost-effective solution for businesses seeking to streamline their packaging processes. This line includes a collection trolley, feeding-in passing tunnel, vertical packaging machine, feeding-out passing tunnel, stacking turnover machine, storage conveyor, and more, providing businesses with...

-

Steel Coil strapping & packing line | For Cold roll steelAutomatic cold roll steel coil packaging system provides a comprehensive solution for businesses seeking to streamline their packaging processes and reduce labor costs. This system includes automatic coil strapping, film wrapping, paper covering, edge protection, and a storage and handling system, providing businesses with an all...

-

Automatic Slit Coil Packaging SystemThe automaitc slitting coil handling system include: Turnstile, coil down ennder, coil turntable for strapping and coil stacking machine. It is able pick up the coil and turning 90 degree for chaning ID to wall into ID to sky. So that it is easy stacking coiling on pallet by automatic stacker one by one....

-

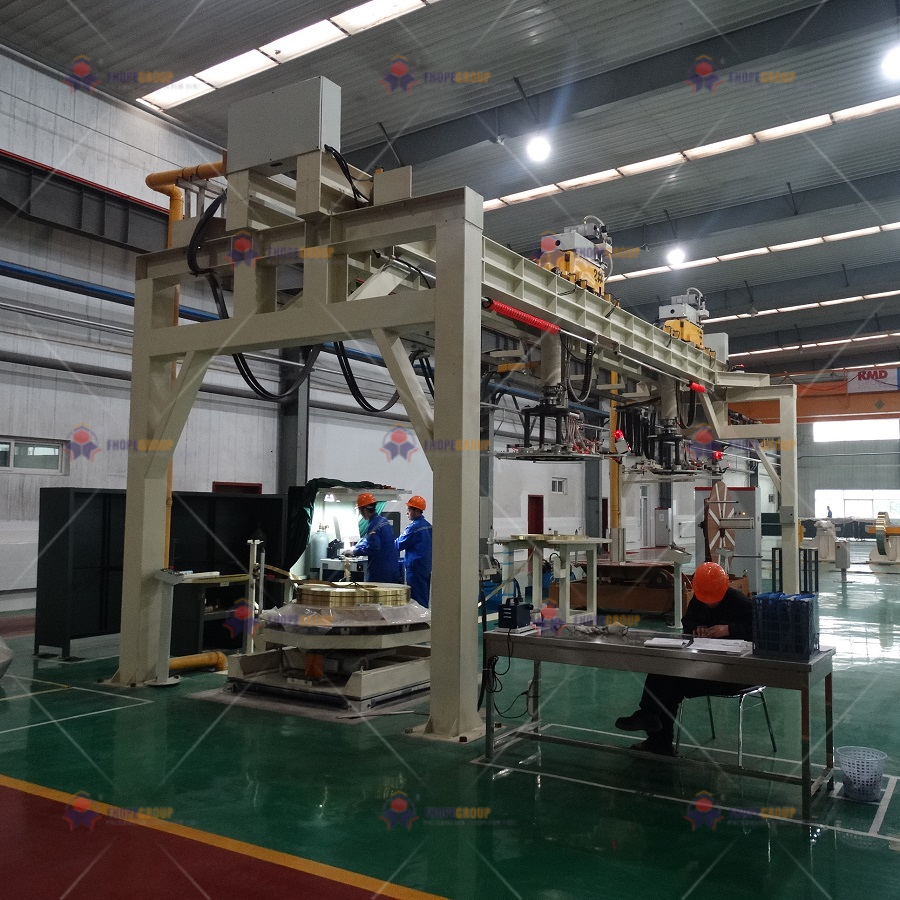

Brass copper strip vacuum handling and welding lineWelding lines are industrial equipment used to efficiently and consistently weld multiple copper coils together. This process minimizes manual handling and ensures high-quality welding. The exterior joint of the coil is welded on a rotating platform, while the interior joint is welded on a transit platform. A vacuum chuck is used...

-

Automatic slitting coil packaging line with turntable stackerAfter the contract becomes effective, the project schedule includes planning the workshop area, arranging the line layout, preparing foundation loading data and bolt plans, manufacturing mechanical & electrical equipment, instrumentation, automatic & hydraulic equipment, transporting, erecting & trial testing the equipment, commi...

-

PPGI Coils Packaging lineThis coil packing system is an ideal for industries requiring reliable packaging of steel coils for transport and storage, ensuring that the coils remain stable, secure, and protected from external damage during logistics handling....

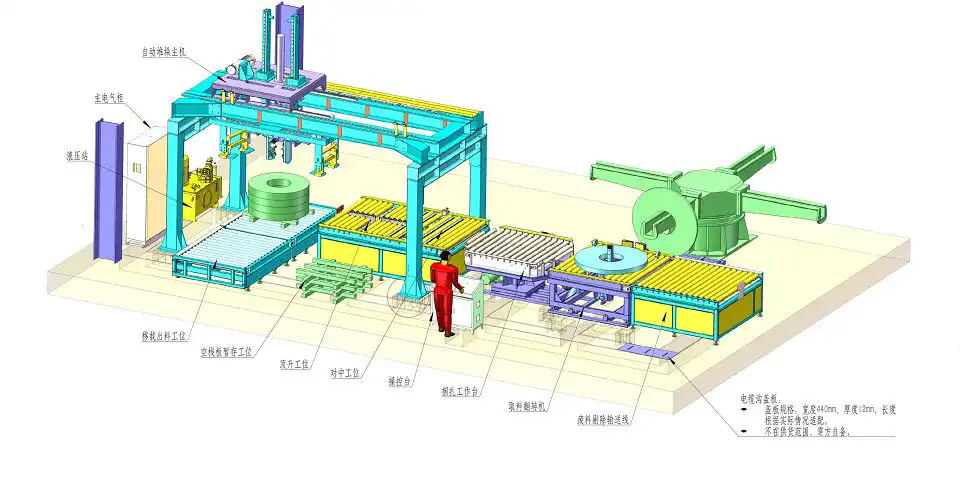

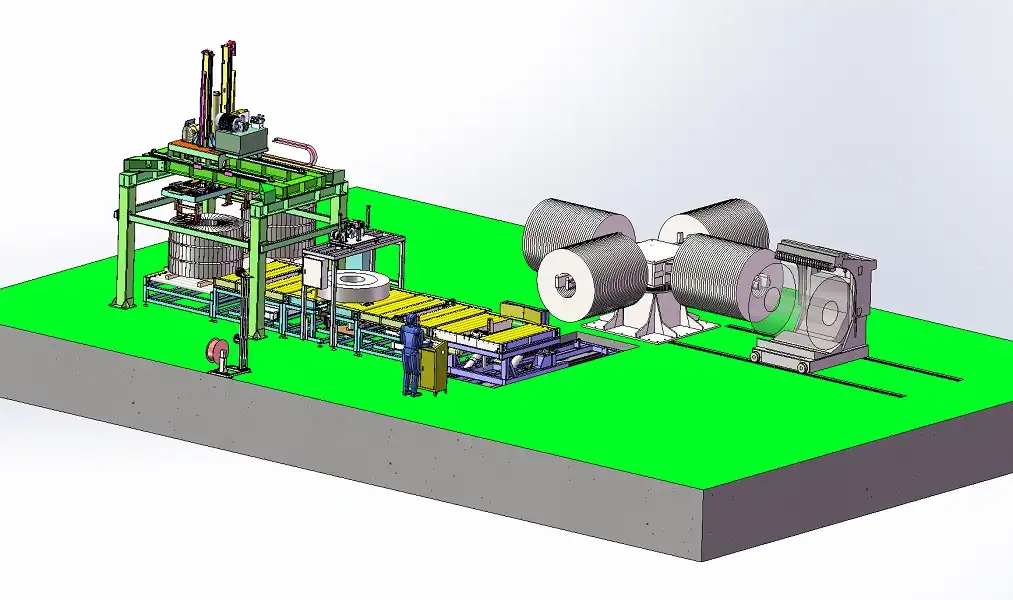

1. Automatic slit coil handling line

It is a groundbreaking solution designed for efficient and safe handling of heavy steel coils. This system streamlines the process of picking up coils from the slitting line using a coil car, sequentially retrieving them from a turnstile, and expertly stacking them.

- Coil car integration: Facilitates seamless coil transportation from the slitting line, enhancing efficiency.

- Coil Turnstile: Enables organized and sequential retrieval of coils, optimizing workflow.

- Coil stacking machine: Ensures precise and secure stacking of heavy steel coils.

- Enhanced safety: Reduces risks associated with manual handling and increases overall workplace safety.

Feel free contact us at any time.

2. Automatic Slit Coil Packing Line

The solution designed to streamline the packaging process for slit coils. Seamlessly connected to the slitting line, this advanced system automates packing, label printing, and more, ensuring efficient and precise coil packaging. Integrated with an ERP/MES system, the packing line also provides a robust database to support inventory management and data tracking.

- Seamless integration: Connects effortlessly with the slitting line for a smooth and efficient workflow.

- Steel coil wrapping machine: Provides precise and consistent packing by paper, stretch film... enhancing the overall packaging quality.

-

Coil strapping machine: Provides PET, steel belt stapping from semiauo to automatic coil or coil pallet strapping for transporation protection.

- Label printing: Automates label generation, ensuring accurate product identification and tracking.

- ERP/MES system compatibility: Facilitates seamless data sharing and inventory management for improved decision-making.

Feel free contact us at any time.

WHY CHOOSE FHOPE FOR COIL PACKING SYSTEM

- Safety: FHOPE packing line prioritize user safety with built-in CE protective features..

- Uptime: Our packing line solutions adapt to any load and speed, ensuring continuous, jam-free operation..

- Easy to use: user-friendly, requiring minimal training and maintenance, and consistently delivers quality and efficiency.

- Performance: leads the industry with 15+ years of innovative, updateing technology for coil packing.

- 24/7 support:unparalleled 24/7 support and service, best-in-class warranty.

- Automation: Programing and system connection from Level 1, level 2, level 3.

The idea of the slit coil packing modernization for service center is a plan for integrating coil packing equipements into the slit coil production plant. In the coil packing automation, there are machine embeds compact layers of packing materials over the entire surfaces of the coil. There are machines for picking up and moving the coil easily. There are packing material applicator keeps away maximum of the air from the package. There are solution to link with your production line line and storehouse for automatic running, strapping, wrapping and loading on pallets. The automation provided by FHOPE make only one man required to operate the whole line in secured way.

Solution of the coil packing line information: https://www.fhopepack.com/Automatic_Coil_packing_machinery.html

WHAT IS THE PROCEDURE OF THE COIL PACKING LINE PROJECT

- Solution discussion: Project discussion base on the customer's specification and packing function requirement. For all part of the packing line both in mechenical and electrical.

- Design and Engineering: All part of the packing line designing by 1:1 scale per 3D. Includes simulation to define load capacity, machine space, layout... utilizing CAD and FEA for production drawing.

- Material Selection: High-grade materail in steel, rubber, plastic...chosen for the structure for durability; durable gear, beraing, cylinder, air system, hydraulic system are based on operational requirements.

- Component Fabrication: Precision CNC machines carefully craft and structurally weld each part, followed by meticulous grinding and polishing, ensuring each component fits perfectly and functions optimally in our coil packing lines.

- Further Processing: Components undergo quenching, straightening, galvanizing, and rubber coating, painting, enhancing durability and performance .

- Assembly: Components are assembled meticulously, integrating necessary hydraulic or electrical systems, with a thorough check of all connections.

- Testing: Comprehensive load testing all machines for confirms the packing line's capacity per designing in packing speed, safety, operation.

- Program debuging: coil packing simulation per handling, loading and actual operation for fine tuning and debuging

- Finishing: A protective coating is applied to resist rust and wear, painting recover, cable and air tubing numering checking.

- Quality Control & Delivery: Continuous quality assessments during production, with a final inspection pre-delivery. Machines are shipped partially disassembled for ease of transport and installation.

Frequently Asked Questions

We've compiled key FAQs about coil packing lin projects for your convenience. If you don't find your question, call us at +8613951501635 or email info@fhopepack.com.

> What's The Warranty Period?

> Do You Provide The Local Installation?

> What types of coils can the packing line handle?

> How do I adjust the packing line for different coil sizes?

> What is the safety system?

More info: LOTO Safety System For The Packing Machine

> What About The After Service?

> What is the coil packing speed?

> Can packing line be Customized according our requirement?

> Can the coil packing line be integrated with other production line equipment?

> Can you provide the turnkey solution for the whole service center?

Download

|

|

|

|

| FPH-200 | FPH-300 | FPH-400 |

|

More Article relates to the coil packing line:

1. Rolled Coil Automatic Packing Line Basic Specification.

2. How to do numbering for the coil packing line project?

3. How to do visual management for the coil packing line project?

4. Why Automatic Steel Coil Palletizing Is Safer Than Palletizing Manually By Hand?

5. Top 6 things To Consider When Purchasing A Steel Coil Packing Line

SHOWCASE & NEWS

Product Inquiry

Our team will reply in 24 hours

![]() Email: info@fhopepack.com

Email: info@fhopepack.com

![]() Whatsapp: 0086-13951501635

Whatsapp: 0086-13951501635