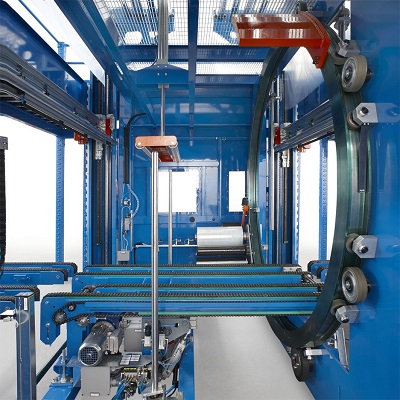

As a professional manufacturer of packaging machines for long-shaped items, Fhope has developed horizontal orbital wrapping machines and stretch wrappers for various straight objects. These machines have a successful track record across many industries, including packaging for profiled products, tubes, planks, steel pipes, aluminum sections, windows, doors, rods, and panels.

With over 15 years of experience, FHOPE offers machines that can wrap a wide range of products using stretch film, providing cost-effective packaging solutions.Our orbital stretch wrap machines are ideal for packaging large products, furniture, doors, windows, stacked plates, textiles, profiles, moldings, blinds, and tubes.

The stretch film ensures secure wrapping of stacked items and is more economical than shrink wrapping due to lower energy consumption and flexible reel sizes. These machines are designed to boost productivity and cut costs while using recyclable films, ensuring high-quality packaging for any company or industrial facility.

CONTACT US FOR THE SOLUTION

|

|

|

|

|

|

|

|

|

|

MORE MACHINE PER APPLICATION

|

|

|

|

|

Chapter One: |

Chapter Two:Aluminum Profile Packing Solution

|

Chapter Three:

|

Chapter Four: |

|

|

|

|

|

Chapter Five:

|

Chapter Six: |

Chapter Seven |

Chapter Eight:Others |

Safety is key when choosing a wrapping machine. It can help avoid accidents and injuries. Remember, injuries can make workers miss work and cost businesses a lot of money.

Risks for workers who wrap by hand include:

It should also be easy to use. Look for a simple control panel and clear displays. It should adjust to different package sizes and be easy to load with packing material. You should be able to make changes without complicated programming.

Key Features:

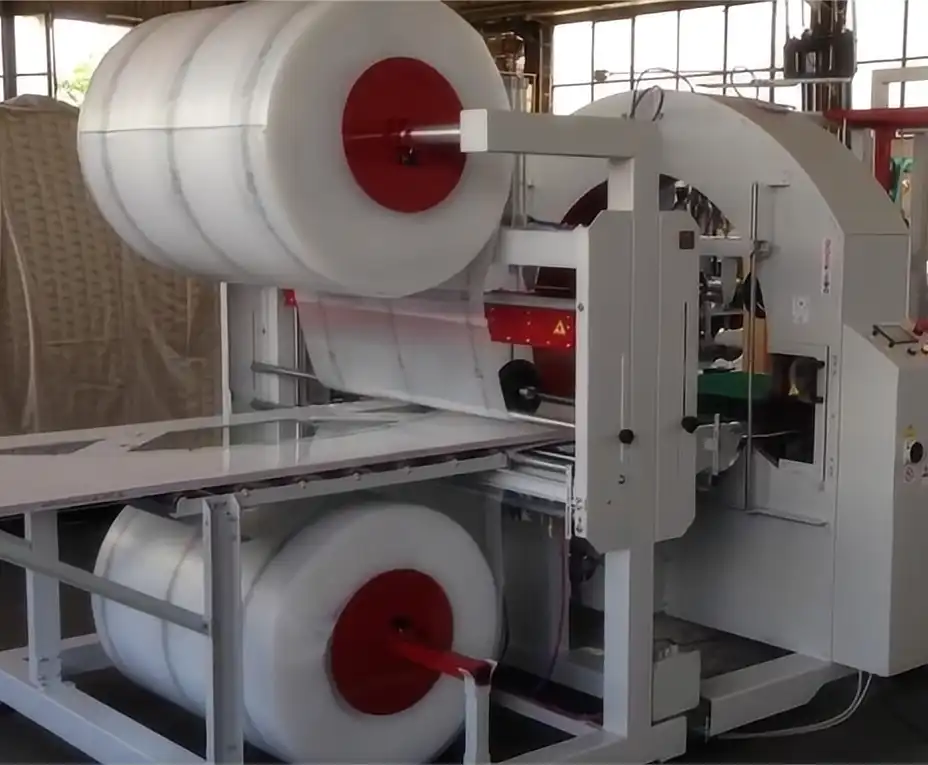

It's a a type of packaging machine that uses a vertical rotating ring to wrap products in a horizontal orientation. Normally the packing material would be stretch film,knit belt...

More info: https://www.fhopepack.com/blog/what-is-a-horizontal-orbital-stretch-wrapper/

It is commonly used to wrap long products or bundles of products such as pipes, plastic profiles, timber, extruded aluminum, board, panel and other long-length items. More info: https://www.fhopepack.com/blog/what-types-of-products-can-be-wrapped-with-orbital-wrapping-machine/.

The machine wraps stretch film around the product as it passes through a rotating ring. The stretch is controlled to ensure the film is tight enough to hold the items together.The number of layers and the amount of overlap can usually be adjusted to meet the requirements for the stability and protection of the load.

More info:How Does the Horizontal Orbital Stretch Wrapper Work?

Yes. The machine includes many models designed to accommodate a variety of dimensions and shapes. Each machine features adjustable settings that allow it to conform to the specific requirements of the product being wrapped. And we offer the option to customize the machinery as per the unique specifications of your products.

More info:Can the orbital wrapping Machine Be Integrated Into an Existing Production Line?

Yes, you can typically adjust the tension to ensure a tight wrap without damaging the product. More info for the wrapping tension control solution

An orbital stretch wrapper machine is versatile in the types of packing materials it can use, each offering unique benefits based on the product and industry requirements. Here’s a breakdown of common materials:

PE Film

Polyethylene (PE) film is widely used due to its durability and resistance to tearing. It's ideal for applications requiring a secure, moisture-resistant layer that keeps products protected from environmental factors like humidity. PE film is also cost-effective and often chosen for wrapping irregularly shaped or large items, providing a strong, consistent covering that shields against dust and dirt.

Stretch Film

Stretch film, often made from linear low-density polyethylene (LLDPE), is designed to be highly elastic, allowing it to cling tightly to products. Its stretchability provides a tight, secure wrap that keeps items in place, making it perfect for stability during transport. It’s also puncture-resistant, adding extra protection for fragile or stacked products. Stretch film is commonly used in industries where load stability is a priority.

Fabric

Fabric materials, such as woven or non-woven textiles, are excellent for wrapping delicate items that require a soft, protective layer. These fabrics can prevent scratches and are breathable, which reduces condensation on wrapped products. Common in sectors where surface protection is key, fabric wraps are reusable, offering a sustainable option for companies prioritizing eco-friendly packaging solutions.

Paper

Paper wrapping provides an eco-friendly and cost-effective solution for products that need basic protection. It’s often chosen for items requiring minimal protection, as it doesn’t offer the same strength as plastic-based films. Paper wrap is also lightweight and easily customizable, making it suitable for packaging that emphasizes sustainability and recyclability, without compromising product integrity.

Bubble Film

Bubble film, made from plastic with air-filled pockets, offers excellent cushioning and is ideal for fragile or sensitive items. The bubbles provide shock absorption, which prevents damage during handling and transportation. Bubble film is often layered around delicate products to ensure that vibrations and impacts are minimized, making it popular in industries where product integrity during shipping is a priority.

Each material serves specific purposes based on the product’s needs and the desired level of protection.

.

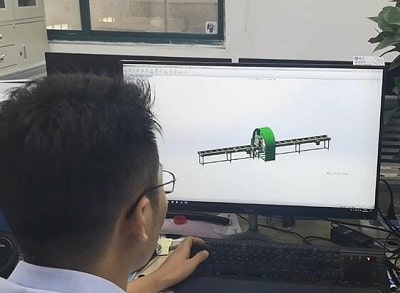

Yes, our machines are specifically engineered with integration capabilities to fit seamlessly into existing production lines. We offer customized solutions tailored to the unique specifications and layout of your current operation. Our team of professional engineers is adept at designing and configuring the machinery to work in concert with your established systems, ensuring a smooth and efficient transition.

The speed at which our machine can wrap products is contingent upon the size and characteristics of the items being packaged. Our machines are designed to maintain high efficiency across a spectrum of different product sizes.

Regular maintenance is relatively straightforward, focusing on keeping components clean and checking for wear.

Article: Tips for Installing and Maintaining a horizontal Wrapper

Yes, safety features typically include emergency stops, guards, and safety sensors.

The footprint varies by model. We typically provide detailed dimensions that facilitate effective space planning and aid in the layout design.

Yes, the machine is capable of wrapping irregularly shaped items. It can be customized to accommodate various shapes and sizes, making it suitable for a wide range of products. By providing detailed specifications and product requirements, the machine can be tailored accordingly to effectively handle and wrap items of diverse shapes.

Yes, the machine is designed to be user-friendly and easy to operate. It is engineered with intuitive controls and clear instructions, minimizing the learning curve associated with its operation. The user-friendly interface and ergonomic design facilitate a seamless user experience. The machine comes with manuals which serves as valuable resources, ensuring that operators have access to the necessary information to operate the machine effectively.

Power requirements vary, but details are typically provided in the machine's specifications.It can be customized as per customers’ requirement.

Many models offer automatic cut and seal features for a complete wrapping solution.

Consider your product dimensions, shape, produ