Automatic coil packing solution – The way to improve your coil packing from manually to automatically

The steel coil is a heavy load that is not easy to handle manually. For safety and more efficient coil packing, many factories are looking for a solution to resolve the problems caused by coil status. FHOPE provides a coil packing system that designs according to your packing requirements. There are different types of packing lines to connect the slitting line with coil downender, crane, forklift... We provide a hot mill coil packing system too for achieving the highest efficiency. No matter coil information scanning, strapping, or packing, our system is able to reduce a huge amount of labor costs by using a flexible system for handling and stacking. And we provide the solution to help you achieve a fast return on investment.

Benefits of automatic slitting coil packing line

1. Efficiency handling, packaging, palletizin...that works for different coil specification.

2. Trackable in all steps and connectable with ERP system from packing to stocking.

3. Better packaging in coil surface, strapping and palletizing.

4. Safety operation.

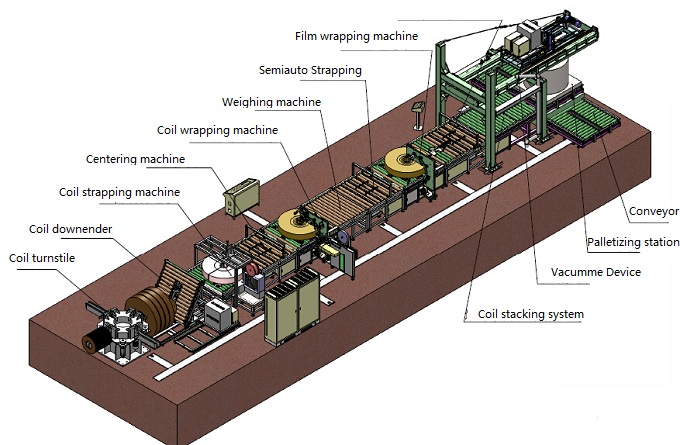

A. SLIT COIL HANDLING AND STACKING LINE

Automatic slitting coil packing line: automatic coil handling,stacking and palletizing system for moving the slitted coil from slitting line to the pallet and move to the warehouse. Depands on the packaging goal, the wrapping and strapping machine is an option that Min. the automatic coil handling packing line in cost.

The solution is for making the coil handling and packing in a stream line

The handling solution is mainly for picking up the coil from coil car, and moves the coil into stacking machine to replce the crane or forklifter. The key station is the coil stacking machine that is for stacking the coil one by one on pallet. That is more easy and safety that another handling ways.

B. SLIT COIL WRAPPING AND STACKING LINE

The concept of a packing line is an essential element in coil packing machinery, designed to meticulously wrap coils with multiple layers of protective materials. This method ensures very tight coverage, limiting the amount of air trapped within the package. By minimizing air exposure, the machine significantly reduces the risk of moisture accumulation, which is crucial for preventing corrosion and water spots on the coil.

Advanced features of the machinery, such as automated control systems, enable precise application of packing materials, ensuring consistent quality and protection. The materials chosen—typically plastics, foils, or treated papers—are selected for their durability and moisture-resistant qualities, further enhancing the coil's safety during storage and transport.

Automatic slitting coils packing solution with prefect ROI

FHOPE providing customized coil packing system that designs according different packaging goal and buddet level. The packing system just need 1-2 man for all operation steps. Accourding to the handling way the packing line can be diesigned with coil car feeding, crane loading, even forklifter in&out.

|

Handling speed: |

70-120 sec per coil. |

|

Max.coil Weight: |

6T |

|

Strapping: |

By PET/STEEL |

|

Packing material: |

Per requirement |

|

Control level: |

Level 1-3 |

|

Iot: |

Yes |

|

Compiticable with: |

MES, ERP |

|

Space: |

per fa8ctory Layout |

C. SLITTING COIL PACKING AND STACKING LINE

A second layer of packing material is then applied according requirement. The second layer of packing material holds the ancillary package in place and more protects the inner airtight layer of film. The outer layer shall be torn from handling damage. Besides the inner layer remains intact and thus the coil stays sealed and protected, because of the ancillary material is in between which is applied separately by the two layers

From Automatic coil packaging line, through coil wrapping machines to relating packaging materials, Fhope offers a wide variety of packaging equipments that covers a broad range for coil object.

Browse our entire range of solutions by selecting the areas that are right for you.

The typical requirement in the slitting coil packaging

D. COLD ROLL COIL HANDLING AND PACKAGING LINE

The ancillary packing in cold roll coil packaging systems offers enhanced protection through components such as outside diameter protectors, inside diameter protectors, side wall protectors, and belly wrap materials. These protectors are crucial for safeguarding sensitive areas of the coil that are prone to damage during handling, transportation, or storage. Depending on the specific requirements of the packaging line, these protective materials can be integrated into an automated system for consistent and efficient application or applied manually for customized protection needs.

The solution is for making the coil handling and packing in a stream line

In addition to providing robust physical protection, these ancillary materials are typically made from recyclable plastics, supporting environmental sustainability. By choosing materials that can be recycled, the packaging process not only secures the coil against physical and environmental damage but also aligns with eco-friendly practices. This approach helps reduce waste and supports a circular economy, making it an ideal solution for industries aiming to minimize their environmental impact while maintaining high standards of coil protection.

The typical packaging way of the cold roll steel coil packaging

|

1. ID hole protector |

2. ID steel edge protector |

3. OD steel edge protector |

|

4. OD edge protector strapping |

5. ID cardboard protector |

6.OD cardboard protector |

| 7.Cold roll steel coil OD strapping | 8.VCI paper covering | 9.VCI film stretch wrapping |

| 10.Cardboard OD covering | 11.Steel sheet OD covering | 12.Side cover |

| 13.OD Edge protector | 14.Cercumferece coil strapping |

15.Radial coil strapping |

There are solution to connect with your slitting line and warehouse for automatic handling, strapping, wrapping and stacking on pallets. Only one man is able operating the whole line in safety way.

.jpg)

Coil strapping machine Coil pallet stacker

The speed of ring and rollers are adjustable to accommodate materials varying in thickness. The conveyor belt or supportive roller can be raised or lowered and in some models, even tilted to the desired angle for packing. It can be equipped with an ink coding system , or an imprinter to record words, dates, and codes with each seal for each products.

Speed of Automatic coil packing machinery are considerably faster much more than by manually , it is ideal equipment for projects which require minimal space and costs and higher production rates.

By machine - Automatic coil wrapping machinery or Coil Packing Machine

Find the right solution to fit your needs by selecting the type of machine you are interested in.

By industry--Find the right solution to your packaging needs by selecting your industry/market segment.

More coil packaging information

Related coil packing line video

Coil Packing Line

-

Automatic copper slitting coil strip packaging lineAutomatic copper slitting coil strip packaging line is specifically designed to package copper coils with care and precision. These coils are often bundled in large copper sheet coils and tightly coiled into smaller lengths once they are cut and slit. Our state-of-the-art technology streamlines the entire packaging process, ensur...

-

What Is The Capacity of The Coil Packing LineCoil Packing Line Sizes The coil packing line is available in a range of sizes to cater to various packaging needs. The line offers adjustable parameters that can be tailored to accommodate different dimensions and specifications. These adjustable parameters include: Coil Weight: The packing line can handle coils of varying weigh...

-

What Is The Way To Know Coil packing line price By YourselfOur team of experts works closely with clients to assess their packaging requirements, taking into account factors such as coil size, throughput, automation needs, and environmental considerations. Based on these detailed assessments, we are able to design and engineer bespoke packing line solutions that meet the exact needs of t...

-

What Is The Technical The Best Coil Packing Line Should IncluDiscover the optimal solution for your slit coil packaging needs with our best coil packing line. Engineered for efficiency, our machines streamline the wrapping process, ensuring secure, durable protection for coils against moisture and damage. Ideal for service center and steel industries requiring precise handling and robust p...

-

What is Crucial in Steel Coil Packaging Line IntegrationsCoil packing line manufacturers Fhope is a specialized manufacturer of coil packaging machinery. We offer a comprehensive range of coil wrapping machines, coil strapping systems, and coil tilter solutions that cater to the specific needs of coil packing , including steel coil packing line. We provide custom-built coil packaging s...

-

What after service you will have for Copper strip packing linTo ensure efficient operation and reliability of your copper strip packing line, we provide customized service contracts, proactive spare parts management, and ongoing communication about equipment updates. We also offer integration services for new materials and optimization strategies to reduce material use without compromising...

-

What Is The Technical Efficiency for Slit Coil Packaging SystThese advanced systems are designed to seamlessly integrate automation and mechanization throughout the entire packaging process, ensuring maximum efficiency and productivity. At the heart of our Slit Coil Packaging Systems is a fully automated material handling system that effortlessly transports and positions the coils....

-

How to measure the technical efficiency for steel coil strappThe way to measure technical efficiency for steel coil strapping line that designed to streamline processes, minimize downtime, and optimize productivity in the steel industry. And it designed to securely fasten steel coils for transportation and storage purposes. The strapping lines that ensure the safe handling and protection o...

-

Guide to Optimizing Operational Expenditures For Steel Coil SThe Steel Coil Strapping and Stacking Line is engineered for efficient handling and secure packaging of steel coils. This automated line ensures precision in strapping and optimal stacking for safe transportation and storage, enhancing operational throughput and reducing labor costs....

-

Solutions for Optimizing OpEx in Steel Coil Packing And StrapImplementing preventative maintenance and remote diagnostic systems can significantly reduce downtime and repair costs for coil packaging lines. Strategies like incorporating modular servo-driven components with integrated sensors allow easier accessibility and quick condition monitoring. ...

-

Which is Best Palletizing for Your Steel Coil Palletizing LinWhen choosing a palletizing approach, factors like production volumes, coil sizes and stacking heights must be considered. Turntable systems excel at random patterns but cantilevered robots palletize continuously at high rates. Wrap-rolling performs single-coil wrapping efficiently while stackers consolidate into tiers. Assessing...

-

Top 5 Things to Consider when Purchasing a Packing Solution FWhen selecting a packing system, assess overall line output requirements and coil specifications handled. Consider machinery construction quality, seeking heavy-gauge steel that stands up to nonstop operation. Evaluate safety mechanisms and accessibility for maintenance. Ensure control software integration and material flexibilit...

-

Showcase: Coil Packing Line In USAThis is the Coil Packing Line designed for USA customer that was designed to enhance the safety and speed of coil packaging operations. It integrates cutting-edge automation technologies to ensure precise and secure wrapping, thereby optimizing productivity and reducing material waste in American manufacturing sectors....

-

Metal Coil Strapping And Packing Line In ColombiaThe metal Coil strapping and Packing Line in Colombia is an advanced, automated solution designed to efficiently wrap and protect metal coils. It ensures high-quality packaging with precision and speed, reducing labor costs and enhancing safety in industrial settings. Ideal for the dynamic needs of Colombian markets....

-

Packaging Line Of Metal Rolls And CoilsThe Packaging Line of Metal Rolls and Coils optimizes efficiency in industrial settings. This automated system securely wraps rolls and coils, ensuring safe transport and storage. Durable and adaptable, it integrates smoothly with existing lines, significantly boosting productivity and reducing operational costs....

-

How to prevent coils being picked up missed together in coil The Prevent Multiple Coils from Being Picked Up Simultaneously or Missed Altogether The function of a downender in a steel coil packaging line is to rotate and position steel coils for further processing or packaging. Specifically, it picks up the coil and rotates it 90 degrees, typically turning the coil from a vertical "eye-to-...

-

Guide of the Coil Car for Integrating the Coil Rewinder with This article provides a comprehensive guide on using a coil car to integrate the coil rewinder with the coil packing line. It covers essential procedures, safety measures, and technical specifications to ensure seamless operation. By following these guidelines, manufacturers can enhance efficiency, reduce downtime, and maintain h...

-

Turnkey Solution: Fully Automated Coil Slitting and Packing LThis project showcases a comprehensive turnkey solution featuring a fully automated production and packaging line, which integrates both a high-efficiency slitting line and an advanced coil packing line. This system is designed to enhance operational efficiency, reduce labor costs, and ensure product integrity throughout the manu...

-

Automated Coil Strapping and Packing Line: Boost Efficiency aSolving Common Coil Strapping and Packing Challenges: A Comprehensive Solution for Steel Service Centers For many steel service centers, such as those in Brasilia, Brazil , the process of handling and packaging steel coils can be time-consuming, labor-intensive, and prone to inconsistencies. Manual strapping and packing after coi...

-

Top Coil Wrapping Line ManufacturerDiscover the leading coil wrapping line manufacturer offering innovative solutions for efficient and secure coil packaging. With advanced technology, customizable features, and a commitment to quality, these manufacturers help industries enhance productivity while reducing costs. Whether for steel, aluminum, or other materials, t...

-

Semi-Automatic and Fully Automatic Steel Coil Packing Lines DThe Differences Between Semi-Automatic and Fully Automatic Steel Coil Packing Lines As industries like automotive , construction , and manufacturing continue to evolve, steel coil packaging systems are becoming an essential part of the supply chain. Whether you are handling large steel coils for heavy machinery or smaller coils f...

-

How to Get the Most Out of Your Steel Coil Packing Line ThrouMaximizing the performance of your steel coil packing line starts with proper training. This article delves into effective training techniques, covering hands-on practice, continuous learning, and tailored programs for different roles, all aimed at boosting efficiency, reducing downtime, and ensuring the safe operation of your eq...

-

The Importance of Equipment Testing and Commissioning for SteEquipment testing and commissioning are vital steps in ensuring the smooth operation of steel coil packing lines. This article explores how these processes help prevent costly breakdowns, enhance safety, improve packaging quality, and extend the lifespan of the machinery, ultimately leading to increased efficiency and productivit...

-

How Our Installation and Support Services Ensure Minimal DownOur installation and support services ensure minimal downtime for your steel coil packing line by providing precise equipment setup, comprehensive maintenance plans, and continuous monitoring. We also offer customized training programs, empowering your team to operate efficiently and handle minor issues, ultimately boosting produ...

-

Understanding the Pricing Structure for Steel Coil Packing LiUnderstanding the pricing structure for steel coil packing lines requires a comprehensive look at factors like machinery type, automation levels, customization, and long-term operating costs. This article breaks down these elements, offering insights to help businesses make informed investment decisions while optimizing operation...

-

How We Provide Fast Solutions to Minimize Downtime for Steel Our fast solutions for steel coil packing lines focus on minimizing downtime through prompt troubleshooting, expert support, and immediate access to essential spare parts. We help companies avoid extended delays, keeping production lines running smoothly and efficiently with minimal interruptions....

-

Lessons Learned: Best Practices from Successful Steel Coil PaDiscover the key takeaways from successful steel coil packing line projects, highlighting best practices that improve productivity and safety. This article covers essential strategies, from selecting the right equipment to streamlining processes, ensuring long-term benefits for manufacturers looking to optimize their packaging op...

By machine - Automatic slitting coil wrapping machinery or Coil Packing Machine Find the right solution to fit your needs by selecting the type of machine you are interested in.

By industry--Find the right solution to your packaging needs by selecting your industry/market segment. More coil packaging information

Reference:

To find more coil packing line information: https://www.fhopepack.com/coil-packing-line.html

Powerful Coil Packing Line At Your Fingertips

Automatic Coil Packing Line Manufactuer | Fhopepack

SHOWCASE & NEWS

Product Inquiry

Our team will reply in 24 hours

![]() Email: [email protected]

Email: [email protected]

![]() Whatsapp: 0086-13951501635

Whatsapp: 0086-13951501635