Door Shrinking Machine with Motion Sealer: Advanced Packaging Technology for the Modern Manufacturer

The Door Shrinking Machine with Motion Sealer is an advanced and cost-effective solution designed for efficient and professional door packaging. This machine not only delivers high-quality packaging but also integrates seamlessly into production lines, enabling fully automated processes. With its ability to handle various door sizes, this machine ensures precise, tight, and aesthetically pleasing packages, all while providing reliable protection during transit and storage.

Key Components and Features

The machine comprises two primary systems: the sealing unit and the shrinking tunnel. Both systems are powered by cutting-edge technology that guarantees efficient operation with minimal human intervention. Below are some of the key features that make this machine stand out:

Motion Sealer for Full-Sided Packaging:

1. The machine is equipped with a long sealer and two motion sealers, ensuring the door is fully wrapped and sealed on all sides.

2. The motion sealer provides smooth and clean sealing, ensuring the film sticks uniformly across the door surface, enhancing both protection and appearance.

Automatic Shrinking Process:

1. Once the door is sealed, it enters the shrinking tunnel, where hot air circulates around the package, shrinking the film tightly around the door.

2. This automatic process ensures that every package is consistent in quality, reducing labor costs and improving productivity.

Adjustable and Flexible Operations:

1. The machine can switch between automatic and manual feed modes, allowing operators to choose the mode that best fits their production requirements.

2. Adjustable sealing heights make it compatible with a wide range of door sizes, making it versatile for manufacturers handling different door specifications.

Precision and Safety:

1. The door shrinking machine features a photoelectric sensor for accurate product positioning during packaging, reducing errors and waste.

2. It is equipped with safety guardrails, and the system automatically detects and reports issues, ensuring smooth and safe operation.

High-Efficiency Shrinking Tunnel

The shrinking tunnel is the heart of the packaging process, designed with energy efficiency and precise control in mind:

-

Temperature Regulation: The temperature in the shrinking tunnel is adjustable between 100°C and 220°C, ensuring optimal shrinkage for different types of packaging films.

-

Heat Conservation: With an insulated recirculation heating system, the machine minimizes heat loss, resulting in lower energy consumption.

-

Cooling System: The machine features a rapid cooling system that cools the door immediately after shrinking, ensuring the film remains tight and secure without warping.

PLC-Controlled Automation

The machine is fully automated, controlled by a PLC system that manages the entire packaging process from film application to shrinking. The system is user-friendly, with a simple interface that allows operators to adjust settings, monitor the machine’s status, and respond to alarms quickly.

-

High Precision: The PLC ensures every step of the process is completed with high accuracy, from sealing to shrinking, minimizing errors.

-

Customizable Operation: The action time in each stage can be adjusted to match specific packaging requirements, making the system highly adaptable to various products.

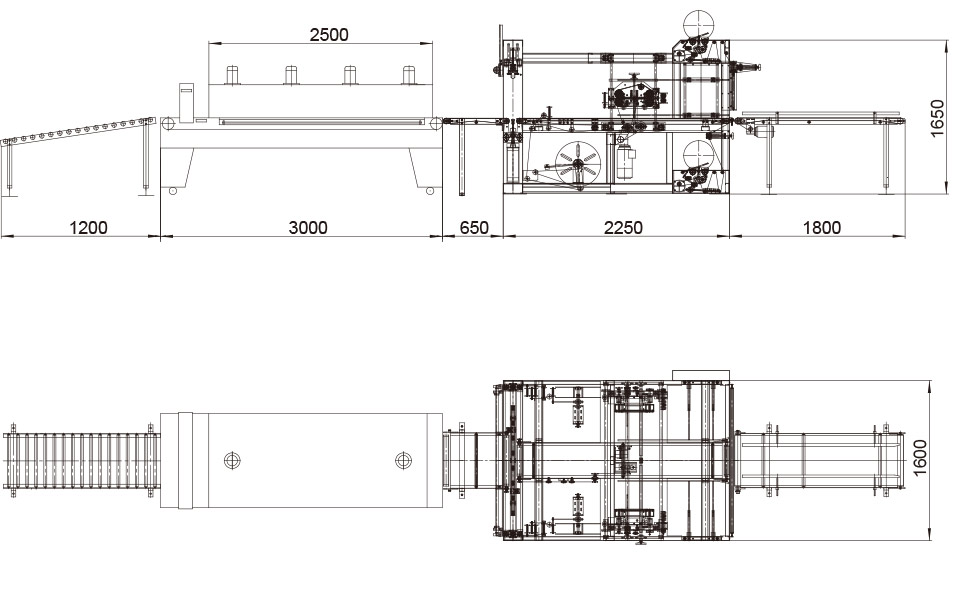

Technical Specifications

Here’s a brief overview of the technical specifications for the Door Shrinking Machine with Motion Sealer:

Max Door Size:

|

Width 1250mm, Length 2500mm

|

Door Weight:

|

10-90 kg

|

Sealing Power Consumption:

|

Approx. 6.5kW

|

Shrinking Tunnel Size:

|

L2600mm × W1600mm × H1300mm

|

Film Type:

|

PE film, 30-45 microns in thickness

|

Conveyor Speed:

|

Adjustable from 0-12 meters per minute

|

Power Supply:

|

380V, 50Hz, 3-phase

|

Benefits for Manufacturers

-

Enhanced Productivity: The machine’s automatic operation reduces the need for manual labor, allowing for faster packaging without compromising quality.

-

Professional Finish: Thanks to the motion sealer, the doors are tightly wrapped with a smooth, clean finish that enhances their presentation.

-

Reduced Energy Costs:The efficient heating system in the shrink tunnel minimizes energy consumption, making it an eco-friendly and cost-effective option for manufacturers.

-

Flexibility:Its adjustable features make it adaptable to a wide range of door sizes and packaging materials, ensuring manufacturers can meet diverse client needs.

For manufacturers looking to streamline their packaging process, the Door Shrinking Machine with Motion Sealer offers a powerful solution. It delivers high-quality packaging, integrates into automated production lines, and enhances overall productivity. With its advanced features and energy-efficient design, this machine is an excellent investment for modern manufacturing facilities.