Problems Facing the Customer's Factory

Operation Safety

At the customer’s factory, steel coils are often handled manually using cranes to move them from one position to another. This method not only increases the risk of workplace accidents but also makes the entire process inefficient. Moreover, wrapping is done manually, leading to potential inconsistencies in packaging quality and exposing workers to further safety hazards.

Product Quality Recall

One of the major challenges faced by the customer is tracking issues in the production process, which leads to frequent product recalls. Without a proper system to log and monitor coil production data, identifying which coil has issues becomes difficult. This results in repetitive recalls of products from the same production batch, leading to time and financial losses.

Efficiency & Labor Shortage

Labor shortages are a common issue at the factory, significantly impacting production efficiency. Relying on manual operations for handling and packaging the coils leads to slower production rates, higher labor costs, and increased operational delays. Automation is crucial to improve workflow and reduce dependency on manual labor.

Solutions to the Challenges

a. Turnstile

The turnstile with multiple arms enhances coil handling by allowing coils to be loaded and stored efficiently without the need for constant crane operation. This mechanism allows for seamless movement and rotation of coils, improving both the workflow and the safety of operations. It also reduces manual labor and the frequency of human intervention, making the coil packing process smoother and faster. Its sturdy design ensures that heavy coils are safely positioned, minimizing the risk of accidents.

b. Down Ender

The down ender is a crucial piece of equipment for rotating coils from a horizontal to vertical position (or vice versa) in preparation for further processing. This machine ensures that coils are moved without manual lifting, enhancing worker safety and reducing the risk of coil damage. Its hydraulic system offers precise control during lifting and rotating, allowing for consistent handling of coils of varying sizes and weights, from 100 kg to 4000 kg. By automating this process, it improves efficiency and operational safety.

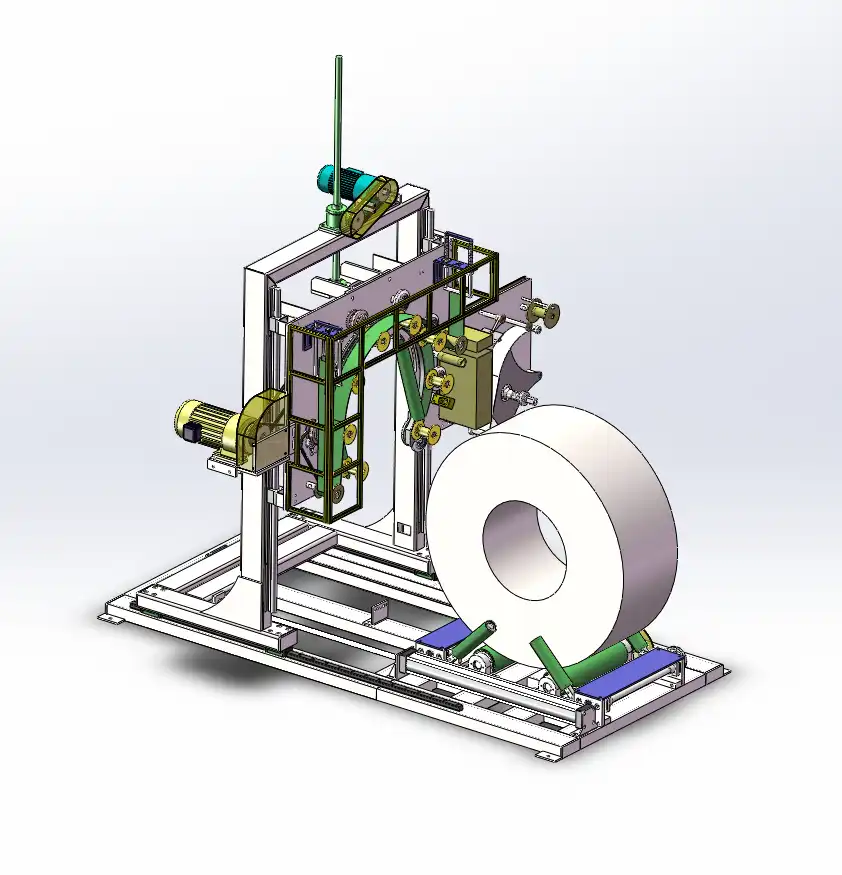

c. Coil Wrapping Machine

The coil wrapping machine automates the process of securely packaging steel coils. This machine wraps the coils using materials like stretch film or paper, ensuring consistent protection of the product during handling and transport. By adjusting wrapping tension and speed, it guarantees that each coil is properly protected from external damage. Additionally, this automation reduces labor costs and increases packaging speed, allowing factories to meet higher production demands with consistent quality.

d. Coil Stacking Machine

This machine automates the stacking of wrapped coils onto pallets, removing the need for manual intervention. It uses hydraulic lifting and vacuum technology to lift and place the coils precisely on the pallet, reducing the risk of injury to workers. This also ensures that coils are stacked uniformly, preventing damage during storage or transportation. The automation streamlines the packaging process, helping to manage high volumes of coils efficiently.

e. Printer

The printer is integrated into the coil packing line to print essential labels that include details such as coil dimensions, weight, and production batch numbers. This information is crucial for tracking each coil throughout the supply chain. Proper labeling improves the traceability of coils and helps prevent issues related to product recalls. The printer’s integration ensures that each coil is properly marked, enhancing the efficiency of inventory management and reducing errors.

f. Control System with ERP Connection

The control system linked with ERP software tracks the entire production process in real time. It collects and logs data such as coil dimensions, weight, production times, and batch information. This integration allows for seamless tracking of each coil, from production through shipping. The system enables quick identification of any defects or issues, reducing product recalls and improving quality control. Having this data readily available improves decision-making and operational transparency.

Final Result

The customer is highly satisfied with the new automated coil packing line. It has improved safety, minimized product recalls through better tracking, and enhanced overall efficiency despite the labor shortage. Automation has drastically reduced operational risks and increased productivity, leading to a happier and more efficient workforce.

Specifications:

-

-

Outer Diameter (OD): 800-1600mm

-

Inner Diameter (ID): 508mm

-

Width: 30-400mm

-

Weight: 100-4000kg

-

Maximum Coil Stacking Weight: 6000 kg per pallet

-

Maximum packing speed: 20-35coils per hour, Ensures compatibility with a wide range of coil packing speed.

-

Wrapping Speed: Up to 70 rpm: High-speed operation to match industrial production rates.

-

Control System: Advanced PLC with HMI touchscreen: Provides precise control and easy adjustments.

-

Voltage Requirement: 240/480 V, 50/60 Hz, 3 Phase: Adaptable to different power supplies across the USA.

More coil packing line information>