Home > Products > Show Room > Coil Packing Line >

Fhopepack Innovation

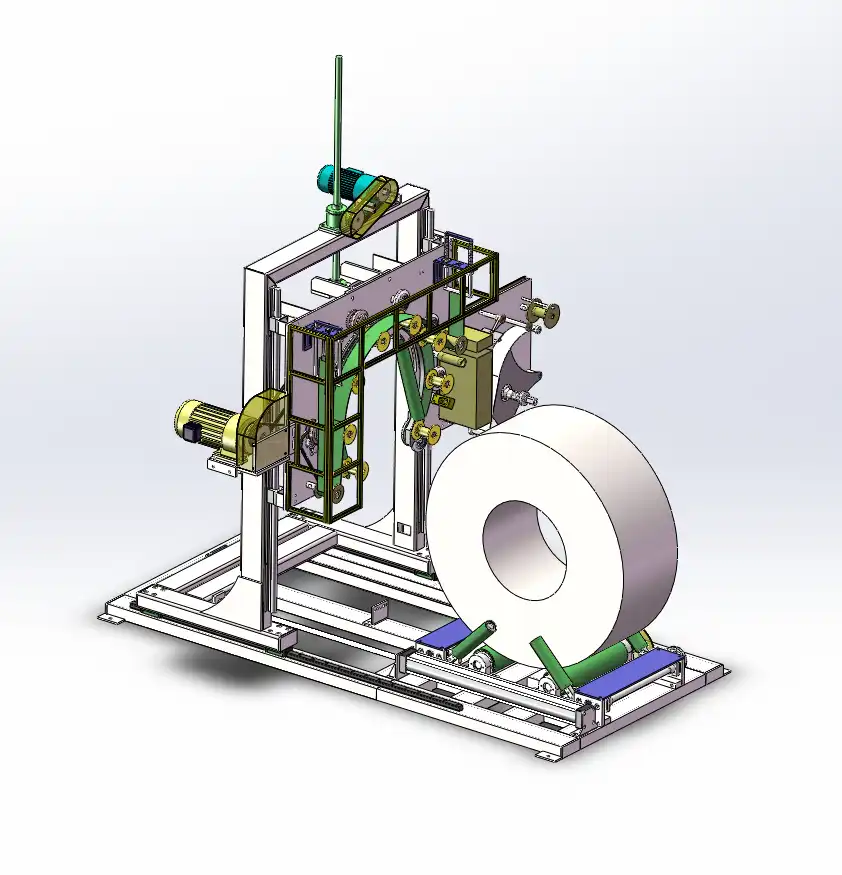

Top 5 Things to Consider when Purchasing a Packing Solution For Steel Coil Slitting Line

When selecting a packing system, assess overall line output requirements and coil specifications handled. Consider machinery construction quality, seeking heavy-gauge steel that stands up to nonstop operation. Evaluate safety mechanisms and accessibility for maintenance. Ensure control software integration and material flexibility suit production needs.